Formlabs Form 4: Maximise Your 3D Printing Potential

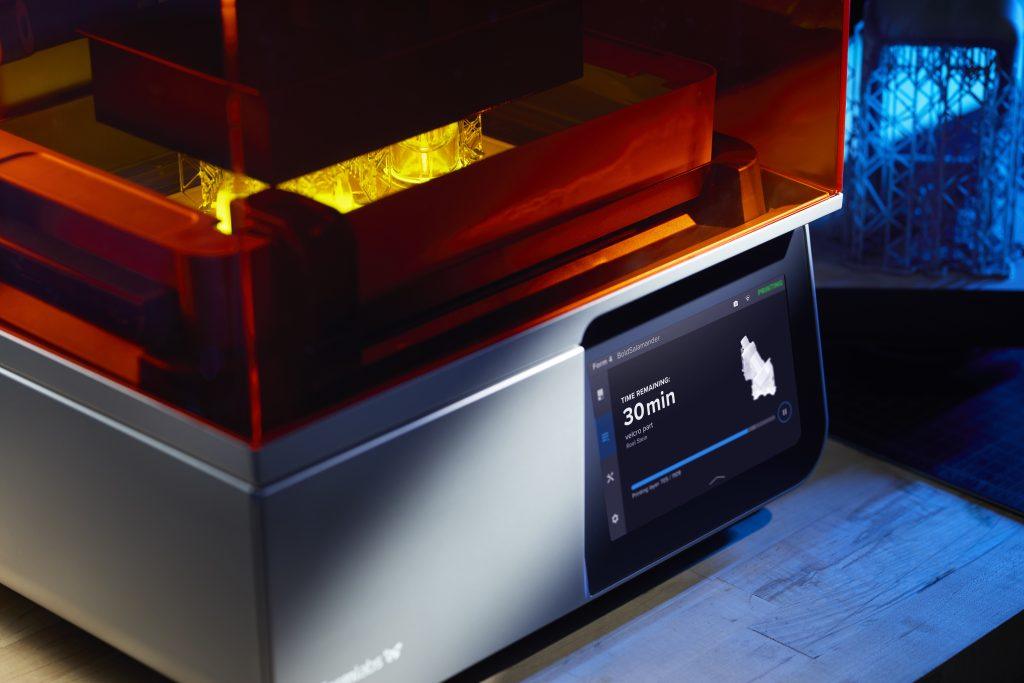

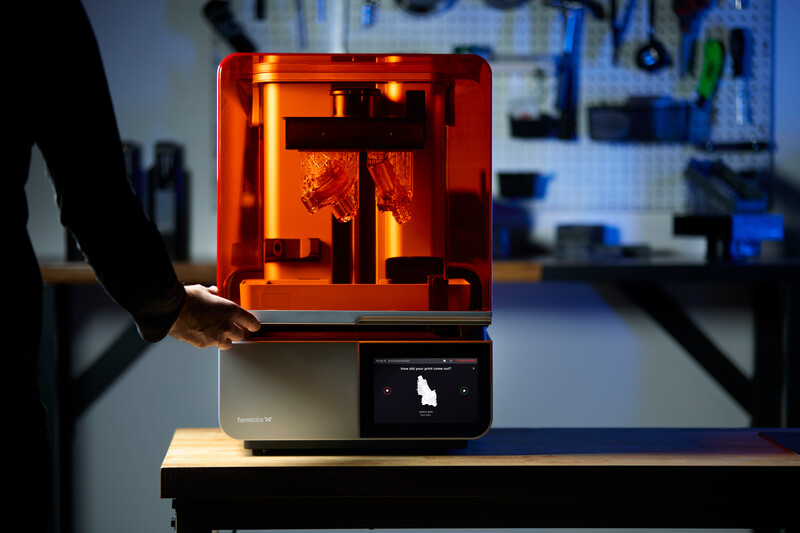

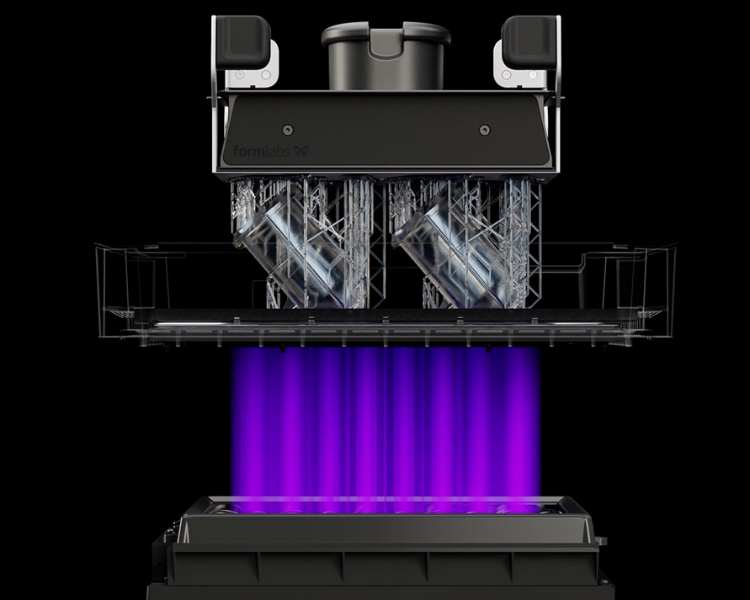

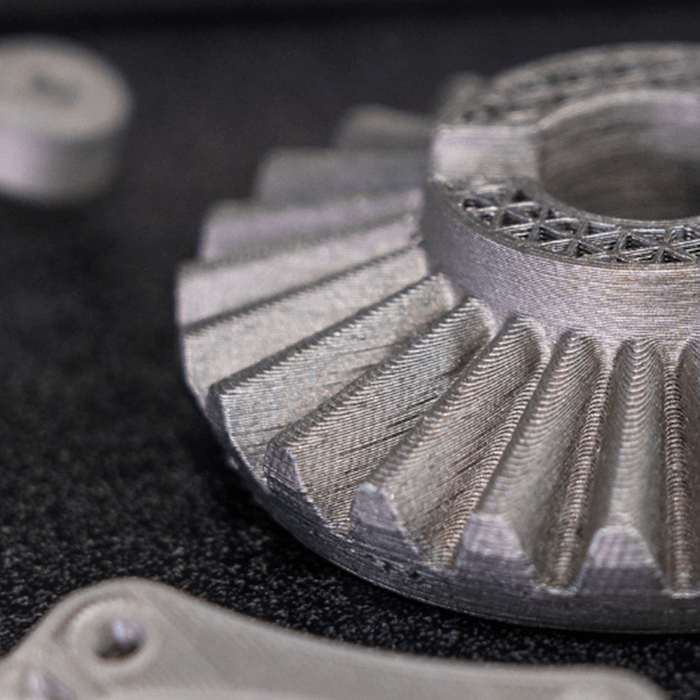

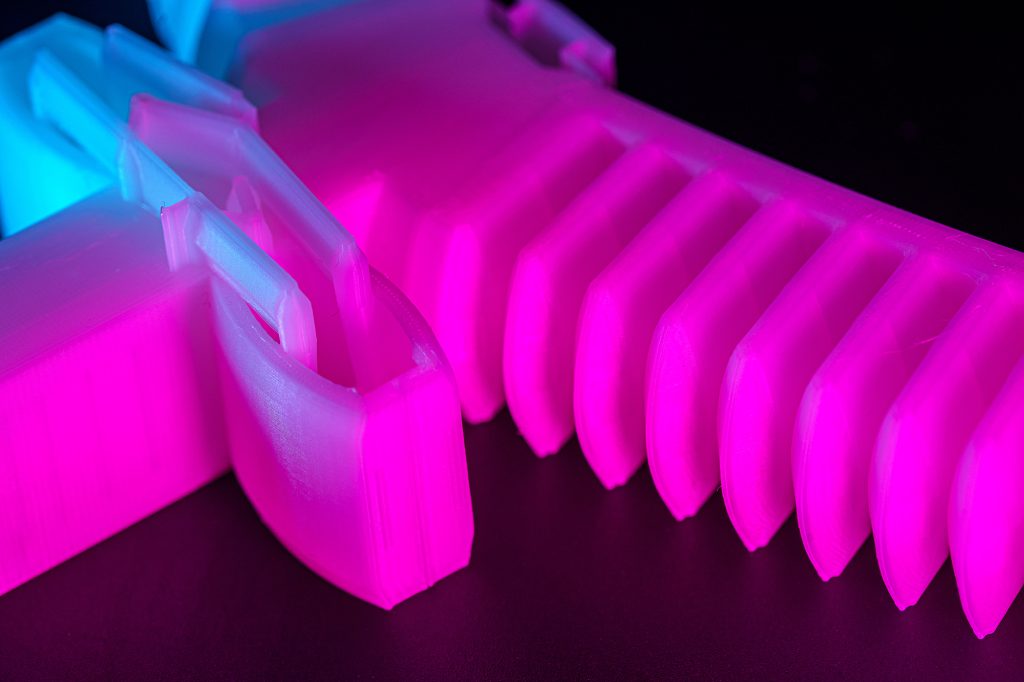

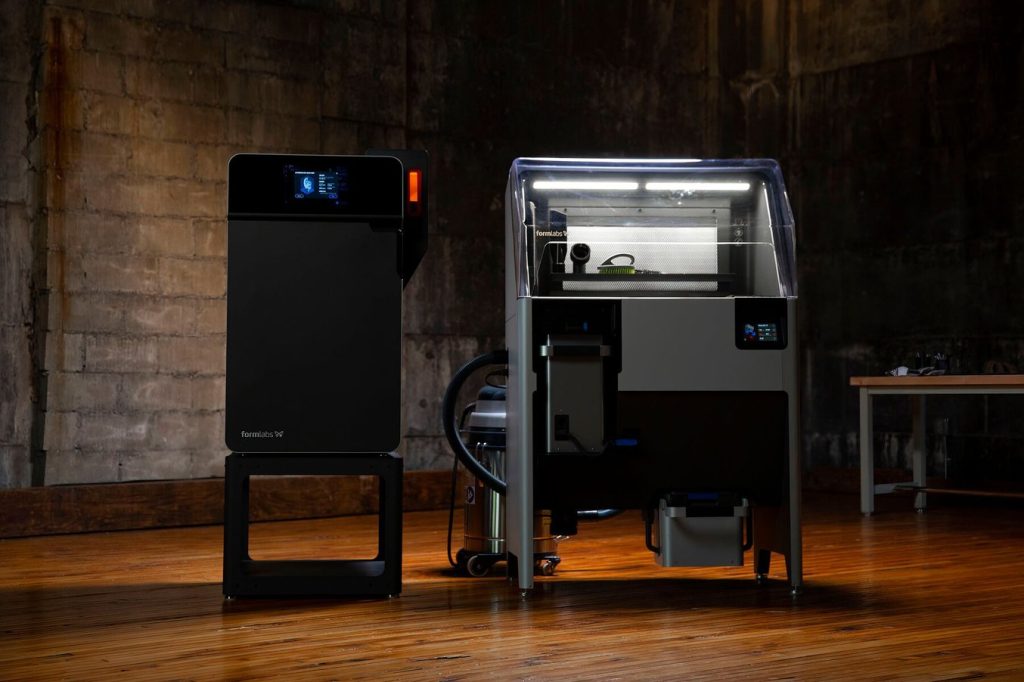

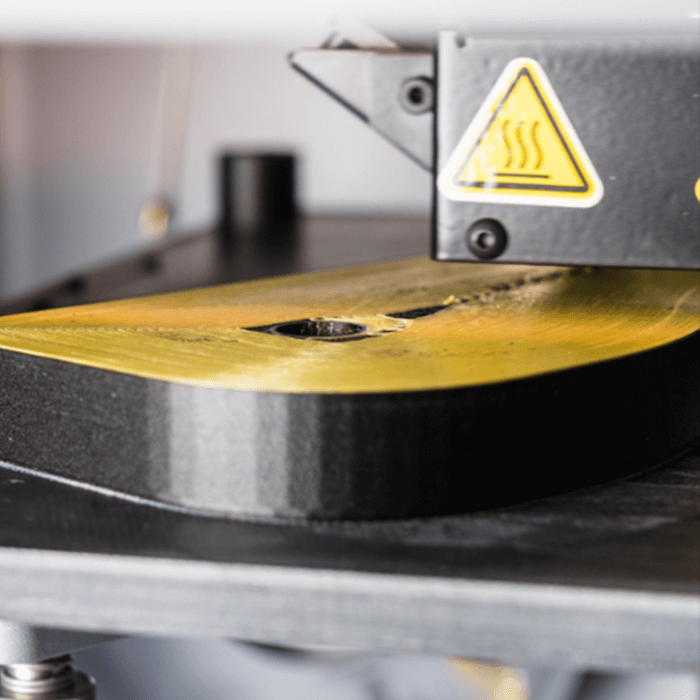

The Formlabs Form 4 can complete builds in under two hours with 50 μm resolution, a significant improvement over the now-discontinued Form 3. It supports over 20 materials while maintaining a 98.7% success rate and features a build volume 30% larger than previous models. Product teams, manufacturers, and service providers

Formlabs Form 4: Maximise Your 3D Printing Potential Read More »