Formlabs Low Force Display, The New Form 4 Print Engine

The arrival of the new Formlabs Form 4 series has also introduced us to their brand new print engine, Masked Stereolithography (MSLA). This new technology not only rapidly increases print speeds, but also preserves and improves the quality of it’s final prints. Let’s break down what this technology means for 3D printing…

Key Features

- LCD Technology Breakthrough

- Rapid Printing Speeds

- Improved Printer Specs

What Is LFD Exactly?

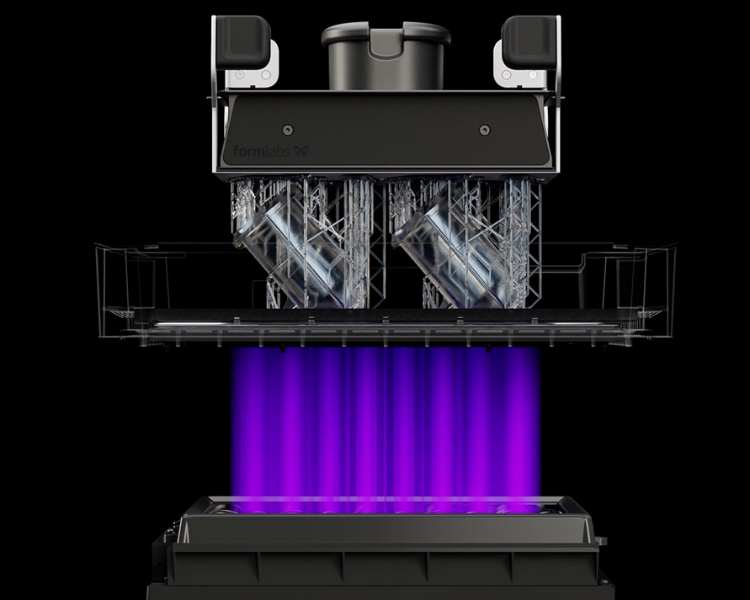

Formlabs has released the Form 4 and Form 4B 3D printers with a proprietary Low Force Display (LFD) print engine that combines LCD and SLA technologies to create a new print process they describe as masked stereolithography (MSLA).

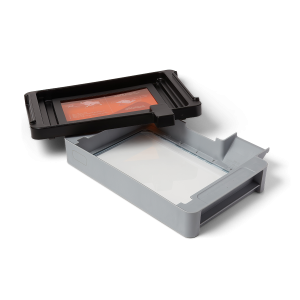

The LFD engine has six custom hardware subsystems, including 17 optical components, a patented release texture, and a flexible film tank to deliver unprecedented speed, reliability, print quality, and material performance.

These elements are interconnected in inverted SLA and enhancing one can come at the cost of another, but the Formlabs Form 4 manages to strike an optimal balance, delivering impressive results across the board thanks to LFD technology and engineering-grade resins.

An LCD Breakthrough

The Form 4 has a custom LCD at its core, but its Low Force Display (LFD) print engine sets it apart from any other LCD, DLP, or laser SLA printer on the market.

The result? The Form 4 is the fastest desktop SLA printer you can buy, delivering the best consistency at speed. Most modern SLA printers achieve similar average print speeds of 20-40 mm/hour for their general-purpose materials, but only the Form 4 does so with such an exceptional balance of print quality. It also accommodates larger part sizes – a combination unmatched by competitors.

Beyond the custom LCD, Form 4 boasts a powerful backlight, compatibility with over 37 industry-leading materials, integrated heating, integrated force sensing, debris detection, and more, and it is this synergistic combination of technologies that enables the Form 4 to deliver industrial-grade print speeds and quality.

Get Most Prints Done in 2 Hours

Here are some print speed examples:

An average print speed of 40 mm/h and a maximum print speed of 100 mm/h (at a 100-micron layer height) means you can quickly produce parts that would take much longer on other SLA 3D printers.

Formlabs claims that most prints, using the 80th percentile print height of 53mm and a 100-micron layer height, can be completed in less than 2 hours – a staggering number that will transform prototyping in all industries.

The post-processing stage is also optimised for speed and ease of use with the quick-release Build Platform Flex, Form Wash, and Form Cure. You can process your prints in just 15 minutes, further reducing the overall turnaround time.

Form 4 Printer Specs

- Low Force Display (LFD) technology.

- Smoothest surfaces with 50 μm pixel size and advanced pixel smoothing for sub-pixel resolution.

- Accurate assemblies with tight tolerances for precise fit.

- Build Volume (W x D x H) 20.0 x 12.5 x 21.0 cm | 7.9 x 4.9 x 8.3 in.

- Layer Thickness (Z Resolution) 25 – 300 microns.

- XY Resolution 50 microns.

- Average Print Speed (100 µm layer height): 40 mm/h.

- Maximum Print Speed: 100 mm/h.

- Resin Tank Lifetime 75,000+ layers with any Formlabs material.

- Printer Weight 18.3 kg | 40.4 lb.

- Printer Dimensions 39.8 x 36.7 x 55.4 cm | 15.7 x 14.5 x 21.9 in.

- Warranty and Service – A one-year warranty is included, and paid service and extended warranty options are available.

- Software Compatibility – Windows 7 and up, macOS 10.12 and up.

- File Types Accepted – STL, OBJ, 3MF.

Summing Up

Traditional SLA printers use a laser system to selectivity cure photosensitive resin layer-by-layer, and LCD printers use a UV LCD screen to mask and cure the layers – the Form 4’s LFD print engine combines elements of both technologies for superior print speed and final part quality with SLA-like optics, resin handling, and a fantastic material portfolio.