Automation has become an integral part of various industries, from manufacturing to healthcare, as it allows for increased efficiency and precision in tasks. Traditional grippers have been used for automation purposes; however, they have limitations when it comes to handling delicate objects or adapting to irregular shapes. This is where soft robotics grippers come in, which are made of flexible materials that can conform to different objects and provide a gentle grip. These types of grippers have been gaining popularity in recent years due to their versatility, but they often require electronics for control and operation. The University of California San Diego has developed a ground-breaking solution by creating an electronics-free 3D printed soft robotics gripper with fluidic logic technology that could revolutionise the field of automation.

The 3D Printed Gripper

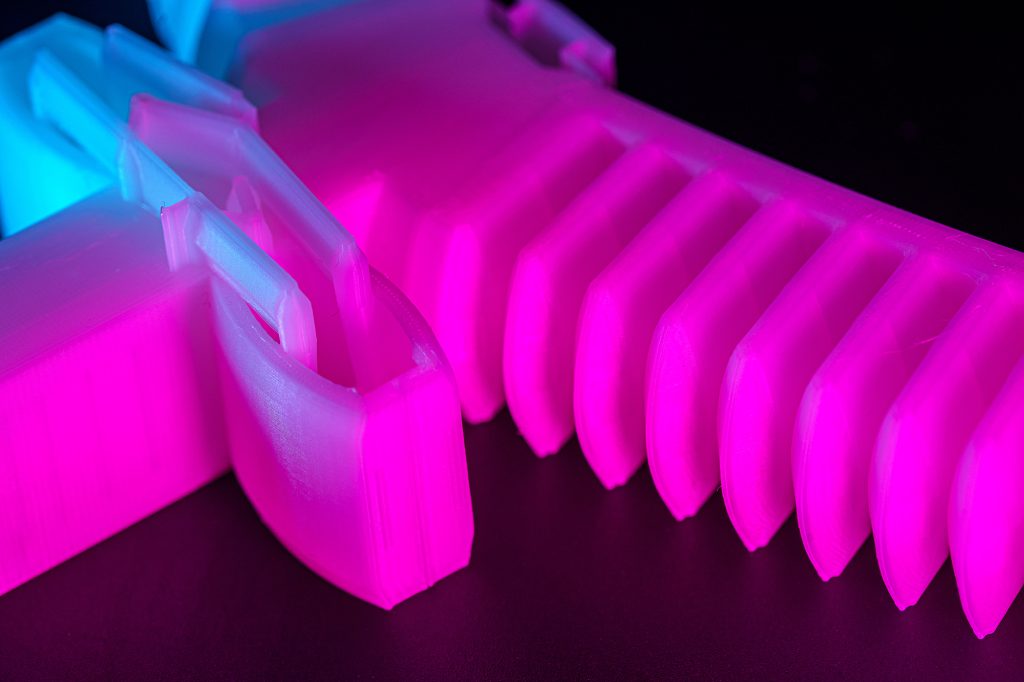

The 3D printed gripper developed by the University of California San Diego represents a potentially transformative innovation in the field of automation. Unlike traditional grippers that are often rigid and require complex electronics, this soft robotics gripper is electronics-free and relies on fluidic logic technology for its operation. The gripper is made from a flexible material that allows it to conform to the shape of objects, making it ideal for handling delicate items. And fluidic logic technology enables it to perform complex tasks without the need for any electronic components, making it more reliable and cost-effective than traditional grippers.

The 3D printed soft robotics gripper has several advantages over traditional grippers. Firstly, its flexibility allows it to handle a wide range of objects with varying shapes and sizes. This makes it ideal for use in industries such as food processing, where delicate items like fruits and vegetables need to be handled carefully to avoid damage. Secondly, its electronics-free design means that it is less prone to failure than traditional grippers that rely on complex electronic components. This makes it more reliable and reduces maintenance costs.

The fluidic logic technology used in the 3D printed soft robotics gripper is also worth noting. Fluidic logic uses fluids instead of electronic signals to control the movement of the gripper’s fingers. This makes the gripper more energy-efficient and reduces the risk of electrical interference or malfunction. Additionally, because there are no electronic components involved, the overall cost of production is reduced.

The development of this 3D printed soft robotics gripper has been a collaborative effort between UC San Diego and BASF corporation. BASF provided expertise in materials science and additive manufacturing techniques, while UC San Diego contributed their knowledge in soft robotics and fluidic logic technology. This collaboration has resulted in a product that combines cutting-edge technologies from both fields.

Applications of the 3D Printed Gripper

The 3D printed gripper developed by the University of California San Diego has a wide range of applications in various industries. One of the significant advantages of this gripper is its ability to handle delicate and irregularly shaped objects without causing any damage. Here are some examples of its potential applications:

Manufacturing

The manufacturing industry requires automation solutions that can handle different shapes and sizes of products with precision. The 3D printed gripper can be used for pick-and-place operations, sorting, and assembly tasks. It can also handle fragile components such as electronic parts, glass, and ceramics without causing any damage.

Food

The food industry demands high levels of hygiene standards when it comes to handling consumable products. The 3D printed gripper’s soft and flexible nature makes it an ideal solution for handling delicate food items such as fruits, vegetables, and baked goods without causing them damage.

Medicine

The medical industry requires automation solutions that are safe to use around patients and medical equipment. The 3D printed gripper’s soft robotic technology makes it a perfect fit for handling surgical instruments, test tubes, vials, and other medical equipment.

Agriculture

The agriculture industry requires automation solutions that can handle different types of crops with care. The 3D printed gripper’s gentle yet firm grip makes it an ideal solution for harvesting fruits, vegetables, and flowers without damaging them.

Collaboration for Further Development and Commercialisation

The development of the 3D printed soft robotics gripper by UC San Diego has caught the attention of BASF corporation, a leading chemical company. The two entities have joined forces to further develop and commercialize the technology for wider use in automation. The collaboration aims to improve the design and functionality of the gripper, making it more versatile and adaptable for different applications. BASF brings its expertise in materials science and engineering to the table, which complements UC San Diego’s knowledge in soft robotics and fluidic logic. Through this partnership, they hope to create a product that meets industry demands for precision, speed, and efficiency. Additionally, they are working on optimizing production processes to make the gripper more cost-effective and scalable. The success of this collaboration could pave the way for future joint projects between academic institutions and private companies in advancing automation technology. Ultimately, this partnership is an example of how interdisciplinary collaboration can lead to ground-breaking innovation, with the potential to benefit society as a whole.

Future Possibilities and Potential Impact

The development of electronics-free soft robotics grippers has opened up a whole new world of possibilities for automation. With the ability to handle delicate and irregularly shaped objects without causing damage, these grippers can be used in a wide range of industries, from manufacturing to healthcare. In the future, one can expect to see even more advanced versions of these grippers that are capable of performing more complex tasks. For example, researchers are already working on developing soft robots that can sense their environment and respond accordingly. This could lead to the creation of robots that are able to navigate through cluttered environments or work alongside humans in collaborative settings. The potential impact of this technology is enormous. Entire industries could be revolutionised, with improved efficiency across the board. As collaboration between academia and industry continues, we can look forward to even more exciting developments in the field of soft robotics and automation.