The History of 3D Printing: A Journey of Innovation and Transformation

The Dawn of a New Era

The history of 3D printing, also known as additive manufacturing, begins in the 1980s. This transformative technology’s origins lies with the work of from Japan, who secured the first 3D printing-related patent in 1981. His device, capable of hardening photoreactive polymers with UV light to create three-dimensional models, sparked a shift in design capabilities. Kodama’s approach was ground-breaking at the time because it represented a shift from the traditional manufacturing methods, where material is removed to create an object, to a novel method where additive processes create objects from the ground up.

Hideo Kodama, 3D printing pioneer

Initially designed as a tool for producing prototypes and models, Kodama’s invention ushered in an era of rapid, cost-effective prototyping. His single-beam laser curing approach transformed the product development process, making it faster and more efficient.

The Rise of Stereolithography

In 1984, three years after Kodama’s ground-breaking invention, the world saw the introduction of a 3D printing technique called Stereolithography (SLA). A team of French inventors led by Alain Le Mehaute filed the first patent for the SLA method, which, much like Kodama’s invention, relied on UV lasers’ crossing paths to harden photopolymers.

Specifically, stereolithography is rooted in the process of curing a photoreactive resin with a UV laser, which travels across the resin’s surface to produce each layer of the 3D object in turn. The layers are then stacked on top of one another to produce the final 3D structure. Hull’s revelation lay in the hitherto unseen precision and detail that his stereolithography techniques could offer.

The idea had potential, but it was perhaps a bit too ahead of its time; the patent application was abandoned by General Electric due to a perceived lack of significant business prospects.

Little did they know, however, that their dismissal of this invention would pave the way for another visionary – Chuck Hull, an American engineer . A mere three weeks after the French team’s patent application, Hull filed his own for a similar technology. His vision was welcomed, and he himself went on to coin the term “stereolithography” in 1986. Today, stereolithography is one of the most commonly used 3D printing techniques worldwide.

The Advent of the STL File Format

Alongside the development of his hardware, Hull contributed significantly to the software side of 3D printing. Specifically, he introduced the STL file format – a digital language universally readable by 3D printers. It works by simplifying 3D models into a collection of triangular facets which can then be easily interpreted by the printer.

This marked a significant step in the evolution of 3D printing. With this software innovation, anyone with a digital 3D model and the appropriate software could create physical objects. 3D designs could be effortlessly translated from the digital realm to the physical, paving the way for the additive manufacturing revolution that followed.

The Emergence of Sintering Techniques

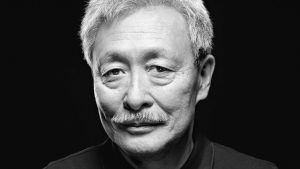

The late 1980s saw the emergence of a new wave of 3D printing techniques that expanded upon the foundational work of Kodama and Hull. In 1987, Carl Deckard, an inventor with bold aspirations, filed a patent for. His technique used a CO2 laser to fuse powders into a solid structure. Instead of liquid resins, SLS uses powdered material, which can be anything from nylon, ceramics, glass, to even some metals. A laser is used to selectively fuse the powder at specific locations, corresponding to a cross-section of the final part, which in turn solidifies the material to create a layer of the 3D part. Layers are stacked on top of each other and the print is produced. The versatility and practicality of the SLS process led to its widespread adoption, and it became the most widespread 3D printing technology across a variety of industries.

Direct Metal Laser Sintering: Bringing Metal to 3D Printing

In the same period as Carl Deckard, a German additive manufacturing company named EOS GmbH emerged, focusing primarily on developing laser sintering techniques. The company’s crowning achievement was the development of Direct Metal Laser Sintering (DMLS) techniques – a continuation of the SLS method that expanded the range of materials usable in 3D printing to include metals. DMLS is capable of creating highly complex structures in a range of metals, including stainless steel, aluminium, titanium, and even precious metals like gold and silver. This technique enables 3D printing to meet the requirements of industries like aerospace and medical, which often require precise, durable metal parts. This was a major breakthrough as it broadened the scope of 3D printing to industries where metal parts were a necessity.

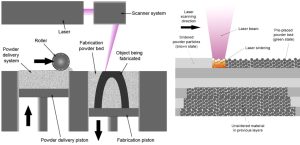

Fused Deposition Modelling: A Consumer-Grade Innovation

Parallel to these developments, a new method of 3D printing was being pioneered elsewhere. Fused Deposition Modeling (FDM), the brainchild of S. Scott Crump, was invented and patented in 1989. FDM employed an entirely different approach to additive manufacturing: instead of using light or lasers, it involved heating and extruding a thermoplastic material layer by layer to form the desired object. FDM made 3D printing more accessible to consumers due to its lower cost, safety, and simplicity, as compared to techniques like SLA or SLS.

Crump commercialised this technique through Stratasys, a company he co-founded with his wife, Lisa.

3D Printing for the Masses

The 1990s and early 2000s marked a period of accelerated growth and expansion in 3D printing technology. Whilst high-end 3D printers became increasingly sophisticated, consumer-grade 3D printers were becoming more accessible and affordable. This democratisation of technology spurred a surge in interest and adoption among hobbyists and professionals alike.

A RepRap printer with its child

One significant milestone during this period was the launch of the RepRap project in 2005. This open-source initiative set out to create a low-cost, self-replicating 3D printer — a concept that promised to make 3D printing accessible to everyone. Adopting FDM technology, the RepRap project inspired the creation of countless affordable and efficient desktop 3D printers, further fueling the expansion of 3D printing into homes and offices worldwide.

The Impact on Manufacturing and Beyond

3D printing has now, relatively speaking, come of age, with its influence reaching far beyond mere novelty. Additive manufacturing techniques are transforming manufacturing processes by reducing tooling costs, accelerating the pace of product development, and offering a more sustainable alternative to traditional manufacturing methods. Looking forward, 3D printing holds immense potential. It has the potential to revitalise local economies by reducing the need for outsourcing, emphasising design and computer science skills over manual labour, and encouraging localised production. Supply chain shifts could also significantly reduce global greenhouse gas emissions, marking a step towards a greener future.

The most exciting chapters of this remarkable technology are yet to be seen; human ingenuity will no doubt continue to push the boundaries of what’s possible with 3D printing, and here at Additive-X, we hope to play our part.