Lynxter represents a new generation of industrial 3D printing manufacture. They are leading the way with the S600D – their first modular 3D printer capable of printing with silicones, thermoplastics, and pastes.

A bold vision

- In 2016, a group of engineering graduates created Lynxter with a vision to disrupt traditional design, production, and supply paradigms by creating a smarter, more professional 3D printer.

- After winning an innovation competition and catching the eye of Airbus, Lynxter launched their inaugural machine in 2018 to widespread acclaim.

- They continue to push the boundaries of additive manufacturing technology with their pioneering tool-heads and use of liquid materials.

“Open” technology

- All Lynxter products are passionately designed and manufactured at their workshop in Bayonne, France.

- They support an open door policy with their technology, sharing their 3D printing procedures and research, and encouraging collaboration with their team to experiment with new materials.

The S600D – the universal 3D printer

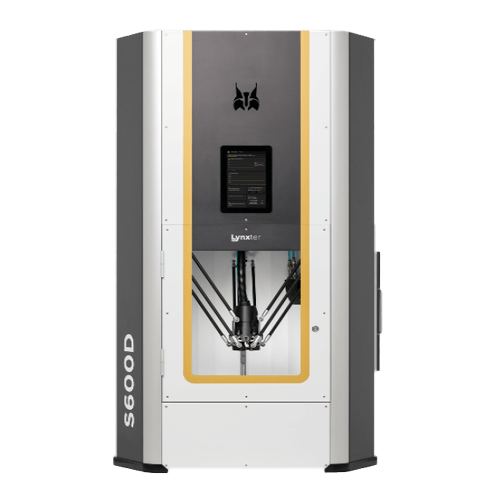

- The flagship Lynxter S600D is an open additive manufacturing ecosystem equipped with a modular quick-change toolhead system, enabling the widest range of materials available on the market today.

- The S600D offers a large print volume (⌀390mm x 600mm), exceptional speed, unrivalled print quality, a comprehensive web interface for seamless remote control, and automatic calibration for a hassle-free user experience.

- Each tool-head offers a multitude of printing possibilities including single/dual material extrusion and both FDM/FFF and LAM processes.

- Users can switch effortlessly between filament, liquid, and paste printing, depending on the project’s needs.

- The S600D supports a wide range of materials, including thermoplastics, silicones, and ceramics, making it applicable in diverse sectors such as aerospace, automotive, medical, R&D, industrial manufacturing, and tooling.

Leadership in silicone printing

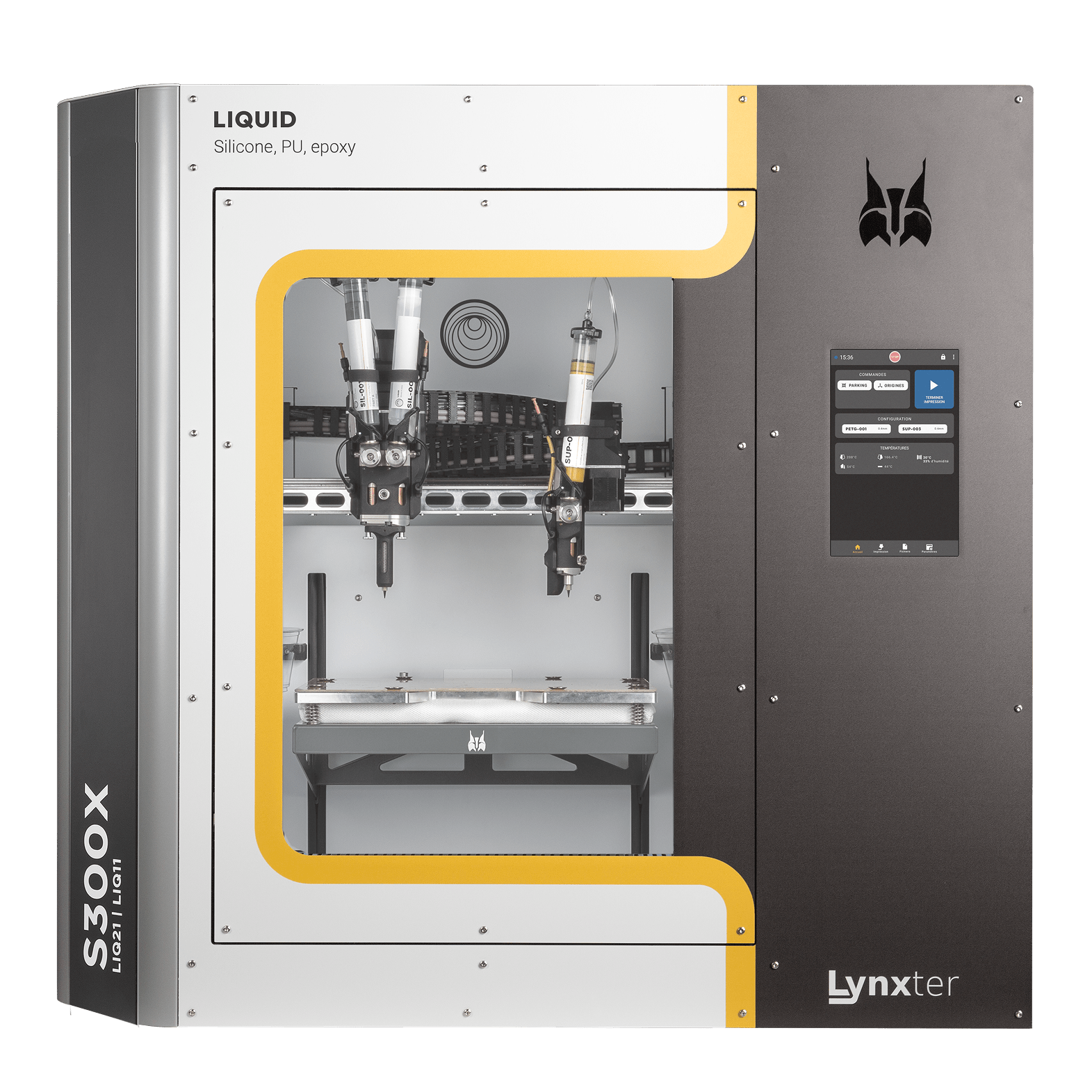

- Lynxter leads the market in silicone printing capabilities with their new S300X.

- The S300X features an integrated soluble support system, IDEX technology, and large-cartridge capacity, facilitating easy printing of medical and industrial-grade silicone and polyurethane parts.

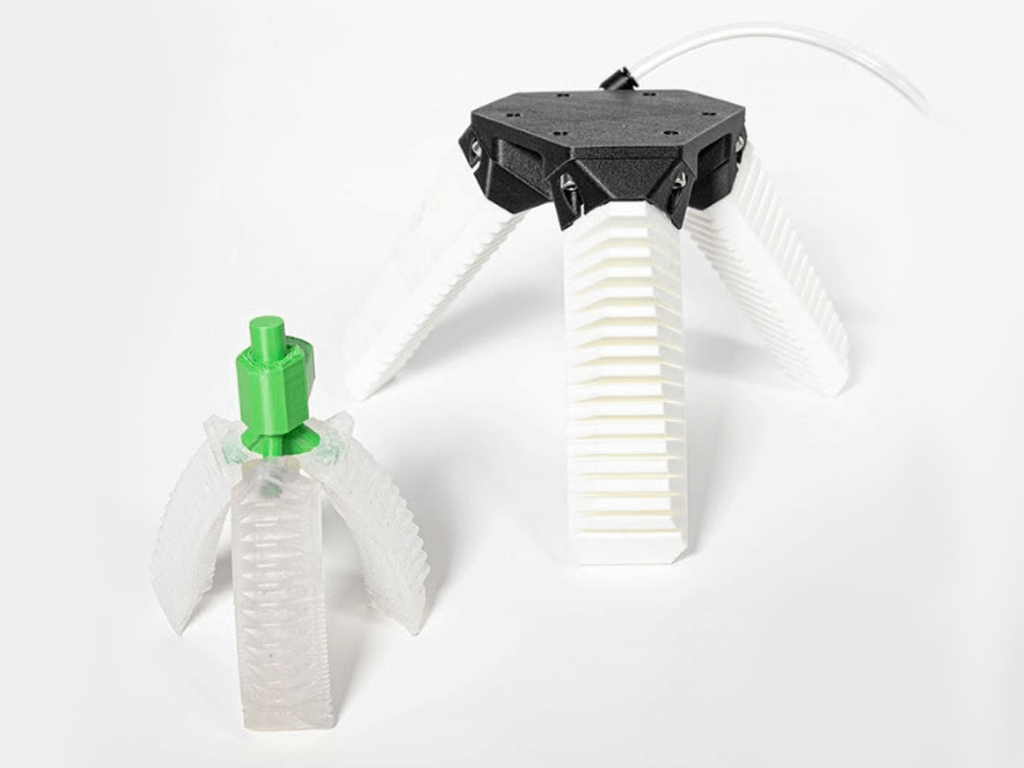

- Industrial applications include the production of custom seals, surface treatment masks, emergency repairs, and soft robotics.

- The printer uses RTV2 medical-grade silicones (5, 10, 25, 40 shA) which maintain their chemical and mechanical properties for safe and reliable medical applications such as orthopaedic and orthoplastic device production, as well as custom prostheses and orthoses.

Additive-X | Your Official Lynxter Reseller

Want To Explore Lynxter Solutions?

Talk To Us With One Of Our Lynxter Experts At A Time That Suits You

3D Printing from Lynxter Printer Range

Lynxter S600D

Universal 3D Printer with quick-change toolhead technology to allow printing in filaments (thermoplastics), liquids (silicones), pastes (ceramics) in high quality.

Technology: FFF, LAM

Build Volume: 390 mm x 600 mm

Minimum Layer Resolution: 50 μm

Materials Available: PP, PEKK, PETG, PA Carbon Fiber, PC, TPU 85 ShoreA, ABS Carbon, ABS, ESD, PC, PET, PETG Carbon, PLA, Silicone RTV1 34 ShoreA, Silicone RTV1 57 ShoreA, Silicone RTV2 40 ShoreA, Silicone RTV2 25 ShoreA, Alumina, Cordierite, Zircon,Clay, Stoneware, Porcelain

Opensource: Yes

Cost Of Machine: Price on Request

Lynxter S300X

A compact, reliable and robust industrial silicone 3D printer with integrated support printing technology for unlimited shape design.

Technology: FFF, LAM

Build Volume: 300 mm x 250 mm x 200mm

Layer Height: 100μm to > 1mm

Materials Available: Silicone, RTV2 medical

Opensource: Yes

Cost Of Machine: Price on Request

Printing Examples

User Stories

See how the S600D prints in silicones, thermoplastics and ceramics

Lynxter’s S600D

Lynxter Multi-Material 3D Printing

The S300X Idex Silicone Printer

Additive-X | Your Experienced Additive Manufacturing Partner

Benchmarks • Demos • Applications Engineering

Get in touch with Additive-X to find out how you can benefit from a multi-material, open additive manufacturing ecosystem, made for Industry 4.0

News & Blog

Can a Silicone 3D Printer Be Utilised in Healthcare Product Development?

Can a Silicone 3D Printer Be Utilised in Healthcare Product Development?

Silicone 3D Printing: How it could change the medical field

Lynxter S300X Release: Next Level Silicone Printing Is Here

3D Silicone Printing: How It Works & Ideal Applications

3D Printing Silicone For Soft Robotics Is Possible With Lynxter