How to Care for Your 3D Printer: Part 3 – Axis and Guide Checks

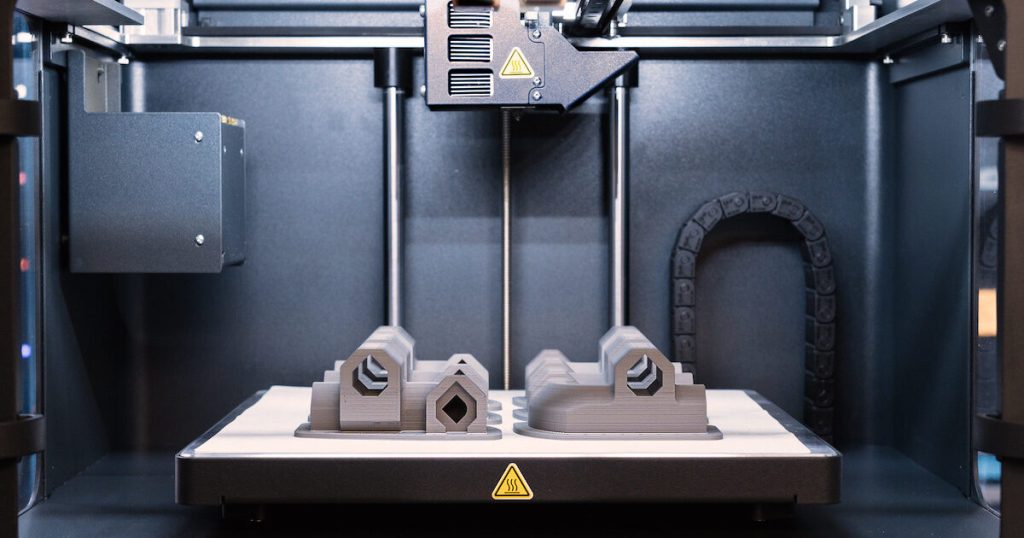

The axes of a 3D printer, typically referred to as the X, Y, and Z axes, along with their respective guides, are fundamental to the machine’s operation. They are responsible for the precise movements that the printer head makes to create the 3D printed object layer by layer. As such,

How to Care for Your 3D Printer: Part 3 – Axis and Guide Checks Read More »