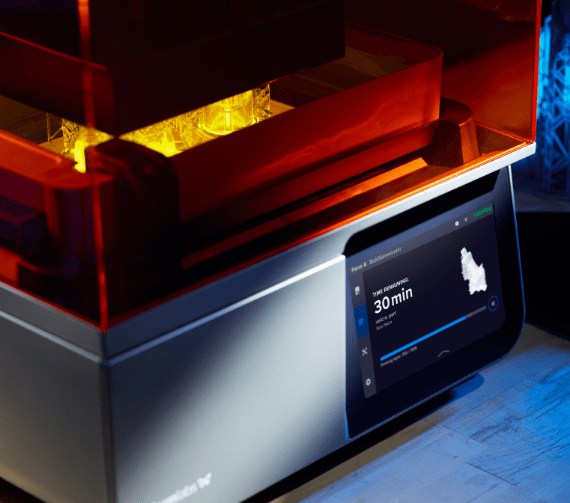

SLA a 3D Printing Technology

Resolution

High

Investment

Low

Stereolithography (SLA) 3D printers work by using a laser to cure (solidify) a liquid resin into a hardened plastic in a process called photopolymerisation. SLA prints have great accuracy and print quality with a noticeably smooth surface finish and minimal layer lines. Formlabs have taken the technology to the next level on the Form series of 3D printers with their Low Force Stereolithography (LFS) which delivers lower peel forces and therefore an improved surface finish. You don’t just have to print at high resolution, you can also print fast by switching layer height in PreForm. Choose 25, 50, 100, 160, and 200 micron Z layer height to get the best result depending on your part and your material.

What can SLA print?

Why choose Formlabs SLA?

Resin cartridge system

Auto-dispenses resin in to the tank for printing - switch material by swapping cartridge and tank

Light-touch supports

Supports are easy to break off, leaving minimal marks which you can remove with light sanding

Office and workshop-friendly

Compact footprint for desktop (3+ 3B+) or benchtop (3L, 3BL), for office, lab, workshop or shop floor environment

Streamlined post-processing

Easy and automated - cleaning uncured resin in the Form Wash, post-curing for optimal material properties in the Form Cure

Wide range of materials

35 functional resins are available for the Form series with more in development

Do you already own an SLA 3D printer?

We can show you why SLA owners upgrade to SLA for next-level additive manufacturing

Printing Examples

Relevant Printers

Formlabs Form 4

Formlabs Form 4B

Additive-X | Working with Formlabs SLA printers since 2014

Formlabs Platinum Partner • UK Authorised Reseller • ISO9001:2015 Certified

Partnering with Additive-X Means that you will benefit from our long standing relationship with Formlabs Inc. Our Experienced Staff are on hand for sales, customer service and tech support. Supporting you continuously throughout your Formlabs SLA 3D printing journey.

FAQ’S

Commonly asked questions about SLA 3D printing

Engineers, designers, manufacturers, and many more choose SLA 3D printing for its fine features, smooth surface finish, ultimate part precision and accuracy, and mechanical attributes like isotropy, watertightness, and material versatility.

Yes you can leave a finished print on the build platform on the printer with the printer cover closed – the orange plastic of the cover provides protection from UV light.

With a Dashboard account you can track and manage your jobs and multiple printers. You can receive notification when prints start or finish, and when you need to attend to one of your printers. Dashboard is a tool which puts you in control; use it to manage a fleet of Formlabs Low Force SLA or SLS printers remotely, including their resin tank and material usage.

It depends on the size, geometry etc of your print, but if you load an .STL file in to PreForm it will tell you how much resin it will take to print. As an example the classic Formlabs rook (chess piece) is 55mm high and uses approx 11 ml of resin, so that makes 90 rooks from a litre of resin. PreForm is free to download, so you can do some calculations before you invest in a printer. Of course you can always send your STL file to us and we will tell you how much resin it will use as well as the estimated time to print.

Firstly you can’t refill your resin cartridge even with Formlabs resin because you might contaminate it and cause print failures. Secondly we don’t recommend using 3rd party resins because they haven’t been engineered to work with the Formlabs hardware and software – you are unlikely to have the same great SLA printing experience!

Store resin according to Formlabs guidelines. Outside of the printer or resin cartridge, resin can be stored in resin tanks for up to three months with the lid on. Storing tanks longer than the recommended time may cause leaks and damage equipment. Also bear in mind the resin tank life span depending on the resin you are using.

You can reuse resin that is in the tank after a print. Do not return resin to the cartridge to avoid potential contamination. The printer cover protects liquid resin from ambient light.

Shake resin cartridges approximately every two weeks when in storage to keep resins thoroughly mixed, and shake cartridges before printing to ensure best results.

Some users have successfully experimented with alcohol inks to create gradient, multi-color, and semi-translucent prints with Formlabs SLA printers. Contact [email protected] for resources & examples of what others have created

The Form 3L and Form 3BL both have a build volume of 33.5 × 20.0 × 30 cm (13.2 × 7.9 × 11.8 in). Both make use of the same Low Force Stereolithography (LFS) technology as the Form 3 and Form 3B, except these 3L printers are significantly larger.

The build volume of the Form 2 is 14.5 × 14.5 × 17.5 cm (5.7 × 5.7 × 6.9 in). The Form 3+ uses the same build platform, but can lift it slightly higher, for a build volume of 14.5 × 14.5 × 18.5 cm (5.7 × 5.7 × 7.3 in).

For best results, Formlabs recommends washing printed parts in isopropyl alcohol (IPA) or tripropylene glycol monomethyl ether (TPM).

Agitating parts in IPA using the Formlabs Finish Kits or automated Form Wash stations

Some of our functional resins require post-curing to achieve their optimal mechanical properties, but the standard resins do not.

Formlabs recommends always updating your computer with the latest version of PreForm and also your printers with the latest Firmware so that you can take advantage of the newest features and speed improvements that the engineers make across the board.