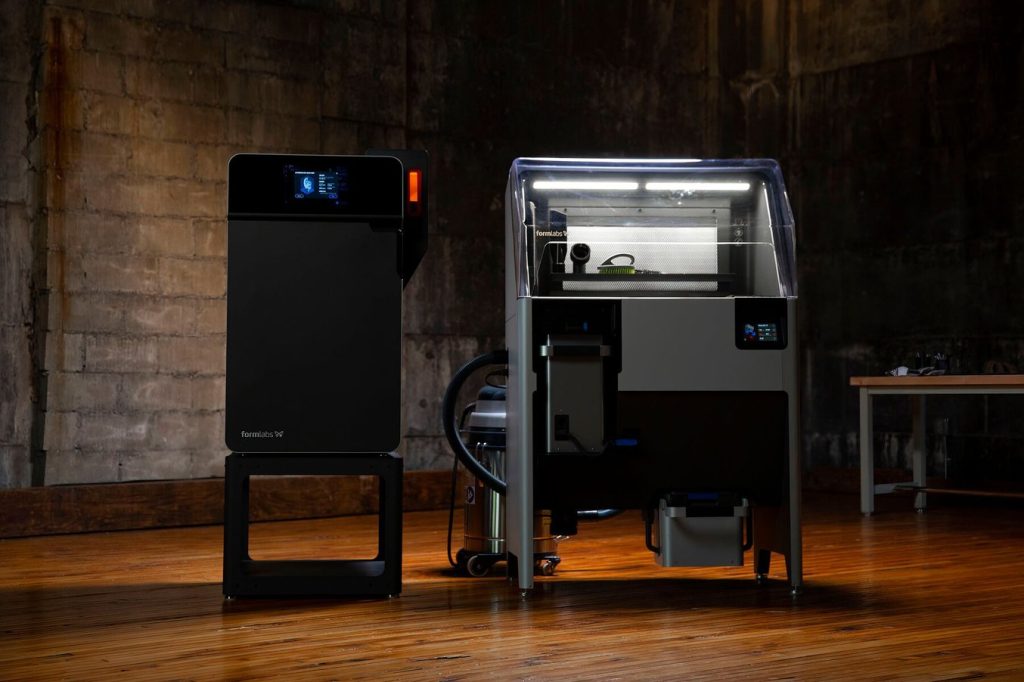

Selective Laser Sintering (SLS) printers like the Formlabs Fuse 1+ 30w use a high-powered laser to selectively ‘sinter’ powder in layers to create 3D objects.

While FFF melts thermoplastic and extrudes it through a nozzle onto a build plate, and SLA uses a laser to cure liquid resin onto the build platform, SLS additive manufacturing uses a recoat or doser assembly to spread powder for sintering with the laser.

The significant advantage of SLS is its ability to produce extreme detail and complexity without support structures because unsintered powder surrounds parts. You can fabricate complex models, including interlocking and movable elements and components with integral channels.

Another advantage of SLS is the ability to nest parts, where you can optimise part orientation to reduce wasted print volume. This lets you print a dozen or more models on the same print run, often without losing print quality.

Interested in learning more? This article compares SLS with SLA and FFF to help you decide which is the best technology for you.

SLA vs SLS

SLA printers like the Formlabs Form 3+ use a laser to cure liquid resin onto the build platform, while SLS spreads powder in layers for sintering with the laser.

SLA is superior for smaller features and capable of producing small and well-defined features, while SLS is superior for functional parts with stability and strength.

The most valuable quality of SLS is it lets you produce parts without needing support structures and print mating and moving parts in a single build, letting you complete entire functional assemblies in one print session.

SLS printers produce high part strength and dimensional accuracy due to the powder sintering together. Parts are dense with high isotropy, exhibiting property uniformity in all directions.

SLA 3D printers also produce highly isotropic parts (more so than FFF), so they share this quality. High isotropy means parts have equal strength in all directions, making them an excellent choice for functional parts and prototypes.

SLA printers offer higher detail resolution and accuracy due to the laser’s fine focus point, making it better for tight tolerances. SLA-printed parts also have a smoother surface finish – ideal for consumer-facing components.

Another reason to choose SLA is for material variations – Formlabs offers over thirty resins for hundreds of thousands of applications. These exceed the potential applications for nylon powder and serve specialist industries like medicine.

Currently, the Formlabs Fuse 1+ 30W can print Nylon 12 Powder, Nylon 11 CF Powder, Nylon 12 GF Powder, Nylon 11 Powder and TPU 90A Powder.

FFF vs SLS

FFF is the most accessible 3D printing technology on the market, offering lower adoption costs and more hardware options than SLS or SLA.

The print process starts with a filament, such as ABS or PLA filament, being melted and extruded from a nozzle. The material cools rapidly on the build plate to form a layer, and the process is repeated until the model is complete.

FFF offers customisable infill, letting you print low infill models and opening the door to structural infills that enable models to demonstrate extreme load tolerances in single or multiple directions.

SLS is a self-supporting technology, so it is not necessary to use infill patterns, although you can hollow out models to save weight.

A unique advantage of FFF is composite fibre reinforcement (CFR) with a printer like the Markforged FX20, which increases a model’s ability to withstand extreme forces by reinforcing models with strands of carbon fibre, Kevlar, or fibreglass (read this article to find out more).

FFF also offers a more extensive material portfolio, with rigid, semi-rigid, and flexible materials offering high structural stability and chemical, water and temperature resistance.

Waste is minimal with FFF because it only prints what is needed. However, unlike unsintered powder, extruded plastic must be thrown away (the Fuse Sift collects unsintered powder to be reused and recycled in another print job).

While SLS is predominantly a nylon-based print process, the Fuse 1+ 30w can print TPU 90A Powder, which is ideal for wearables, soft-touch elements, padding, dampers, seals, gaskets, orthotics, cushions, and grippers.

The case for SLS over FFF is it prints parts with high isotropy, no interlayer weakness, and does not require infills or unique materials for strength. Also, while FFF can print multiple models in one session, its capabilities do not come close to SLS, which can pack the build platform by nesting parts.

Lastly, while FFF is considered an affordable 3D printing technology, some printers can cost considerably more than SLA/SLS machines if they have unique capabilities, like the ability to 3D print silicone (e.g., Lynxter S600D).

Summing up

Choose SLS for sturdy parts with high strength and the ability to print without support structures, letting you create functional parts and assemblies, including interlocking and movable elements and components with integral channels, in one print session.

SLA is ideal for detail-rich parts with complex geometries. SLA is the better option if you need part detail, a smooth surface finish, and small features.

FFF is the most accessible 3D printing technology and can fabricate parts with varying infill and material types for various applications.

Top image credit: Formlabs.

Find out more

To find out more about support materials in 3D printing, call us on 01765 694 007 or email [email protected].