The Formlabs Form 4 can complete builds in under two hours with 50 μm resolution, a significant improvement over the now-discontinued Form 3.

It supports over 20 materials while maintaining a 98.7% success rate and features a build volume 30% larger than previous models.

Product teams, manufacturers, and service providers will find that the new Form 4 addresses speed and quality needs across prototyping and production applications.

Pro tip

The Form 4 prints photosensitive resins. Most green (uncured) parts need washing and curing for optimal mechanical characteristics. You can cover the entire workflow with the Formlabs Form 4 Complete Package.

Lightning-fast speed changes everything

You can complete most prints in under two hours, regardless of size or quantity. The Formlabs Form 4 delivers print speeds up to 100 mm per hour, making it two to four times faster than previous Form Series printers.

That speed comes from the next-generation Low Force Display™ (LFD) print engine, which uses 60 LEDs and collimating lenses to cure each resin layer instantly.

Product design teams can now complete multiple iterations in a single workday. The rapid print speed eliminates overnight waits, allowing designers to test concepts, make adjustments, and print revised versions within hours instead of days.

Stunning quality rivals injection moulding

Your parts come out with crisp edges, well-defined planes, and smooth surfaces that match injection moulded plastics. The Light Processing Unit delivers 50 μm XY resolution with pre-tuned anti-aliasing for subpixel resolution.

Parts maintain ±0.15% XY dimensional tolerances, ensuring multi-part assemblies glide together without friction.

Engineering teams value this consistency when creating complex assemblies or functional prototypes.

The dimensional accuracy ensures components mate perfectly with existing parts, making Form 4 ideal for producing tooling, fixtures, and multi-part assemblies where precision matters.

Reliability you can count on

In independent testing, the Form 4 achieved a 98.7% print success rate. Each printer undergoes 60 quality checkpoints before leaving the factory, ensuring consistent performance.

Six onboard control systems monitor temperature, resin level, print forces, and print status.

The redesigned Flexible Film Resin Tank lasts over 75,000 layers with any Formlabs resin, extending uptime and reducing operational costs. The Release Texture and tank work together to minimise peel forces for reliable printing of complex geometries.

Intuitive workflow saves time

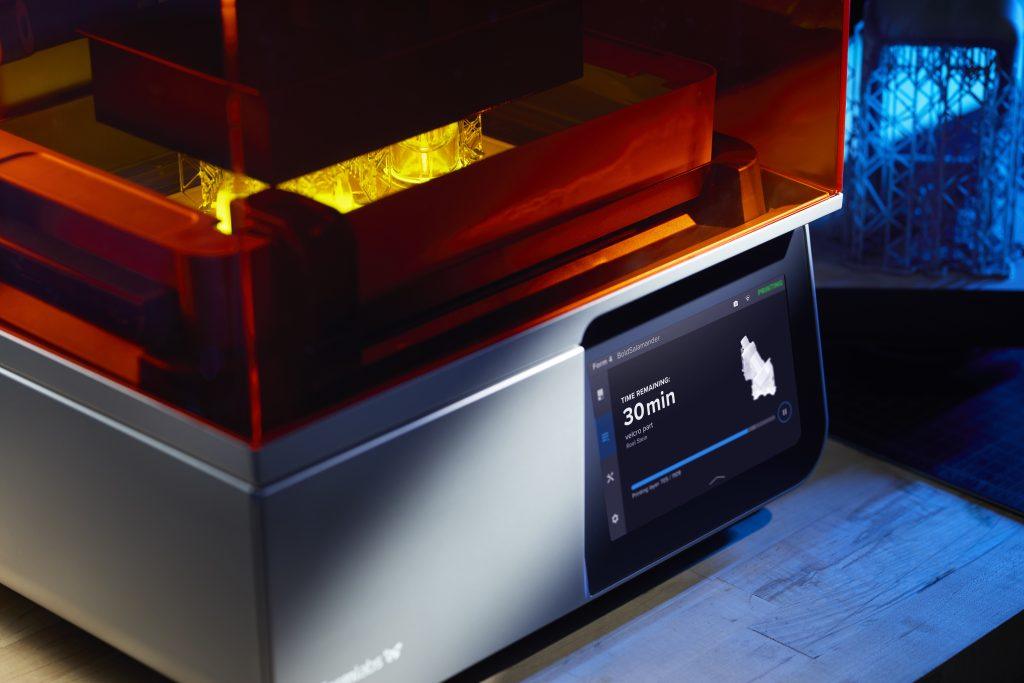

You can start printing within 15 minutes of setup. The seven-inch touchscreen displays maintenance reminders, print status, and printer readiness information. On-screen error messages include QR codes linking to support articles.

High-speed automatic resin dispensing uses smart sensors to maximise uptime. The new resin cartridge design uses 63% less plastic while delivering one litre of material, making storage easier.

The integrated resin mixer ensures excellent print quality anywhere on the build platform.

Materials versatility unlocks new applications

The Formlabs Form 4 launched with 23 validated materials, including six new resins with improved speed, toughness, accuracy, and appearance:

- General Purpose Resins V5 (Clear, Grey, Black, White) print two to five times faster than Form 3 with improved toughness and colour

- Fast Model Resin for high-speed prototyping

- Precision Model Resin for highly accurate models

- You can use materials ranging from true silicone and technical ceramic to tough and rigid formulations.

- The Form 4B biocompatible version supports 37 materials for healthcare applications

Medical device manufacturers benefit from the exceptional surface quality of Form 4 prints. The nearly invisible layer lines and smooth sidewalls create parts that look professionally manufactured rather than 3D printed, reducing post-processing time for healthcare applications.

A larger build volume for printing more parts

With a 30% larger build volume (20.0 x 12.5 x 21.0 cm), you can print more parts simultaneously without extending print time.

Unlike other printers, the Form 4’s speed remains consistent regardless of how much build platform area you use, and the Build Platform Flex with Quick Release Technology lets you remove parts without tools in seconds.

The Formlabs Form 4 ecosystem includes updated post-processing solutions. Form Wash features improved isopropyl alcohol agitation for faster cleaning, while Form Cure ensures optimal mechanical properties.

Call us on 01765 694 007 or email [email protected] to find out more about Formlabs printers.