Comparing the Markforged FX20 and X7: Key Differences

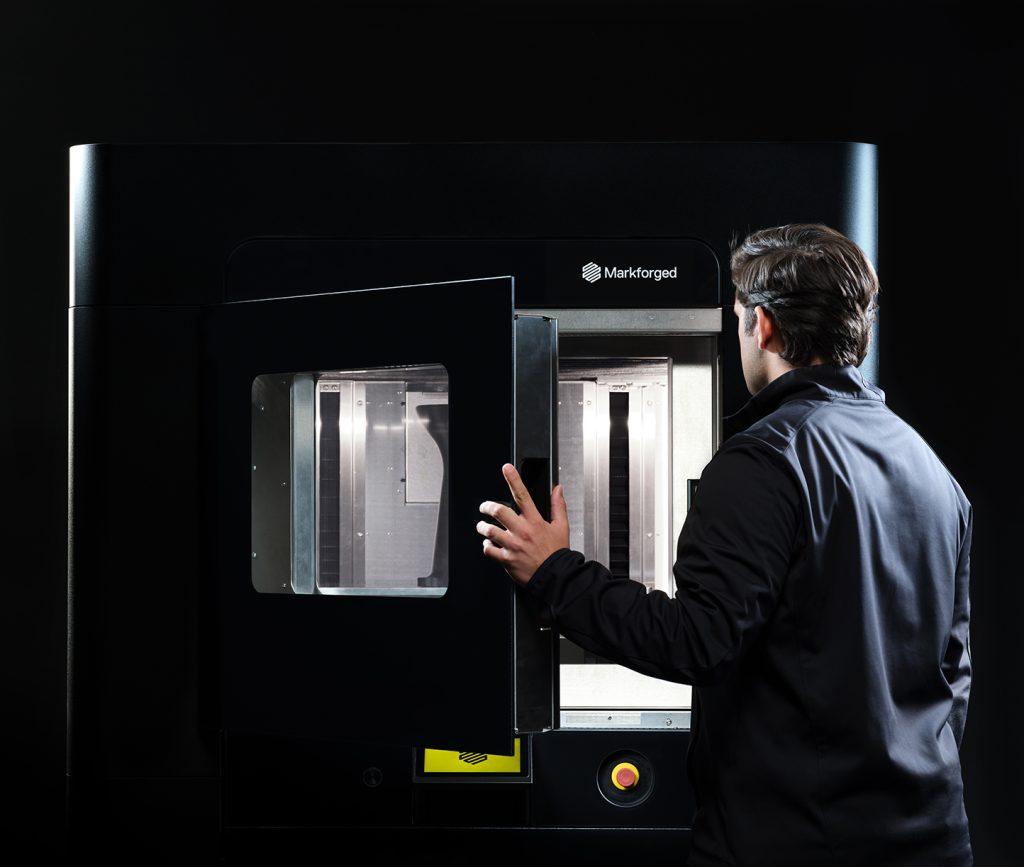

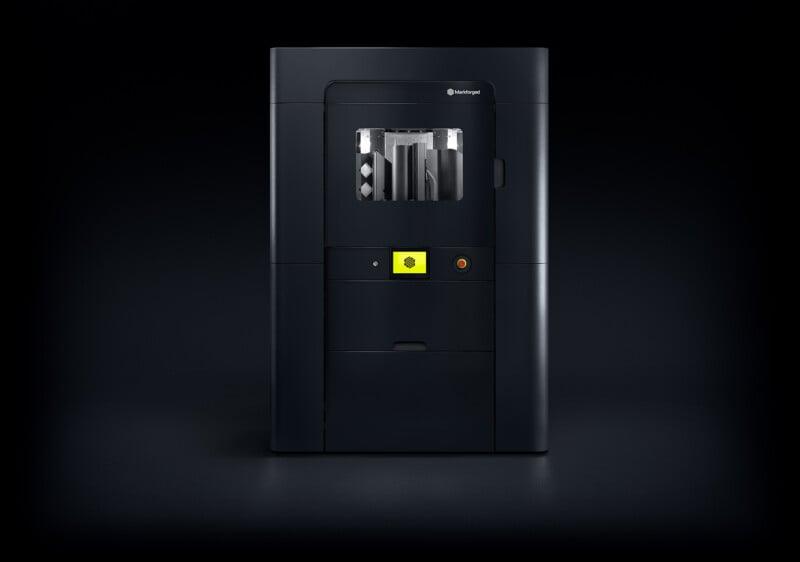

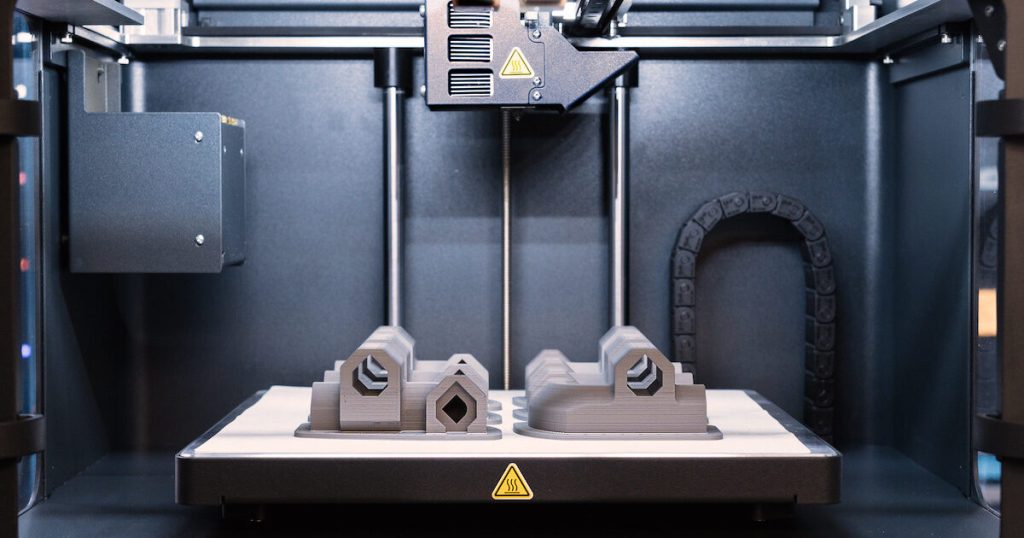

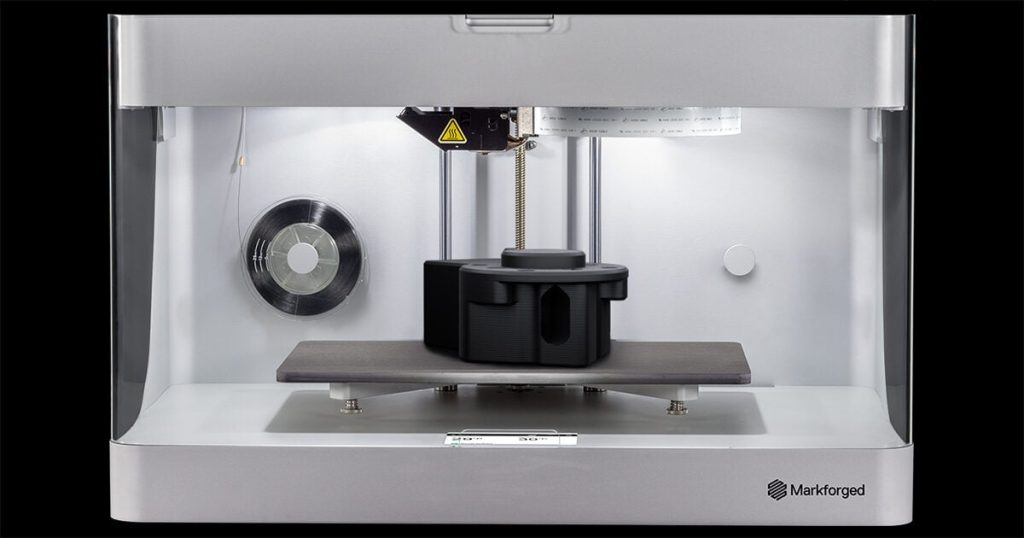

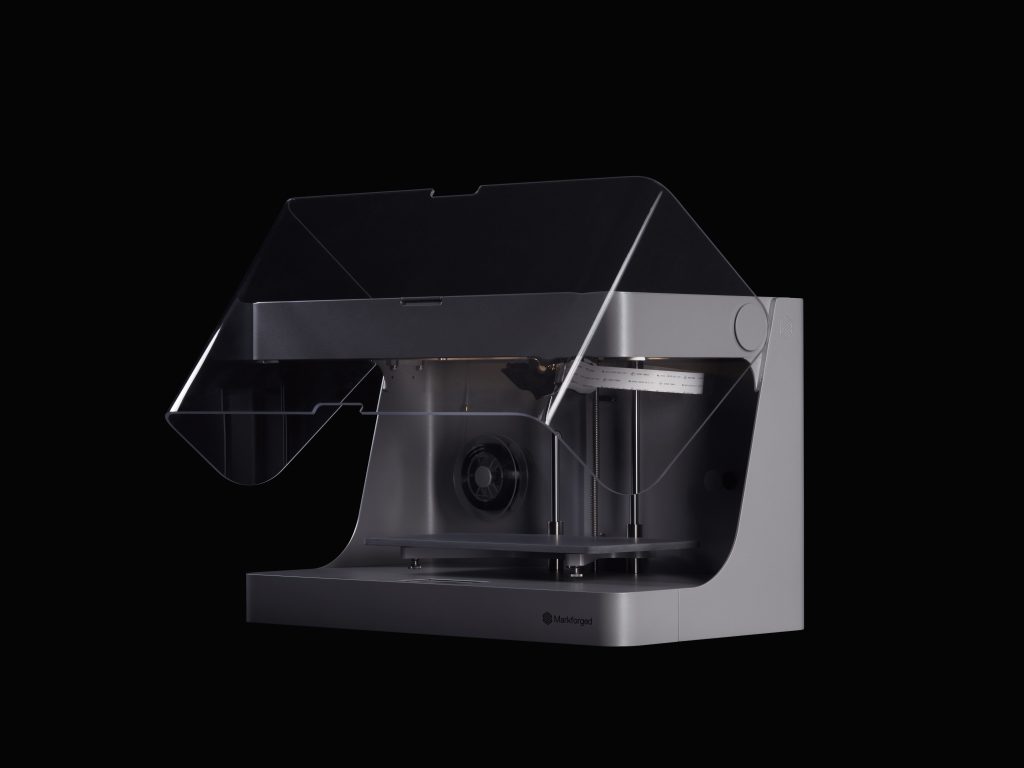

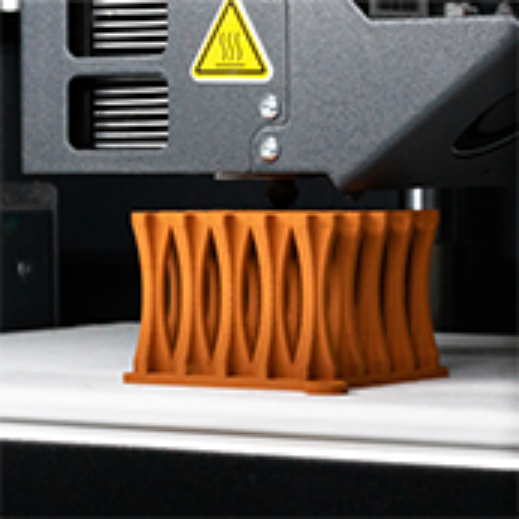

Markforged offers two distinctive high-performance ranges for composite printing with carbon fibre reinforcement capabilities. The FX20 serves organisations seeking larger production capacity with aerospace-grade materials, while the X7 targets workshops needing precision parts within space constraints. Both printers use Fused Filament Fabrication (FFF) as their base technology and reinforce builds

Comparing the Markforged FX20 and X7: Key Differences Read More »