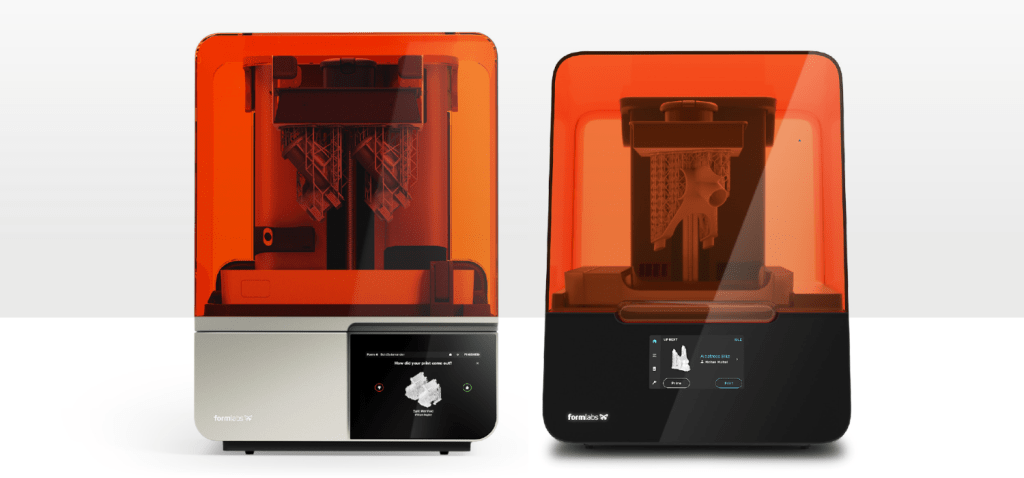

Formlabs Form 4 Post Processing: Elevate Your Productivity

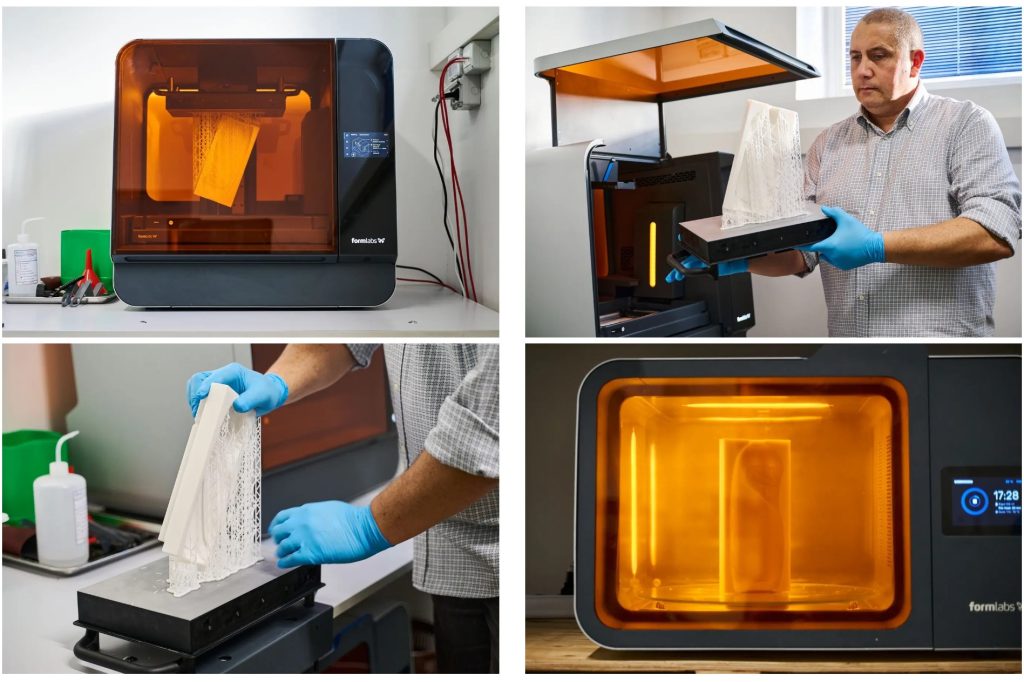

The seamless integration of Formlabs Form 4’s post-processing solutions transforms resin 3D printing from a complex, time-consuming process into an efficient, automated workflow. Combining Form Wash and Form Cure with your Form 4 printer can achieve consistently superior results while minimising hands-on time. Related shopping: Formlabs Form 4 Complete Package

Formlabs Form 4 Post Processing: Elevate Your Productivity Read More »