As a technology that has opened up new possibilities for creating complex and customized parts, 3D printing has the potential to transform the world of manufacturing. One of the most exciting developments in this field is the use of Fused Filament Fabrication (FFF), particularly metal FFF, to create 3D printed tooling. This technology has the potential to drastically improve the way we approach manufacturing, offering a more flexible, efficient, and cost-effective solution to common challenges.

Understanding Metal FFF

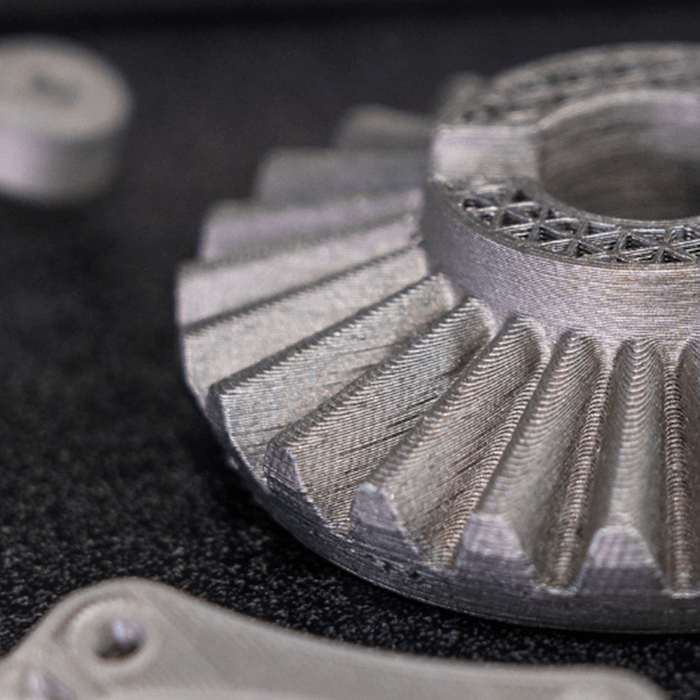

Metal FFF is a 3D printing process that uses filaments of thermoplastic material infused with metallic powder. This filament is then fed through a heated nozzle which melts the thermoplastic and allows the material to be extruded layer by layer to form objects. This process differs from other 3D printing technologies like Binder Jetting, which uses a liquid binding agent to join powder particles.

The choice of materials in metal FFF is crucial, with metal filaments playing a significant role. Companies like Markforged and Virtual Foundry have developed a range of metal filaments for FFF printers, offering manufacturers a wide choice of materials.

The quality of the metal FFF printer is also a critical factor. High-quality printers, like those produced by Ultimaker and Markforged, are designed to handle the unique challenges of metal FFF. These printers are equipped with advanced features like closed-loop motor control and direct radiative heating, which enhance the quality of the printed parts.

Furthermore, the metal FFF process involves a post-processing stage where the printed parts undergo de-binding and sintering. De-binding removes the binder, leaving behind a part composed mainly of metal. Sintering involves heating the part to a temperature below the melting point of the metal, causing the metal particles to bond together and form a solid object. This post-processing stage is crucial in achieving the desired properties and accuracy of the final part.

One of the key advantages of metal FFF is its ability to produce functional metal parts at a lower cost than conventional manufacturing techniques. This is particularly beneficial for small to medium-sized businesses, where the cost of traditional manufacturing equipment can be prohibitive. Metal FFF also offers a high degree of versatility, allowing for the creation of complex geometries that would be difficult, if not impossible, to achieve with traditional manufacturing methods. This opens up new possibilities for the design and production of 3D printed tooling.

Another significant advantage of metal FFF is the speed at which parts can be produced. Unlike traditional manufacturing methods, which often involve lengthy setup times and complex machining processes, metal FFF can produce parts quickly and efficiently. This can significantly reduce lead times, enabling manufacturers to respond more quickly to changes in demand or design modifications. Furthermore, metal FFF offers the advantage of scalability. With traditional manufacturing methods, producing a small number of parts can be expensive due to the high setup costs. However, with metal FFF, the cost per part remains relatively constant regardless of the quantity produced, making it an economical choice for both small and large production runs.

Finally, metal FFF is an environmentally friendly manufacturing method. Unlike traditional manufacturing processes, which can produce significant amounts of waste, metal FFF is an additive process, meaning material is only added where needed. This not only reduces waste but also minimizes the energy consumption associated with the manufacturing process. This eco-friendly aspect of metal FFF further enhances its appeal in today’s increasingly environmentally conscious manufacturing landscape.

Applications of Metal FFF

Metal FFF has a wide range of applications across various industries. For instance, in the automotive industry, metal FFF can be used to produce custom tooling for specific tasks, reducing the time and cost associated with traditional tooling production methods. Companies like Ultimaker and Markforged have developed metal FFF printers that are being used on the factory floor to produce parts on-demand, reducing lead times and inventory costs. These printers can also be used in the product development cycle, allowing for rapid prototyping and testing of new designs.

In the aerospace industry, metal FFF can be used used to create lightweight, high-strength components. The ability to use high-performance metals like titanium and Inconel makes metal FFF an attractive option for this industry. The medical field also benefits from metal FFF. In medicine, it can be used to create custom implants and surgical tools, thereby improving patient outcomes and surgical efficiency.

Metal FFF is becoming increasingly popular in the field of robotics, also. The ability to create complex, custom parts quickly and cost-effectively is making it an increasingly popular choice for prototyping and producing robotic components.

In the realm of education and research, metal FFF provides an accessible way for students and researchers to experiment with metal 3D printing. It allows for hands-on learning and the development of innovative solutions to engineering challenges. And, in the art and fashion industry, metal FFF is used to create intricate designs and unique pieces that would be difficult to achieve with traditional methods. This demonstrates the versatility of metal FFF and its potential to revolutionize a wide range of industries.

Exploring the Possibilities with Metal FFF

The potential of metal FFF in 3D printed tooling is vast. With the ability to produce custom, complex tools on-demand, manufacturers can significantly reduce their tooling costs and improve their production efficiency.

Moreover, with advancements in technology and materials, the capabilities of metal FFF are continually expanding. For instance, the development of new metal filaments with improved mechanical properties is opening up new possibilities for the types of tools that can be produced.

In conclusion, metal FFF represents a significant advancement in 3D printing technology, offering a versatile and cost-effective solution for producing 3D printed tooling. With companies like Ultimaker and Markforged leading the way in the development of metal FFF printers, the future of this technology looks bright. As we continue to explore the possibilities of metal FFF, there’s no doubt that this technology will play a pivotal role in the future of manufacturing.

Interested in Additive-X’s selection of metal FFF printers? Take a look at our Markforged and Ultimaker selection today. Feel free to contact us for more information.