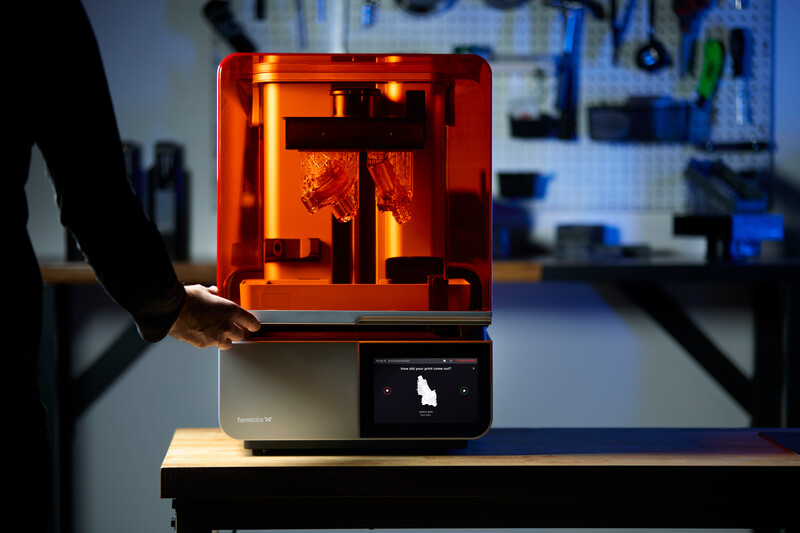

Injection moulding produces smooth builds rapidly at scale, characteristics that some 3D printers can’t match without additional equipment for vapour smoothing and sacrificing resolution (quality) for speed. But that’s about to change with the Formlabs Form 4.

The Formlabs Form 4 has a Light Processing Unit (LPU) that delivers a 50 µm XY resolution for crisp edges, well-defined planes, and smooth surfaces rivalling injection moulded plastics, and a new Low Force Display print engine, which uses a powerful combination of high-power LEDs and masking lenses to cure each layer of resin instantly.

This breakthrough technology allows the Form 4 to achieve vertical print speeds up to 100 mm per hour, outpacing professional 3D printers – including other Formlabs printers – across every technology and discipline.

But speed is just one part of the equation—the Form 4 also delivers industry-leading dimensional accuracy, with superior and repeatable tolerances that ensure printed parts match design parameters every time.

Injection-moulded quality

The Formlabs Form 4’s high-resolution printing capabilities and advanced materials, such as the updated Grey Resin V5 and Clear Resin V5, produce smooth surfaces and minimal layer lines resembling injection-moulded parts.

Injection moulding is known for its high-volume production capabilities, and the Form 4’s impressive maximum vertical print speeds of up to 100 mm per hour allow for rapid iteration and shorter lead times — particularly valuable in product development, where multiple design iterations are required before finalising a part for mass production.

Sensors for automatic resin dispensing ensure consistent performance and minimal downtime, even in high-volume production environments.

Technological advancements

The Formlabs Form 4 is faster and even more reliable than the Form 3+, with LFD (Low Force Display) delivering higher print quality and better material performance than LFS (Low Force Stereolithography) technology and traditional LCD and SLA 3D printers.

The new Low Force Display™ print engine uses a powerful combination of high-power LEDs, lens array and high resolution LCD polarising filters to deliver exceptionally controlled and collimated light uniformly across the build plane, helping maintain print accuracy and detail sharpness even at very high print speeds.

The result is a 3D printer that’s faster and more accurate than traditional SLA printers. To top it off, you also get Formlabs’ materials library.

A few materials are engineered explicitly for Formlabs Form 4, including the updated Grey Resin V5 and Clear Resin V5 and speciality resins like Flexible 80A Resin and Rigid 10K Resin – these have improved mechanical properties, surface finish, and printing performance compared to previous versions.

An automatic resin dispensing system uses intelligent sensors to maintain optimal resin levels in the tank throughout the printing process, minimising downtime and ensuring consistent print quality, even in high-volume production environments.

An integrated heating system maintains consistent resin temperature throughout printing, optimising print quality and material performance, especially for temperature-sensitive resins.

Summing up

Injection moulded parts are smooth and glossy with very tight tolerances – and that’s what you can achieve with the Formlabs Form 4.

While parts from other printers have visible layer lines and a rougher surface finish, especially with lower-resolution printers, the Form 4 can achieve smooth builds with Clear Resin V5 for transparent parts and Black Resin V5 for a completely matte surface.

The sidewalls and finer details are really smooth – you won’t believe they are 3D printed. Visit our Formlabs Form 4 product page to find out more. Any questions? Contact us.