Metal Additive Manufacturing

Markforged Metal X | 3D printing functional metal parts

Interested in a system that can yield next-day functional metal parts, without a dedicated operator, no powder management system, and minimal PPE?

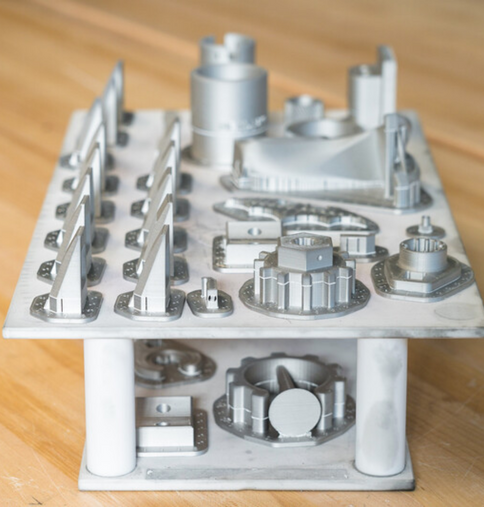

Additive-X recommends the Metal X System from Markforged: an end-to-end metal 3D printing solution capable of fabricating complex metal parts in a wide variety of metals – from stainless steel to copper. The Metal-X is purpose-built for delivering excellent part quality, whilst ensuring a seamless user experience. Design your part, upload to Markforged’s Eiger software, choose your metal, and hit print. Then you can wash your parts in the Wash-1, and sinter them in the Sinter-1 or Sinter-2.

Design | Print | Wash | Sinter | Use

What Can The Material Print?

Interested in additive manufacturing in metal?

Want to know if your application is suitable for metal 3D Printing?

Which metal is best?

Applications require prints with specific material properties. That’s why Markforged’s Metal X lets you use many different metals, with even more in development.

Copper

Thermal & electrical conductivity. Print heat-sinks, custom conductive elements & other geometrically complex parts

Stainless Steel 17-4 PH

High strength, hardness & corrosion resistance, widely used in aerospace, medium, petro-chemical. We use it for assembly fixtures & tooling

H13 Tool Steel

Hot work steel widely used in die casting, tooling and known for strength and resistance to thermal shock..

A2 Tool Steel

Cold working tool steel often used for tooling, fixtures and in mould and die shops because it provides a hard edge and is wear resistant

D2 Tool Steel

Excellent wear resistance, widely used in cold-work applications requiring compressive strength, sharp edges and abrasion resistance

Inconel 625

Superalloy which maintains mechanical properties in highly corrosive and high temperature environments

Ultrafuse® 17-4 PH

Stainless steel for high-strength (up to 880 MPa) and stiff parts (up to 190 GPa), heat and chemical resistance.

Ultrafuse® 316L

Metal-polymer composite filament for hardness and strength

Have you got a part in mind to be 3D printed in metal?

Interested in a benchmark metal print?

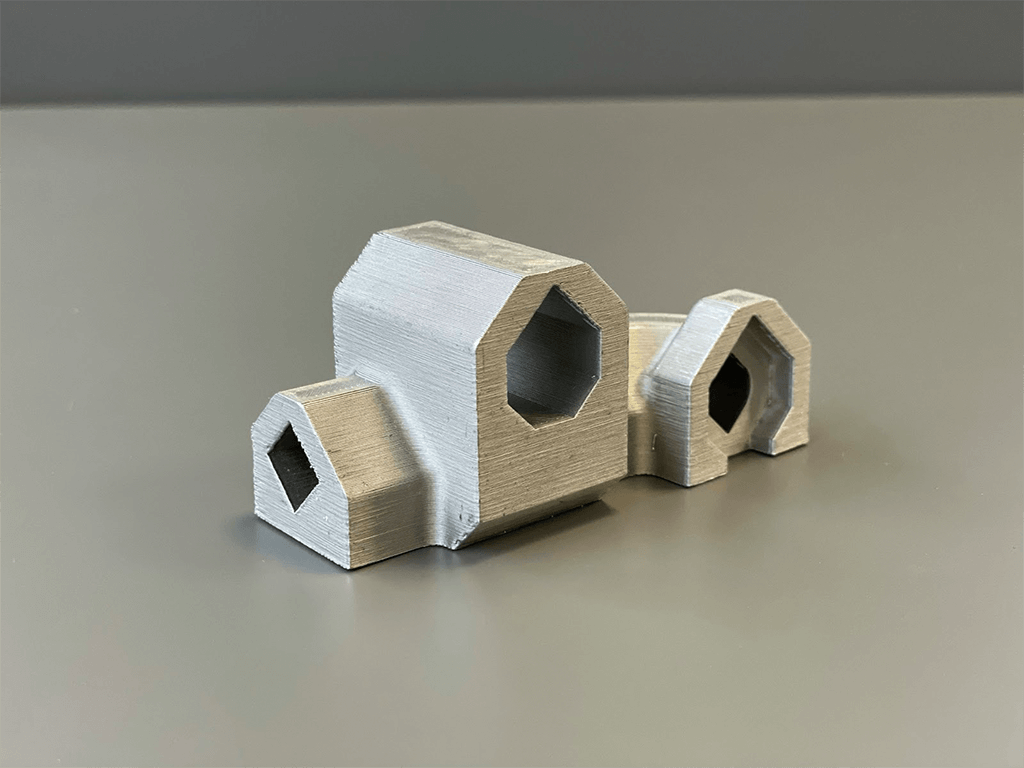

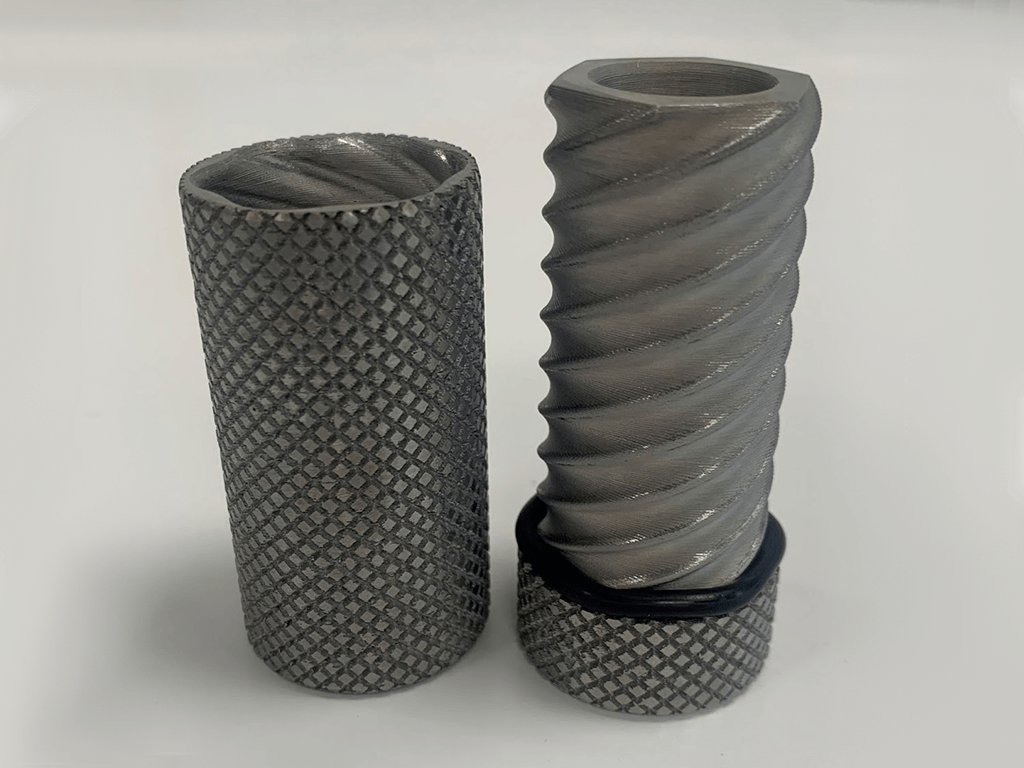

Printing Examples

Order Your Metal 3D Printing 3D Printed Parts

Get Started With 3D, Without The Investment, Make Use Of Our Custom 3D Printing Service

Printers

Additive-X | Your Experienced Additive Manufacturing Partner

30+ Years Experience • Impartial Advice & Support • ISO9001:2015 Certified

Phone, chat or talk to us at any time

FAQ’S

Commonly asked questions about Metal 3D Printing

It’s a 3 step process: print, wash, and sinter. The printing user experience is as simple as using a Markforged desktop or industrial 3D printer. The print is made from a high content metal filament. The wash is a solvent-based debinding system which is very easy to use. The ceramic release material becomes powder during the final sintering phase. The system requires minimal PPE.

A “green state part” refers to the printed part before it has undergone the washing process.

A “brown state part” is how we refer to it once it has been processed – usually washed and dried. In the brown state, the part has now had the majority of its binding material removed from the filament.

We recommend Opteon SF-79, but it is also possible to use Opteon SF-80 or Tergo Metal Cleaning Fluid.

Once suitable post-print processing has been carried out, 3D printed metal parts are comparable to their traditionally manufactured counterparts.

Between the part build and supports a layer of ceramic release material is added to help the support material snap away from the part. A ceramic release layer is also added between the part build and print raft. This means that support removal is relatively straightforward.

There is an option to print without raft in Eiger software, but we recommend using the raft as this will ensure better dimensional accuracy and precision during the sinter process.

Manual upscaling isn’t usually necessary. The Markforged Eiger system will do this for you automatically.

Yes, Markforged provide some different options: the Sinter-1, perfect for medium-sized parts and smaller batches, and the larger Sinter-2, which suits bigger parts and batch production.