Post-Processing

Part Performance

High

Post-processing can open up new applications

Ease of Use

High

Additive-X provides fully automated post-processing technologies

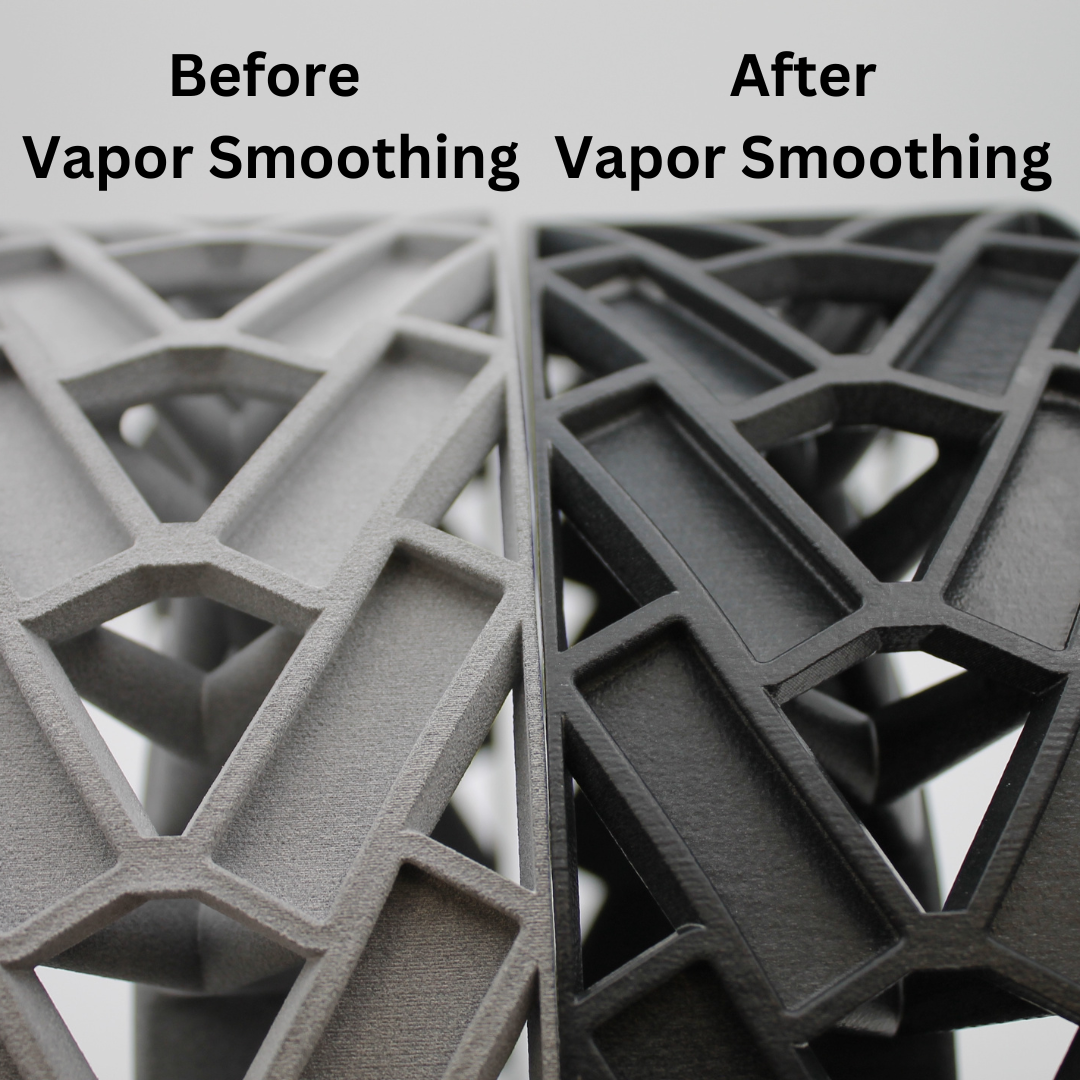

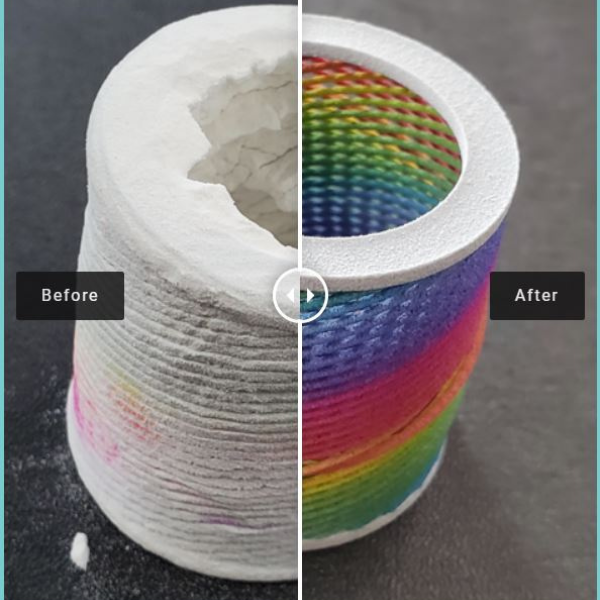

Post-processing methods can be used to make your 3D print more aesthetically pleasing as well as enhancing the material’s mechanical properties improving strength, surface finish and even making your part water or air-tight.

Additive-X offer AMT Vapor Smoothing as part of our Digital Parts Factory Service, to see the results firsthand, we are happy to provide a free-of-charge confidential benchmark of your application so you can understand the full potential of vapor smoothing

What Materials Can Be Post-Processed?

Post Processing Examples

Post-Processing Machines

AMT PostPro SF50

AMT PostPro DP Max

AMT PostPro SF100

Fully automated vapour smoothing technology that smooths and seals thermoplastic 3D printed parts

Technology: Chemical Vapour Smoothing

Process Chamber: 400 x 600 x 400 mm

Printer Compatibility: SLS, MJF, CFR, FFF/FDM, FGF, HSE and HSS

Materials Compatibility: PA6, PA11, PA12, ABS, PC, PP, TPU, TPE, SBC, PEBA, Glass/Carbon/Mineral – filled

Footprint: 830 x 1400 x 1830 mm

Cost Of Machine: Price on Request

AMT PostPro SFX

The World's First Bench-Top Chemical Vapour Smoothing System!

Technology: Chemical Vapour Smoothing

Power Chamber Volume: 11.5 Litres

Printer Compatibility: SLS, MJF, CFR, FFF/FDM, FGF, HSE and HSS

Footprint: 450 x 500 x 845 mm

Cost Of Machine: Price on Request

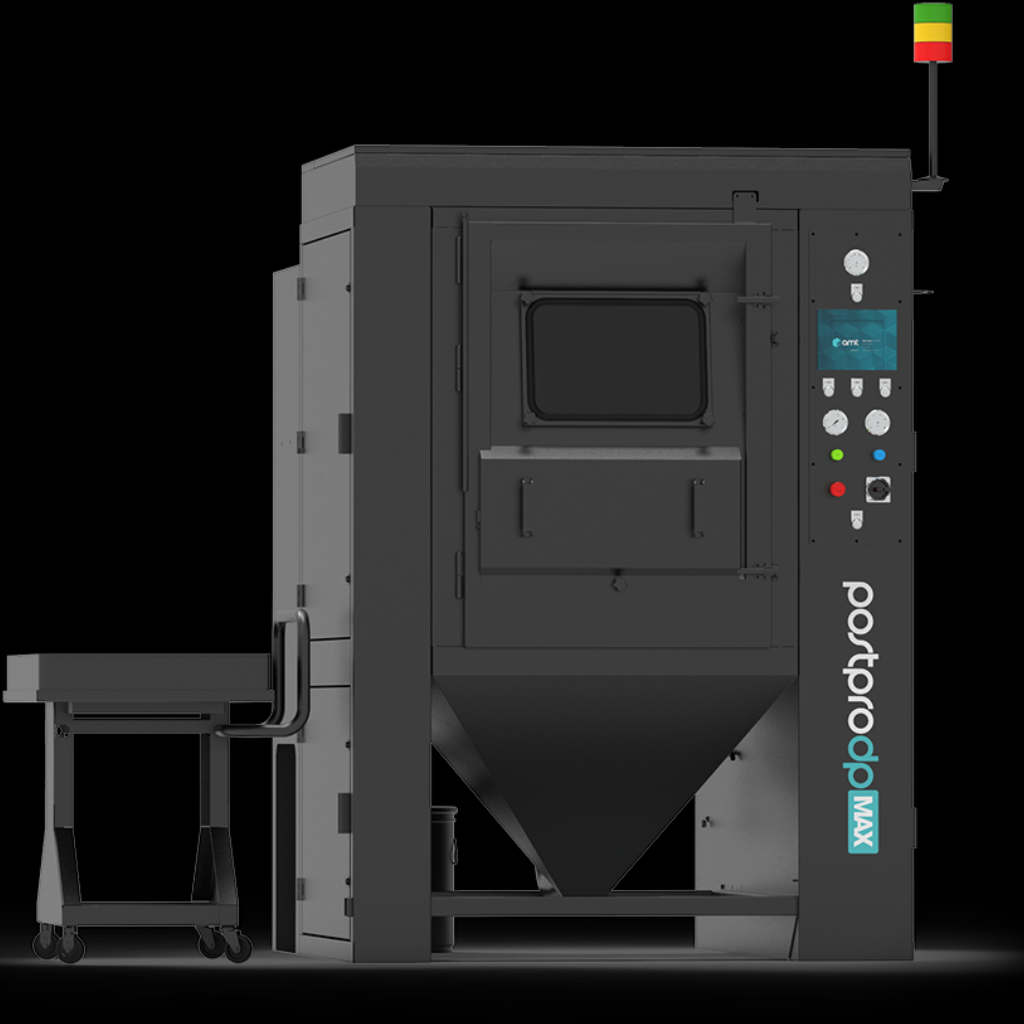

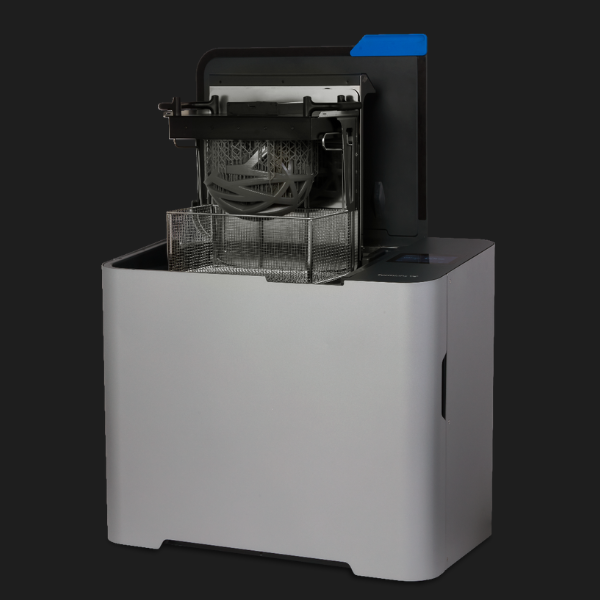

AMT PostPro DP Max

Fully automated, affordable 2 in 1 de-powdering and shot blast cleaning system for maximum throughput, includes 3 blast guns

Max Load: 30 kg

Printer Compatibility: SLS, MJF, CFR, FFF/FDM, FGF, HSE, HSS

Blast Media: Glass beads, polybeads, corundum, ceramics, nut shells, plastics, fine sized stainless steel and steel

Footprint: 1,617 x 1,760 x 2,506 mm

Cost Of Machine: Price on Request

Formlabs Fuse Sift

All in one powder recovery for the Fuse series

Technology: SLS

Fuse Build Dimensions: 16.5 x 16.5 x 30 cm

Materials Compatibility: Nylon 12, Nylon 12 GF and Nylon 11 and Nylon 11 CF

Printer Compatibility: Formlabs Fuse 1+ 30W and Formlabs Fuse 1

Cost Of Machine: Starting at £7,699

UltiMaker PVA Removal Station

Simple post-processing. Faster parts

Technology: FFF

Maximum Part Size: 200 x 230 x 165 mm

Operating Temperature: 15 – 32°C

Materials Available: PVA and PLA

Opensource: No

Cost Of Machine: Starting at £780

Formlabs Form Wash

For automated cleaning of parts printed on your Form 3+, Form 3B+, Form 2

Technology: Washing with IPA, TPM or Water

Bucket Volume: 8.6 litres

Maximum Part Size 14.5 x 14.5 x 17.5 cm

Approx Wash Time: 15 minutes with fresh isopropyl alcohol (IPA)

Prints per IPA refill: Approx 70 in regular use

Cost Of Machine: £510

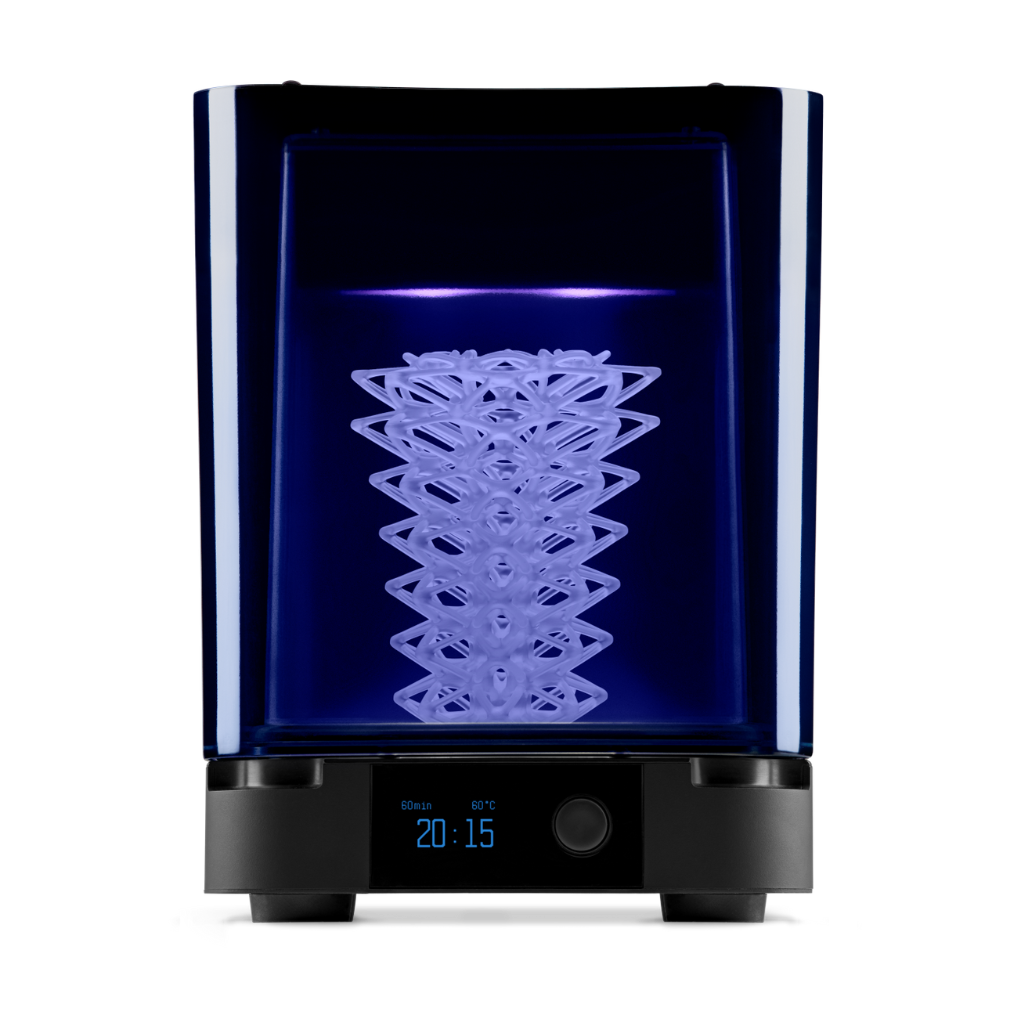

Formlabs Form Cure

High-Intensity, Fast Post-curing for 3D printed parts from your Form 3+, Form 3B+, Form 2

Technology: LED-light curing with 13 multi-directional LEDs

Maximum Part Size: 14.5 × 14.5 × 17.5 cm

Heat: Precise heat control up to 80 c

Cost Of Machine: £640

Formlabs Form Cure L

High-Intensity, Fast Post-curing for 3D printed parts from your Formlabs SLA Printers

Maximum Part Height: 32cm

Dimensions: 69 × 54 × 44.5 cm

Operating Temperature: Suggested 18-28°C

Cost Of Machine: £2,990

Formlabs Form Wash L

For automated cleaning of printed SLA parts

Bucket Volume: 37.9L

Maximum Part Size: 33.5 × 20 × 30 cm

Weight: 56.7 KG

Cost Of Machine: £3,410

Formlabs Fuse Blast

Reinventing SLS Post-Processing with a fully automated cleaning and polishing solution in minutes.

Bucket Volume: 37.9L

Dimensions: 100 × 75 × 175 cm

Weight (without media): 164 KG

Cost Of Machine: £9,199

User Stories

Additive-X | Your experienced additive manufacturing partner

Impartial Advice & Support • Printing service • Stock for next-day delivery

Whether you need answers, benchmark prints or a quote with the latest special offer, Additive-X are here to help you

FAQ’S

Commonly asked questions about Post-Processing

It smooths and seals the surface of the 3D printed parts achieving an injection molded look and feel. In addition the process allows you to smooth complex geometries and internal cavities of thermoplastic parts without degrading the mechanical properties.

For best results, Formlabs recommends washing printed parts in isopropyl alcohol (IPA) or tripropylene gycol monomethyl ether (TPM)

Agitating parts in IPA using Formlabs Finish Kits or automated Form Wash stations

Some of our functional resins require post curing to achieve their optimal mechanical properties, but the standard resins do not.