The New Build Platform 2L: 3D Printing Just Got Even Easier

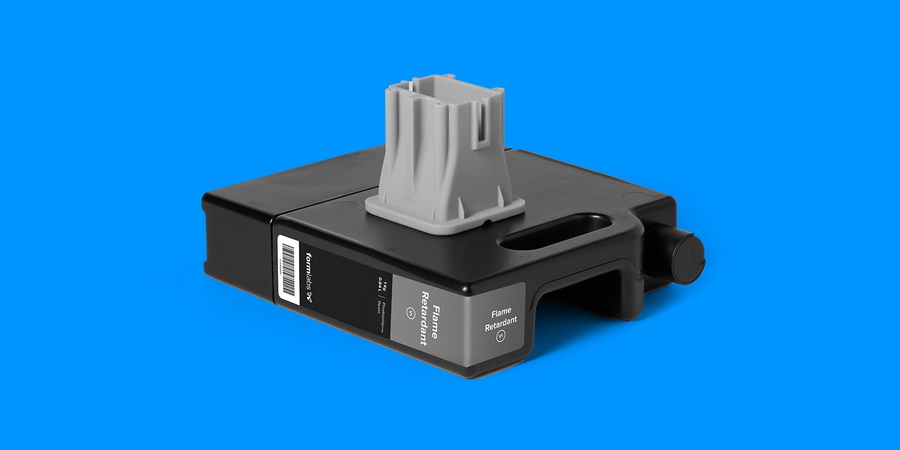

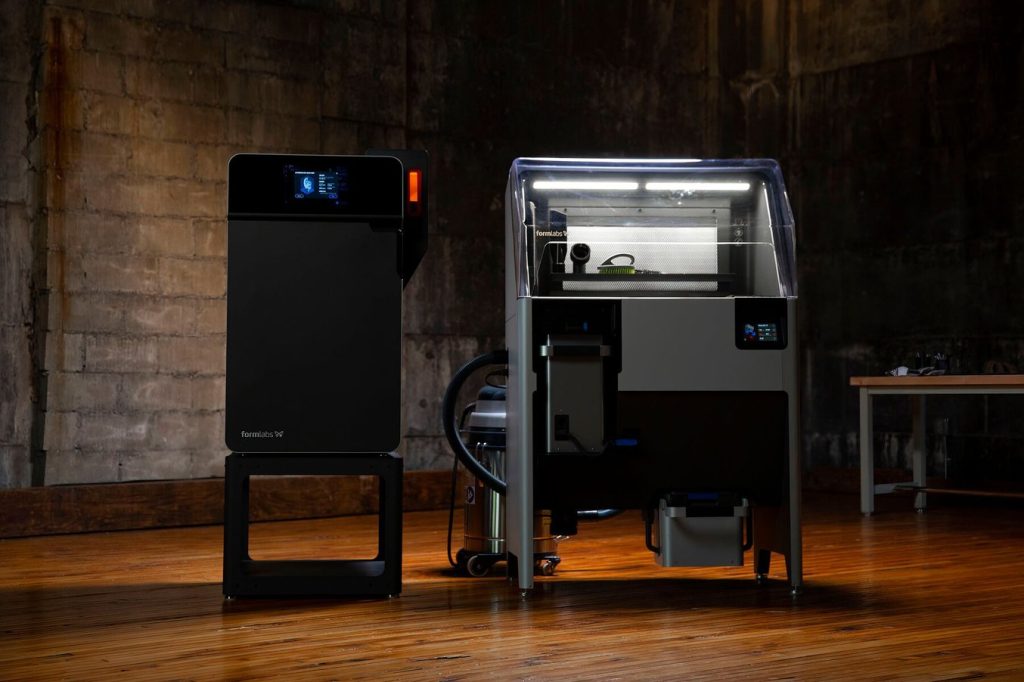

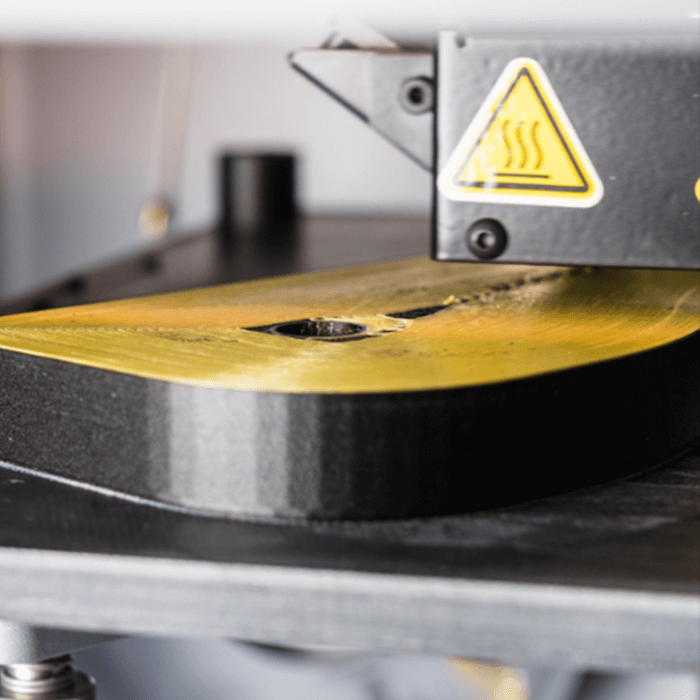

The Formlabs Form 3L and Form 3BL boast feature sets that are revolutionising post-processing for benchtop SLA printing, and with the addition of the Build Platform 2L, the workflow is revolutionised even further. Using cutting-edge Quick Release Technology, it streamlines post-processing for benchtop SLA and enables 24/7 operations when used

The New Build Platform 2L: 3D Printing Just Got Even Easier Read More »