Without the artistry of prop masters, some of Hollywood’s most memorable films, like Guardians of the Galaxy, Star Wars, and Back to the Future, would lack the dazzling visual effects that make them so iconic.

Prop-making takes skill, imagination, and creativity, all under the constant pressure of deadlines and resource constraints. Thankfully, 3D printing props means prop makers are having something of a reprieve thanks to additive manufacturing.

AM is an everyday tool that can expedite prop-making while encouraging creativity, allowing for a smoother and more efficient design process.

AM and prop making

For 3D printing to work for the film industry, it requires three things:

- The quality and detail must meet or exceed that of traditional techniques.

- The 3D printer must be able to produce items of sufficient sizes, such as a human head, torso, or helmet.

- The 3D printer must be cost-effective, efficient, and dependable, as deadlines and finances are usually very tight.

An SLA (stereolithography) 3D printer with a large build volume is the best choice for detailed 3D printing props due to the technology’s ability to create intricate details and small features.

SLA 3D printers like the Formlabs Form 3+ and Form 3L use a laser to cure liquid resin onto a build platform in layers, producing isotropic models.

SLA is perfect for dimensional accuracy, a smooth surface finish, and small features. Formlabs printers have the advantage of proprietary Low Force Stereolithography, which enhances print quality with a smooth surface finish, and creates light-touch supports that snap away cleanly from models.

Grey Resin, Clear Resin, White Resin, and Black Resin are perfect for prop-making because they offer balanced print speed, quality and cost. Durable Resin and Tough Resin offer great performance for functional props and prototypes.

How AM is changing the prop-making game

3D printers can replace many traditional prop-making techniques, such as silicone life casting, and can build previously impossible shapes with a digital workflow that saves time, effort, and money.

For example, Russel Bobbitt is a prop master at Marvel Studios with three decades of experience designing props for films such as Iron Man. He uses 3D printing props to produce intricate and true-to-design props, working with illustrators and artists to create props and models that look good and perform well.

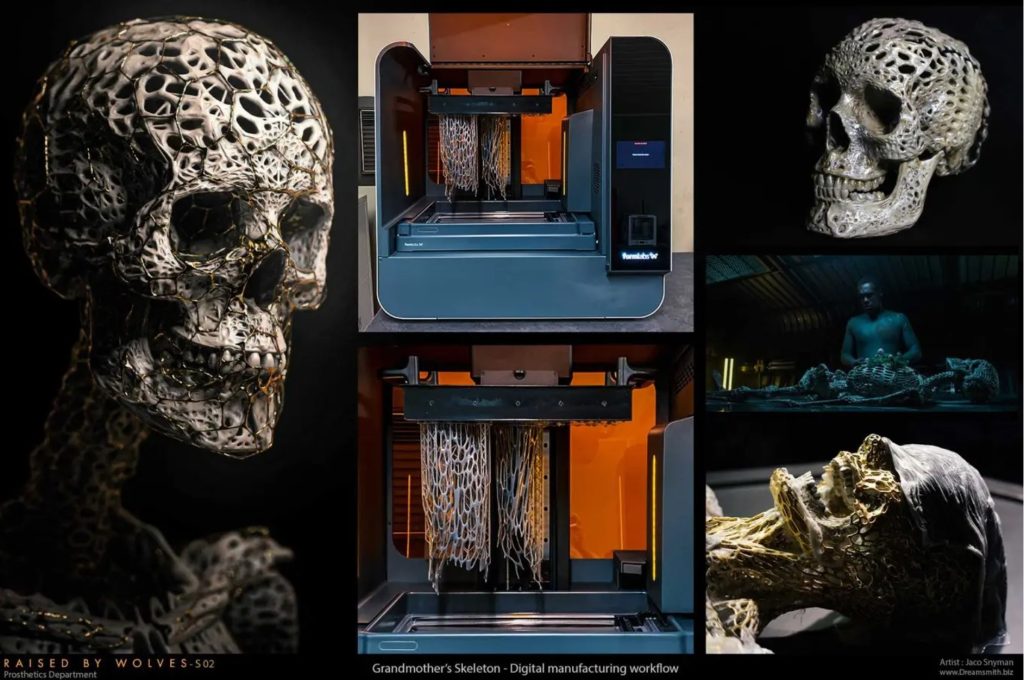

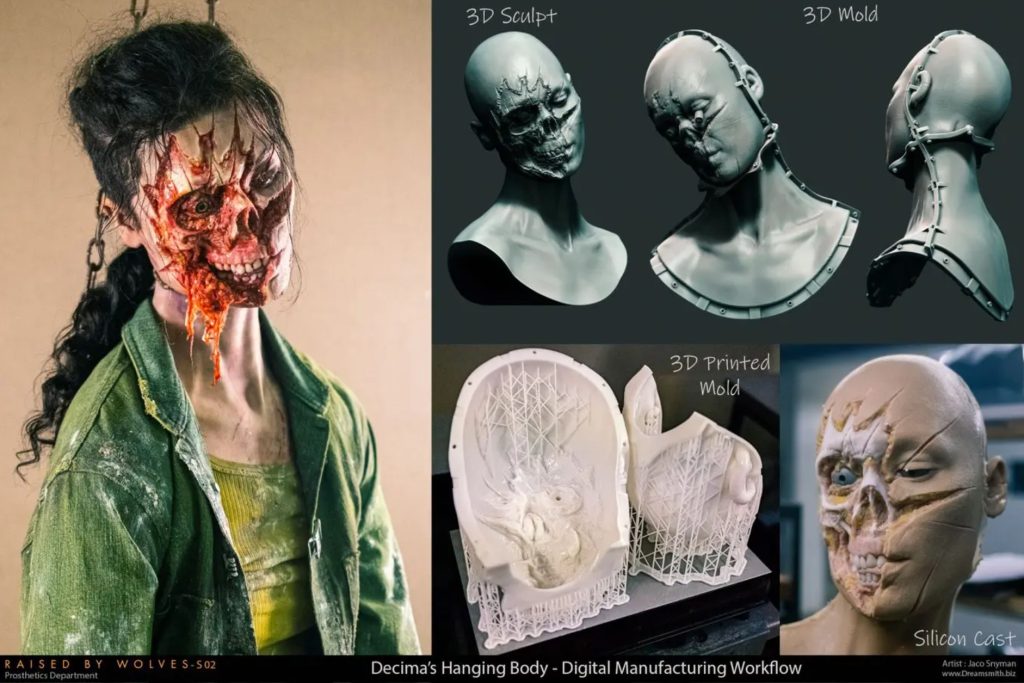

Another example is the use of the Formlabs Form 3L to create a final mould of the head of an actress for Raised by Wolves Season 2. 3D printing props eliminated the need for life-casting, and the entire workflow only required one person.

Using their experience with the Form 3L 3D printer and experimenting with multiple materials from the Formlabs resin library, the Raised by Wolves team developed a revolutionary process for prosthetic makeup application.

Starting with a 3D scan of the actor, they digitally sculpt the prosthetic makeup and then use a hybrid silicon casting technique with a thin layer of silicone sandwiched between a 3D printed mould shell and a 3D printed base.

AM’s digital workflow and designing with CAD can also be of great benefit to production deadlines and costs. Previously, if the brief could not be completed by hand or was too time-consuming and impractical, outsourcing the job to a machine shop or passing the job on entirely was often the only option.

Now, advancements in 3D printing make it possible for designers to produce entire props and parts in-house without the need for expensive outsourcing.

The creative process

AM requires only one operator, and there’s no tooling required. It cuts lead times, and it reduces waste and costs. Props that would take weeks or months to build are printable in days. But is the creative process simple?

The short answer is yes, and it is also inspiring new prop-making workflows.

Here’s what the digital workflow of AM looks like:

- Modelling in CAD: This involves designing a prop in a computer-aided design (CAD) program, such as Fusion 360. This is the most time-intensive step for prop masters.

- Generating an STL or 3MF File: Next you convert the CAD model into a 3D format compatible with the 3D printer.

- Slicing: Next you use slicing software to convert the 3D file into instructions for the 3D printer.

- Printing: The sliced model is then sent to a 3D printer, which prints the model one layer at a time until the build is complete.

- Post-Processing: After printing, the prop may require some post-processing, such as removing any remaining supports or smoothing out any rough edges. Once the post-processing is complete, the model is ready for use.

Nothing here isn’t learnable, and as 3D printing replaces traditional prop-making techniques, new opportunities are opening for prop makers everywhere.

AM allows for creativity and impressive prop making results in far less time and cost, making it one of the most valuable tools in the film industry.

Find out more

To find out more about 3D printing for prop making, chat with our team on 01765 694 007 or email [email protected].

Top image credit: Formlabs.