TPU 90A Powder for the Formlabs Fuse Series lets you produce advanced, flexible elastomeric parts in-house.

Thermoplastic Polyurethane is a remarkably elastic, resilient, and durable material that withstands wear and tear, oils, solvents, and greases. Its soft-touch properties also make it a practical choice for consumer products.

The Fuse Series is a user-friendly, cost-effective Formlabs SLS 3D printing system tailored to quickly and precisely create TPU parts. It is the ideal solution for producing rubberised parts, rapid prototyping, and custom manufacturing.

With this powder bed fusion system, you can gain momentum in your production, decentralise your manufacturing methods, and stabilise your supply chains.

Formlabs SLS pushes the boundaries of fabrication, enabling new workflows by continuously expanding its powder library with new materials like TPU 90A Powder, making it easier than ever to produce complex, industrial-grade parts and models.

What is TPU 90A?

TPU 90A is a highly versatile elastomeric thermoplastic for engineering, design, and manufacturing applications. It is known for its durability, making it an excellent choice for long-lasting, rubberised components.

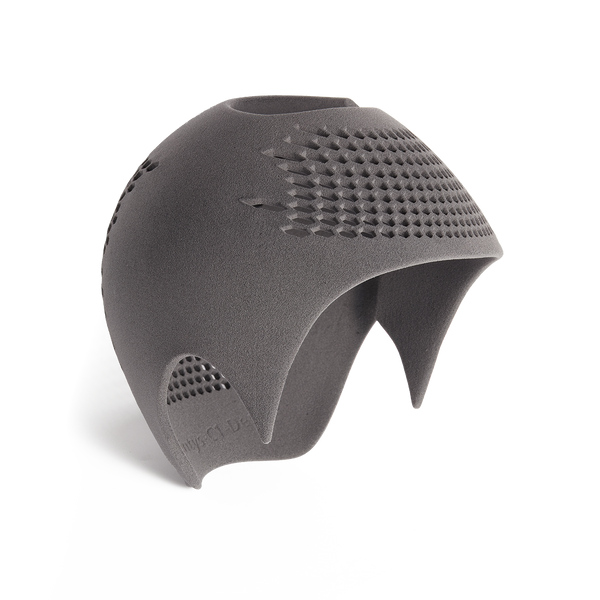

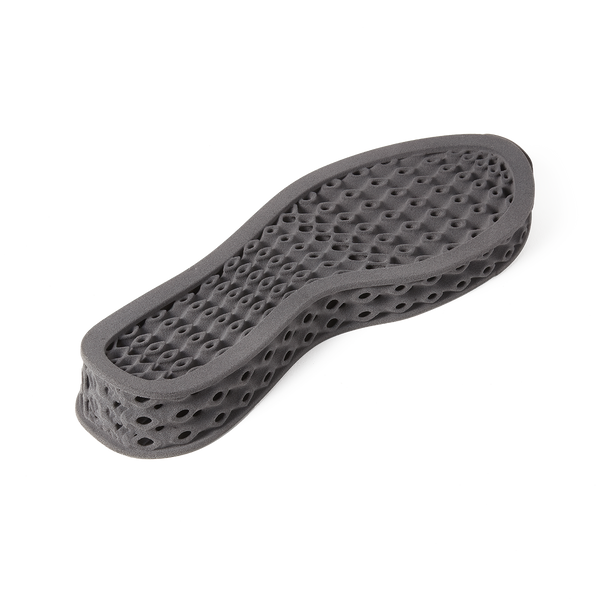

TPU 90A Powder provides unmatched design freedom for creating flexible parts, offering a balance of high elongation at break and superior tear strength – ideal for skin-safe prototypes and long-wearing end-use parts.

It has a low cost per part due to its 20% refresh rate (meaning you can use up to 80% reclaimed powder with the Fuse 1+ 30W). It demonstrates an outstanding 310% elongation-at-break on the X/Y axis, making it highly tear-resistant and incredibly ductile.

Other material properties include a 66 k/Nm tear strength (X/Y) and a 94.3°C Vicat Softening Temperature. The datasheet offers complete material properties.

Good durability and excellent abrasion resistance make TPU 90A ideal for prototyping and end-use applications, including:

- Padding and vibration dampers.

- Grippers and covers.

- Gaskets, seals, belts, and tubes.

- Protective casings.

- Soles, splints, orthotics, and prosthetics.

- Wearables like masks and goggle housings.

Printing TPU 90A with the Fuse series offers an easy-to-use workflow for rapid prototyping and on-demand manufacturing.

This technology is particularly suited to the automotive, aerospace, engineering, and medical industries because it can quickly produce highly complex parts.

What is SLS?

Formlabs SLS 3D printers employ a high-powered laser to precisely sinter layers of powder particles into the desired 3D form. The laser traces the cross-section of a 3D model, creating a thin layer of these particles in its shape. More layers of particles are then spread across the build chamber and sintered until the model is complete.

This process is strikingly different to FFF 3D printers, which deposit a melted thermoplastic onto a build plate layer-by-layer with an extruder, and SLA printers, which use a laser to cure liquid resin onto the build platform.

SLS offers distinct advantages over FFF and SLA, such as eliminating support structures for overhanging features, internal channels, and interlocking parts.

No requirement for support materials makes post-processing easier, faster, and more efficient, leading to faster production times.

How are no supports required? Because unfused powder supports the part during printing, enabling complex and interconnected models free from support structures.

Formlabs SLS parts can also be printed hollow to save weight with escape holes to remove unfused powder from enclosed or deep cavities, enabling the production of super-lightweight parts.

You can also nest parts by optimising part orientation to reduce wasted print volume, enabling multiple models to be built in one print run.

SLS produces high part strength and dimensional accuracy due to the powder sintering together. Parts are dense with high isotropy, exhibiting property uniformity.

The Formlabs Fuse Series delivers these advantages with the Fuse 1+ 30W, priced to allow small and medium manufacturers to bring Formlabs SLS in-house more affordably than the industrial machines that dominate the factory floor.

The Fuse 1+ 30W can print Nylon 12, Nylon 12 GF, Nylon 11, and Nylon 11 CF, which are semi-rigid materials. The newest material in the catalogue, TPU 90A, is the first flexible and rubbery material in the Formlabs SLS material catalogue.

Introducing the Fuse 1+ 30W

The Fuse 1+ 30W is Formlabs’ newest SLS 3D printer, released in 2022 as the successor to the Fuse 1 3D printer released in 2021.

The Fuse 1+ 30W laser has revolutionary improvements compared to its predecessor. It boasts a 30W laser, enhanced scanning speeds up to 12.5 meters per second and a drastically reduced waste generation. These features contribute to a faster printing time – up to twice the speed of the previous model.

With the upgraded packing algorithm, you can design multiple versions and print them on the same day, making iterative prototyping more efficient.

Specialised products and small, intricate components are increasingly the focus of designers or design teams, so using the improved packing algorithm can help move the process forward quickly and easily.

With the Fuse 1+ 30W, the cost per part is not prohibitive, while turnaround times and workflows are streamlined and optimised. With this affordable entry-point option, the cost of the printer can be recouped in a few months– much sooner than many businesses’ old outsourcing costs. Lower refresh rates mean a lower ongoing cost for consumables, resulting in a faster return on investment for the printer.

Here are the system specifications:

- Dimensions: 68.5 x 64.5 x 106.5 cm (27 x 25.4 x 41.9 in).

- Build volume: 165 × 165 × 300 mm (6.5 x 6.5 x11.8 in).

- Layer thickness: 110 microns (0.004 in).

- Laser: Ytterbium Fiber 30W.

- Laser spot size: 247 microns (0.0097 in).

- Heated chamber temp: Up to 200 ºC (392 ºF).

- File formats: STL, OBJ, FORM file output.

- Interface: Touchscreen at point-of-use, cloud software.

Find out more

To find out more about Formlabs SLS, flexible materials and the Formlabs 3D printer range, call us on 01765 694 007 or email [email protected].

Image credits: Formlabs.