Metal additive manufacturing can replace traditional manufacturing techniques like machining, drawing, and casting with a digital workflow that enables the production of previously impossible geometries and detail.

Where metal 3D printing really comes into its own is when working with tight tolerances, irregular shapes, thin walls and hollows, and internal structures. It can even produce large metal components in one go to replace smaller assemblies.

Getting started with metal 3D printing

The most cost-effective entry point into metal additive manufacturing is Fused Filament Fabrication (FFF) technology, which deposits a plastic-bound metal filament through a nozzle onto a build plate in layers until the build is complete.

After printing, green parts (freshly printed but incomplete parts) require debinding and sintering to turn into solid metal.

Debinding breaks down the plastic binder while sintering heats the part in a furnace to burn away the remaining binder and melt and fuse layers together with the resulting parts solid and ready to use.

Metal FFF parts also have support structures made from metal, separated from the build by a ceramic release material. Supports are removed after sintering.

Parts can be post-processed further after sintering, including sanding/polishing and machining for extremely tight tolerances. Additionally, you can heat-treat parts to improve strength, stiffness, elongation, and hardness.

There are two ecosystems we recommend for this: Markforged and BCN3D.

Markforged Metal X

The Markforged Metal X with the Wash 1 and Sinter 2 is a complete FFF metal 3D printing ecosystem, giving you the 3D printer, wash station, and furnace to produce complete metal components for end use.

The Metal X also offers an unbeatable range of metals:

- 17-4PH Stainless Steel

- Copper

- H13 Tool Steel

- Inconel 625

- A2 and D2 Tool Steel

With the Metal X, you also benefit from Eiger, a cloud-based slicing system that can simulate real-world conditions to virtually test and validate parts.

The Metal X excels for low-volume, custom parts like heat sinks and is the perfect digital workflow solution for forming, cutting, and bonding, where it can produce steel dies, cutting tools, shanks, induction coils, and more.

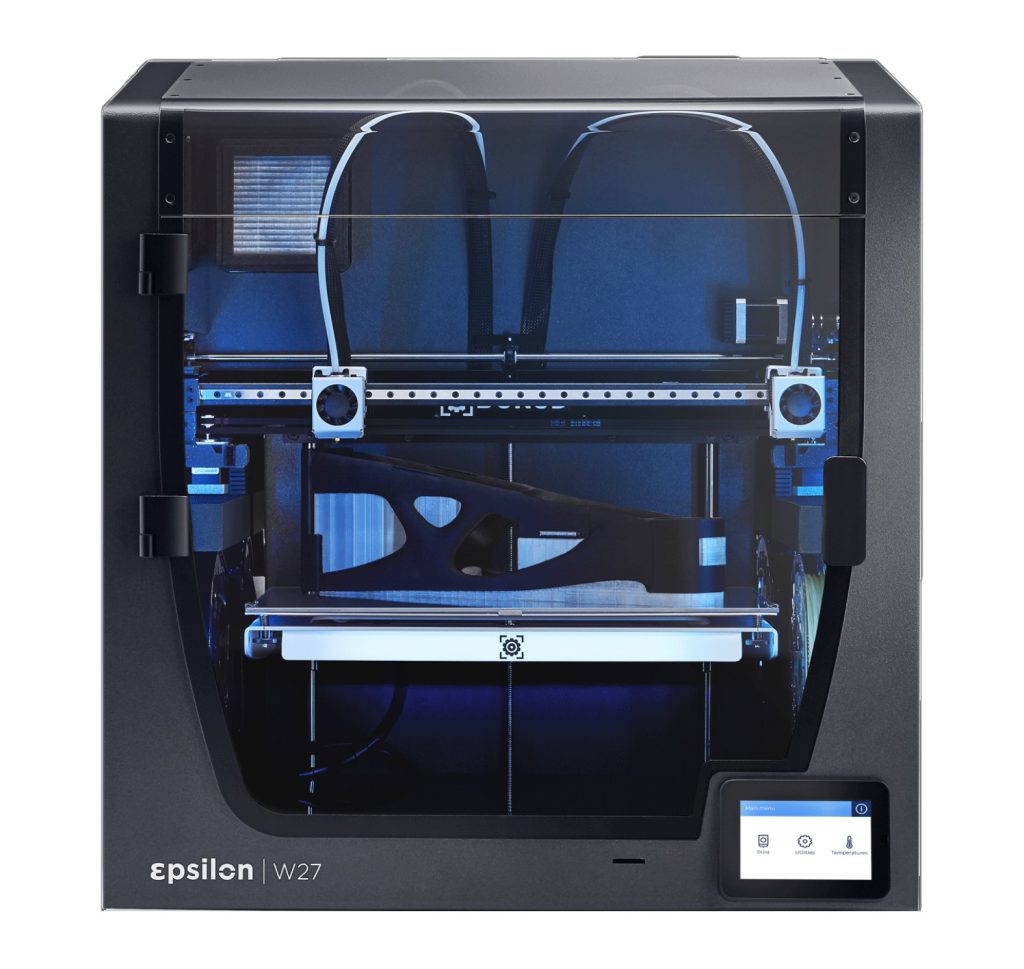

BCN3D Epsilon Series with the Metal Pack

Another option is the BCN3D Epsilon Series, including the Epsilon W50 and W50 SC, Epsilon W27 and W27 SC. These 3D printers are compatible with the BCN3D Metal Pack, letting you print 316L and 17-4 PH stainless steel.

The BCN3D Metal Pack is tailored to provide a smooth 3D printing experience with metal parts. It includes Ultrafuse® 316L and 17-4 PH filaments and a new, exclusive hot end designed specifically for metal printing.

The BCN3D Stratos slicer has a metal printing profile that reduces internal tensions during printing. After printing, you can submit to external services for debinding and sintering with Forward AM authorised suppliers (alternatively, you can de-bind and sinter components in-house).

Although the material support is lower than Markforged’s, 316L and 17-4 PH steel offer hundreds of applications for jigs and fixtures, tooling, and functional prototypes, with the Epsilon Series boasting outstanding precision.

Closing thoughts

Metal additive manufacturing opens endless possibilities in the design-to-manufacturing loop, bringing the power to quickly iterate and prototype to the metal world while taking production to the next level.

FFF metal 3D printing can expand your build potential in size, quality, and price. With the Markforged Metal X, you can print end-use parts with high degrees of strength and detail, while the BCN3D Metal Pack lets you prototype and produce functional parts with great accuracy and repeatability.

Find out more

To find out more and to get started with metal additive manufacturing, call us on 01765 694 007 or email [email protected].