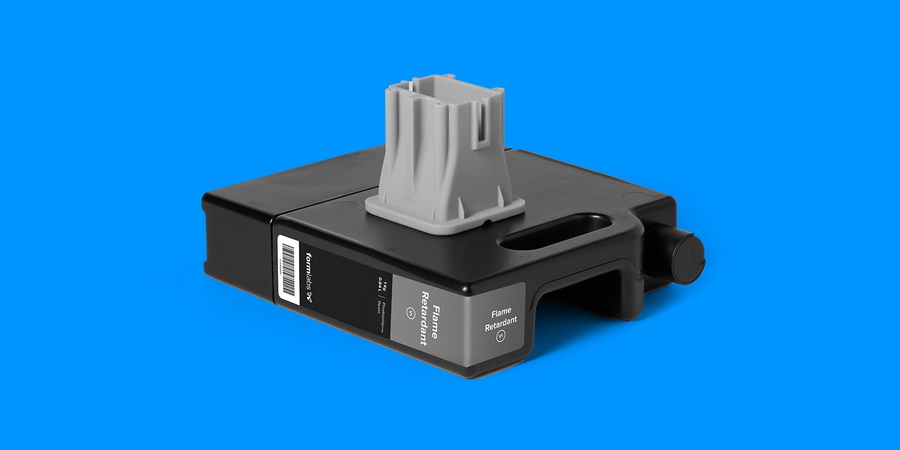

Formlabs has launched Flame Retardant Resin, a self-extinguishing, UL 94 V-0 certified material for stereolithography 3D printing.

Perfect for multiple industries, including transportation, aviation, manufacturing and medical, this regulator-approved resin provides users with the speed, design freedom and safety that high-stakes applications demand.

Flame Retardant Resin will transform how automotive, aerospace, and manufacturing industries create parts for prototyping, maintenance and repair, and manufacturing fixtures.

Why Flame Retardant Resin?

UL 94 is the gold standard for plastics flammability certification, which measures how a material reacts when ignited.

To meet these strict requirements, Formlabs Flame Retardant Resin is UL 94 V-0 Blue Card certified, successfully passing FAR 25.853(a) flame standards and smoke and toxicity tests to endure the temperature and open-flame environment of hazardous areas.

To acquire components with the required UL 94 rating, many companies turn to machine shops or moulding operations. However, they frequently experience lengthy lead times or expensive expedition fees.

In–house processes such as silicone and polyurethane casting, with the use of either machined or 3D–printed patterns, can be a more budget–friendly solution, though may require a longer period of time to complete.

FFF 3D printer manufacturers also offer flame retardant filaments, but these parts are often unsuitable for functional testing, end-use purposes, or maintenance and repair. SLA 3D printing materials offer isotropic strength and a high-quality surface finish, but the lack of UL 94 certification has been a major deterrent. This limitation is now over with FR Resin.

New production capabilities

Flame Retardant Resin is perfect for quickly turning concepts into tangible products and small– to medium–scale production runs.

Utilising the Formlabs Form 3+ or Form 3L and Flame Retardant Resin allows users to streamline their workflow, making it much easier to transition from the iterative design phase to end-use parts.

Using the same Flame Retardant Resin in manufacturing allows you to avoid the time and resources associated with refitting and ensures the components are compliant with legal regulations.

This enables you to accelerate your product launch, with strong and dependable parts.

For example, NZ Technologies (NZTech) used their Form 3+ 3D printer to streamline their design process for their TIPSO® AirPad product, a touchless interface for surgeons.

The Form 3+ was ideal for the advanced human-machine interaction (HMI) product due to its resolution and on-demand power. With the addition of Flame-Retardant Resin, NZTech made parts with the same materials as the final product, ensuring easy mesh and dimensional accuracy for testing and certification.

Find out more

3D printing has revolutionised the design process within safety-first, strictly regulated industries by unlocking the capacity for enhanced geometric complexity while facilitating innovation.

Formlabs’ Flame Retardant Resin furthers this by making it simpler for smaller companies to churn out prototypes and generate in-lab testing, while encouraging sizeable businesses to quickly and competently manufacture short-run items.

Its ability to safely pass the UL rating and match the strength and heat deflection temperatures previously achievable through traditional manufacturing methods allows you to drastically improve your development timelines and slash outsourcing costs.

To find out more and to get started with SLA and Flame Retardant Resin, call us on 01765 694 007 or email [email protected].