Titanium is a highly valued material in engineering, high-performance product fabrication, and medical applications due to its biocompatibility and superior strength-to-weight ratio. It produces parts 3 to 4 times stronger than stainless steel with a higher melting point.

Titanium’s high mechanical strength and corrosion resistance have led the aerospace industry to approve various 3D printed titanium parts for commercial and military use, such as aircraft airframes, blades, housings, castings, and other highly-loaded components and structures.

The downside to 3D printing titanium is it is expensive in the short term, irrespective of the part size or quantity, leading many firms to outsource the fabrication of titanium components, or machine simpler parts that are less suitable for the job.

The big question is whether titanium is worth the investment cost in the long term, and the answer depends on your intended applications and industry.

When titanium is necessary

Titanium is necessary for applications when other engineering materials like 17-4 PH stainless steel have unsuitable properties.

There are several cases where this is relevant:

Biocompatible metal parts

3D printing is revolutionising the medical implant market by allowing for mass customisation to better meet individual patients’ needs.

With their inherent biocompatibility and good mechanical properties, titanium implants are finding a wide range of successful applications in spine, hip, knee, and extremity surgeries, with additive manufacturing’s ability to create porous structures enabling bone integration.

Lightweight, high-strength parts

Titanium’s high strength-to-weight ratio makes it a favourable choice in the aerospace and automotive industries, where lightweight yet strong materials are at a premium to enhance performance, safety, and fuel economy.

Titanium parts allow for minimal weight and volume compared to products made with other metals, making them easier to manoeuvre, transport and store. In addition, their low thermal expansion facilitates optimal heat resistance.

High-temperature parts

Titanium alloys are well-suited for components subjected to extreme temperatures, offering high absolute and high-density specific strength. Titanium parts exhibit excellent corrosion resistance at low and high temperatures, allowing components to stay consistent and reliable when exposed to extreme conditions.

The fatigue performance of titanium alloys at high temperatures is impressive. It demonstrates a significantly higher fatigue strength than many other metals and alloys, ideal for components that will see repetitive use.

Know your titanium

Titanium Ti-6Al-4V is printed by the Markforged PX100, prized for precision manufacturing, biocompatible medical devices, the aerospace and automotive industries, military applications, and other areas where complex geometries and precision components are required, such as in prototyping and production tooling.

Titanium’s best mechanical attributes can be found when alloyed with other metals. Ti-6Al is 40% lighter than 17-4 PH stainless steel yet boasts a much higher strength-to-weight ratio, making it an ideal choice for industries that value lightweight components.

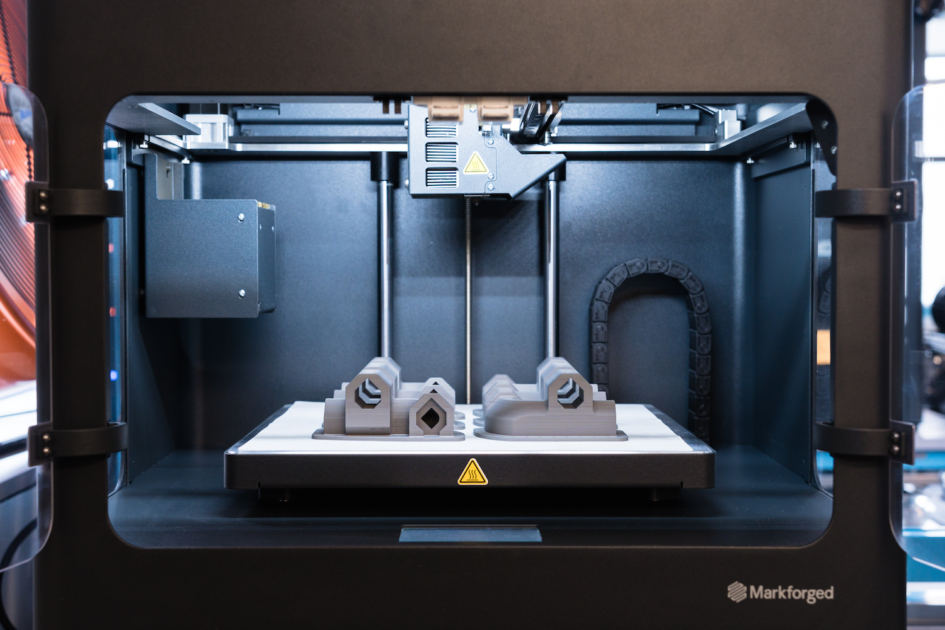

The PX100 binder jetting system from Markforged offers exceptional precision for high-volume metal additive manufacturing, delivering speed at scale and adding a new dimension to the Markforged Digital Forge.

Less common titanium variants in additive manufacturing are Titanium Ti GR23, grade 23, a biocompatible metal, and Cp-Ti (Pure Titanium), grade 1, widely used in the medical industry for prosthetics and implants.

Know your print processes

Powder Bed Fusion

Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM) are all 3D printing technologies that fall under the Powder Bed Fusion (PBF) family. PBF printers evenly distribute a fine layer of metal powder across a build plate and then selectively melt a cross-section of the part at each layer.

The advantage of PBF machines is that they can achieve very high resolutions, which is beneficial for more precise parts. Unfortunately, their high cost (sometimes over £1 million, including facility upgrades and post-processing equipment) and the need to handle hazardous metal powders make them a difficult option for many.

Binder Jetting

Binder jetting printers like the Markforged PX100 follow the same principle as PBF, but instead of sintering with a laser, a binder is deposited over the metal powder. This creates a loosely adhered metal part which is sintered in a furnace to create the finished part.

Binder jetting enables rapid production, with multiple parts printed simultaneously and all sintered in a single furnace. The PX100 offers industry-grade performance and speed with a lower cost of entry than PBF machines.

Bound Powder Extrusion

Bound Powder Extrusion, a newer metal AM technology deployed by the Markforged Metal X, uses metal powders bound in a waxy polymer, melted, and printed like FFF 3D printing. The resulting “green” part is then washed and sintered, like binder jetting, to remove non-metal particles and create the final metal component.

Perfect for those on a budget as it costs under £200,000, bound powder extrusion is a much safer option since the metal powder is no longer hazardous when bound within the filament. The downside is that parts may take longer to manufacture due to the multistep process.

Direct Energy Deposition (DED)

DED technologies deposit and fuse metal feedstock from a printhead, adding layers to a part. Examples of DED machines include Electron Beam Additive Manufacturing (EBAM) and Laser Material Deposition (LMD).

These machines are excellent for large parts and are safer to use since they don’t require handling metal powders. However, their resolution tends to be lower, and their costs are like PBF machines, leaving investment to the big firms.

Summing up

Titanium 3D printing has a high investment cost paid back by in-house prototyping and manufacturing. The more you scale, the better the ROI.

Metal 3D printers can economically produce individual pieces in small and medium batches. This is a more cost-efficient option than methods such as milling, turning, or casting since the production costs do not depend on the complexity of the component. Instead of relying on expensive tools or complex, specialised solutions, all that is needed to create titanium products successfully is a 3D printer and metal powder.

Find out more

To find out more about 3D printing titanium, call us on 01765 694 007 or email [email protected].