The Formlabs Form 3L and Form 3BL boast feature sets that are revolutionising post-processing for benchtop SLA printing, and with the addition of the Build Platform 2L, the workflow is revolutionised even further.

Using cutting-edge Quick Release Technology, it streamlines post-processing for benchtop SLA and enables 24/7 operations when used with the Form Auto.

Ideal for large-format applications such as human-scale anatomical models and industrial-strength moulds, the stainless-steel material of this product is strong and gouge-resistant, allowing you to drastically reduce post-processing time.

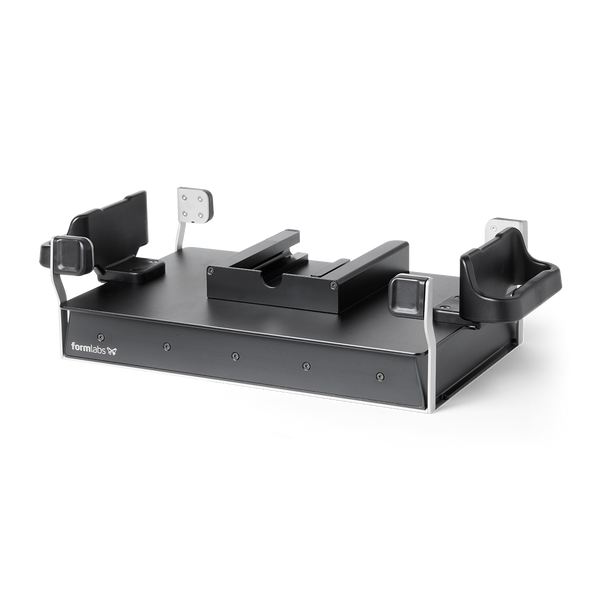

The Build Platform 2L is the latest evolution of Formlabs’ Build Platform 2 product; empowering customers to create high quality prints with repeatable precision and superior surface finish.

Before getting ahead of ourselves and discussing the Build Platform 2L in more detail, let’s recap on the printing process that utilises it.

LFS – an upgrade to SLA

Formlabs printers use an augmented (and proprietary) version of stereolithography called Low Force Stereolithography (LFS). LFS significantly reduces peel forces on prints, enabling light touch snappable support structures thanks to small touchpoints.

Another critical component is the flexible film at the base of the resin tank, which gently peels away as the build platform pulls parts up. This reduces stresses on the print, which pays dividends for surface finish and clarity.

The Build Platform’s role in the LFS process is to enable the quick, clean, and controlled release of printed parts from the build platform. Parts don’t stick because the flexible print surface releases parts by flexing upwards.

However, removing 3D printed materials from build platforms can be difficult, particularly if the resin is dense. Often, a scraping tool or putty knife must be used.

Enter the Build Platform 2L.

The New Build Platform 2L

The improved flexibility of the Build Platform 2L makes it easy to remove parts in high-density resins such as Rigid 10K Resin, encouraging users to experiment more with their 3D printing projects.

The Quick Release Technology is a patented feature that incorporates a flexible stainless-steel sheet on a handle frame. Applying pressure inwards on the handles causes the steel to flex, releasing parts instantly.

The durable, stainless steel print surface is free of gouges, ensuring robust, long-lasting performance. This is a product build to last thousands of print cycles, saving you money and maximising uptime in the process.

However, before printing with the Build Platform 2L, you should still take the necessary preparatory steps to ensure successful results, such as orientating your model efficiently, and selecting the best support structures. Certain orientations and support options may be better suited for release from the build platform.

Solving resin removal problems

Removing 3D printed materials from build platforms can be difficult when the resin is dense, such as Rigid 10K Resin.

To mitigate this issue, some users print the moulds at an angle. This makes it easier to remove the parts, as there are no flat surfaces adhering to the build plate, and any support structures or rafts are simpler to eliminate without causing damage.

Creating moulds at an angle is an attractive prospect, but it requires increased print time and can even be impossible, depending on the size of the mould.

Industrial moulding demands that the properties of the material making up the part remain consistent throughout. Unfortunately, prior to the introduction of the Build Platform 2L, 3D printing could not satisfy this requirement for strong moulds.

With its incredible flexibility, the Build Platform 2L makes it easier to print in high-density resins such as Rigid 10K Resin – even the removal of parts has become easier and much faster. Gone are the days of arduous post-printing processes!

Find out more

To find out more about the Build Platform 2L, call us on 01765 694 007 or email [email protected].

Image credits: Formlabs.