While 3D printing large parts that are strong and durable is possible with high-performance plastics, Continuous Fibre Reinforcement (CFR) technology with the Markforged FX20 offers even better results.

CFR uses a build material such as Onyx for the outer shell and infill and a composite like carbon fibre as a reinforcement inlay.

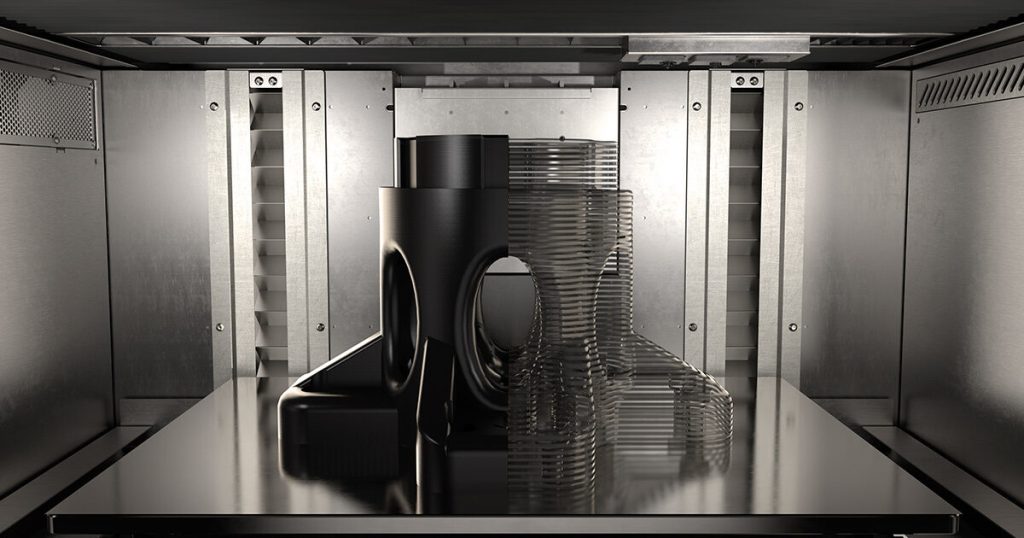

The Markforged FX20 has a heated, enclosed, and optimised build chamber supporting high-temperature materials like ULTEM™. Its large build size and unique Continuous Fibre Reinforcement ensure large parts are printable in a single session, eliminating the need for multiple print sessions and extra assembly.

The FX20 is also the fastest composite printer in the Markforged line-up, with build speeds up to eight times faster than the desktop series.

Why CFR?

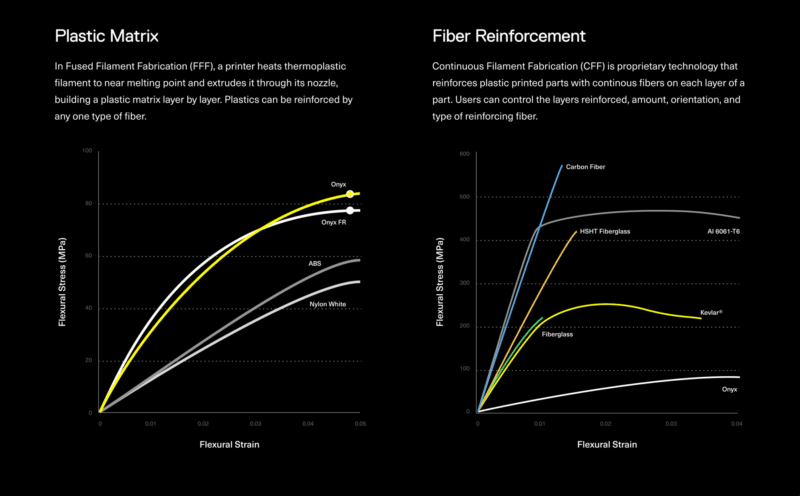

CFR produces stronger, stiffer, and more durable parts than filled and unfilled plastics by reinforcing a part’s perimeter, select features, or entire layers with continuous carbon fibre.

The FX20 adds another material to the mix – ULTEM 9085 – a high-strength, heat-resistant superplastic for custom, robust fixtures.

CFR produces stronger parts than standard FFF because a secondary nozzle inlays long-strand Continuous Fibre Reinforcement selectively through the part, effectively reinforcing the structure with a high-performance composite.

The advantage CFR has over carbon fibre-filled filaments is that FFF filaments are infused with short carbon fibre strands, while CFR introduces long-strand fibres, which are fused to the part, transforming its mechanical characteristics.

Why the Markforged FX20?

The Markforged FX20 is a game-changer for large-scale 3D printing and global manufacturing. It has a precision design, high-end sensors, an adjustable heated build chamber, and a massive 525 mm x 400 mm x 400 mm build volume, making it the most powerful and reliable CFR 3D printer on the market.

The most valuable feature is the three-nozzle, direct drive print head, which can print two polymers and one fibre simultaneously.

That three-nozzle configuration means you get print speeds up to eight times faster than other CFR 3D printers with support for temperatures up to 200°C, letting you print high-temperature ULTEM with exceptional accuracy.

Fabricating parts directly at the point of need takes just the click of a button. You also get access to Markforged’s Digital Forge platform, which uses federated fleet learning (AI/ML + data) to improve the 3D printing process.

The Digital Forge is Markforged’s unique metal and carbon fibre additive manufacturing platform. It includes software + materials + printers, bringing the power and speed of agile software to industrial manufacturing.

Industrial-grade materials

The FX20 supports the following materials:

Plastics

- Onyx: A fusion of engineering nylon and chopped carbon fibres.

- Onyx FR: A fire-retardant version of Onyx.

- Onyx FR-A: A variant of Onyx FR purpose-built for the the aerospace, transportation, and automotive industries.

- ULTEM™ 9085: A flame-retardant, high-performance thermoplastic.

Support materials

- Support for ULTEM: A support material that reduces shrinking and bonding problems when printing with ULTEM.

Fibres

- CF-U: Carbon Fibre for ULTEM.

- Carbon Fibre: A reinforcement material that can yield parts as strong as 6061-T6 aluminium.

- Carbon Fibre FR-A: A fire-retardant version of Carbon Fibre.

Onyx and ULTEM are primary build materials, while all composites are reinforcement materials. This gives you lots of ways to manufacture tough, durable, and strong parts capable of replacing metal and improving on performance plastics.

Extreme accuracy and precision

The FX20’s 84L heated build chamber is designed for optimal results, utilising a verified flat aluminium print bed, automated calibration, dual convection heaters, a 3-nozzle print head capable of fast heating and extrusion, and an array of sensors.

The frame has high-resolution linear encoders, a precision gantry, a closed-loop extrusion control, and high-powered servo motors managed through a newly implemented print file format for further accuracy and control.

The FX20 delivers an industrial-grade, large-format 3D printing experience from the hardware up, with no stone left unturned for accuracy and quality.

View the Markforged FX20 datasheet to find out more.

Summing up

The Markforged FX20 is the perfect option for those looking to expand their large-scale capacity and venture into engineering-grade composites that are strong, stiff, and durable.

With the capability to 3D print high-temperature materials like ULTEM, the FX20 is the most reliable and powerful CFR 3D printer available, with extreme accuracy and precision that ensures optimal print results with every print session.

Find out more

To find out more about CFR 3D printing, call us on 01765 694 007 or email [email protected].

Attend our in person FX20 event on the 25th April to see the printer in action! Sign up here

book an appointment with Kevin

book an appointment with Kevin

Image credits: Markforged.