5 Tips That Will Reduce Your 3D Printing Cost

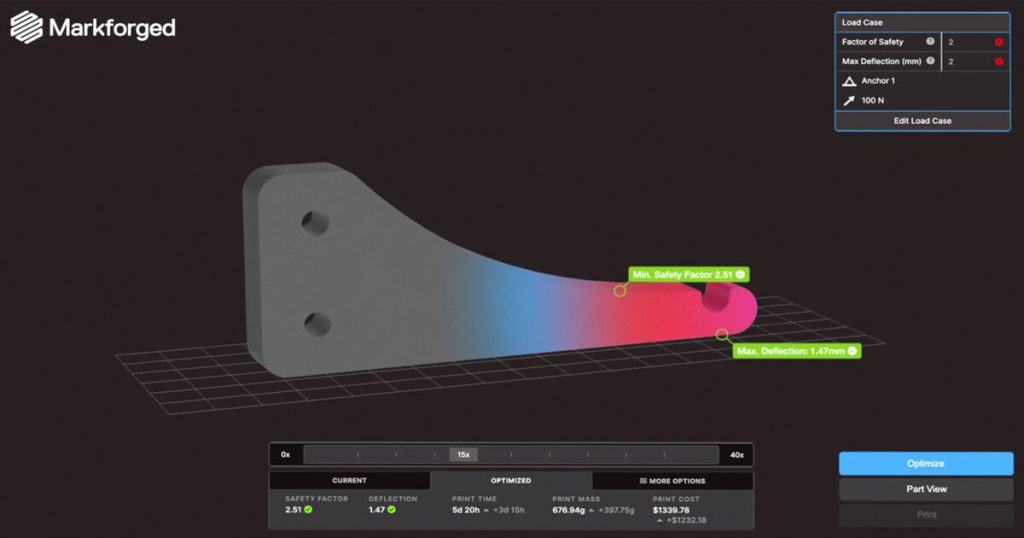

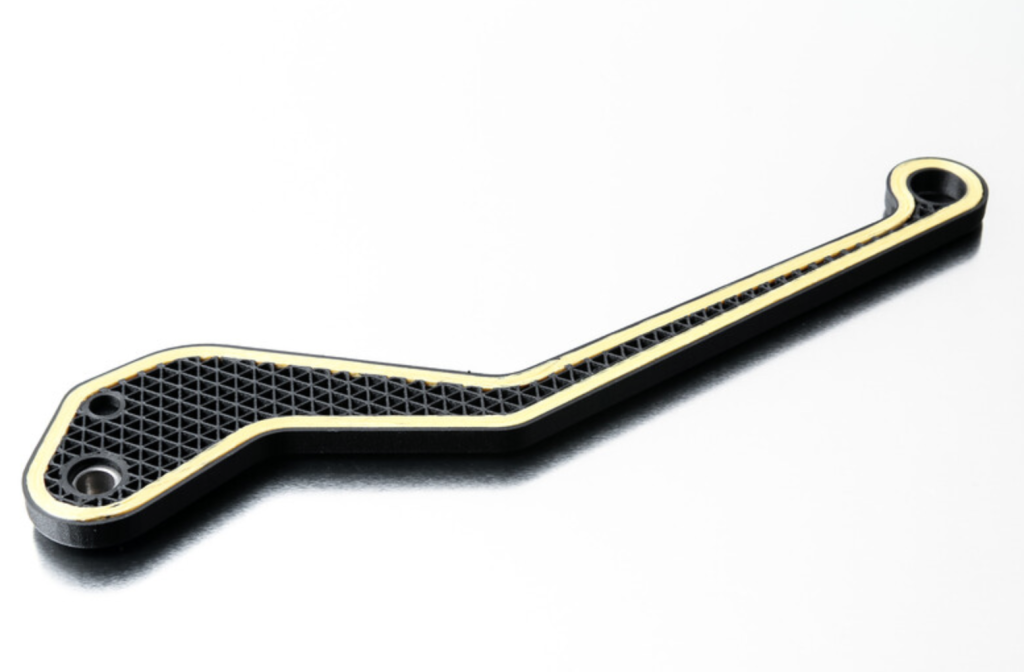

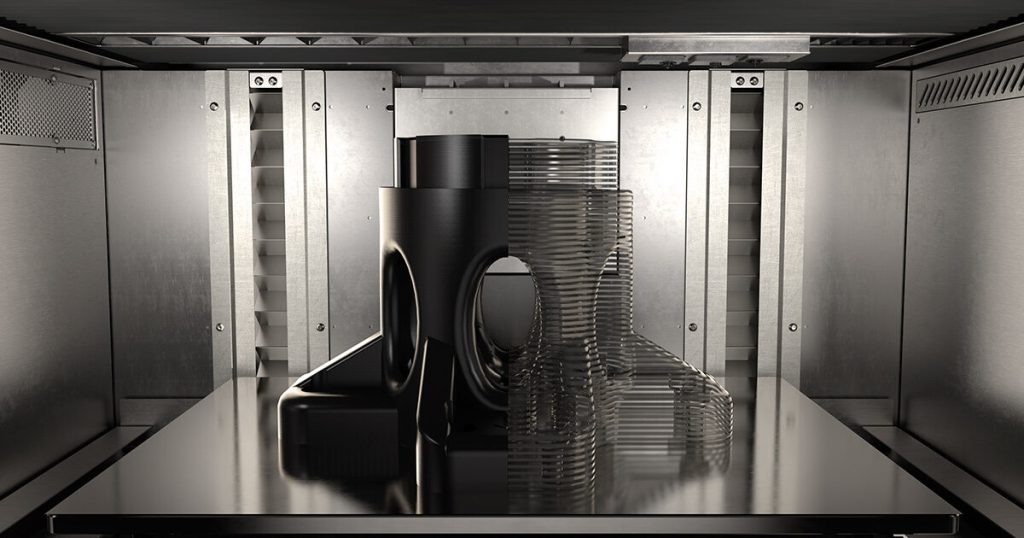

Reducing 3D printing costs requires looking past the sticker prices for equipment and materials. Other factors add up, too. Manual labour for software prep and part finishing after builds, that’s money and hours. Excessive energy use ticks the electricity bill up, and failed print jobs mean wasted materials and time,

5 Tips That Will Reduce Your 3D Printing Cost Read More »