If you want your 3D prints to come out fast, you can buy a speedier 3D printer or adjust your settings and workflow to get faster results.

Picking suitable materials, determining the optimal print resolution, orientating your part for the fastest build path, and choosing an efficient infill pattern are just some tricks you can do to print faster and increase uptime.

This article reveals a few more tricks to increase your 3D printing speed, starting with the most critical of them all.

Pick the most suitable AM technology

The starting point for fast 3D prints is the technology you use.

It is not always clear which technologies and 3D printers suit your needs. However, some technologies and printers are speedier than others. Consider your application requirements carefully to make the best choice.

FFF

FFF 3D printers create models by layering melted thermoplastic through a nozzle onto a build plate. This technology is fast at building basic prototypes as well as small, low-cost parts that would otherwise be machined. It is typically slower than resin-based 3D printing for medium-sized and large parts.

If print speed is a priority, a larger nozzle size and print resolution will result in shorter print times because less layers and more filament is extruded.

Fast printer example

- Markforged FX20: This has a turbo mode that prints high-temperature thermoplastics with continuous fibre reinforcement up to 8x faster than other Markforged printers.

Resin (SLA, LCD, DLP)

Resin printers cure a liquid resin in layers with UV light and/or heat. Using like-for-like print resolution and when printing multiple copies in the same print run, SLA (stereolithography), DLP (Digital Light Processing), and LCD (Liquid Crystal Display) technologies can be significantly faster than FFF, especially at scale.

In terms of speed, SLA 3D printers heavily rely on layer thickness. The higher the resolution of the model, with thinner layers, the more time the printer will take due to the increase in layers and slower curing times.

SLA technology offers a different challenge with 3D printing than LCD and DLP techniques. In the case of SLA printing, the model’s layer thickness and geometry affects the speed as the laser source prints point-by-point.

Therefore, a hollow model is printed faster than a solid one. On the other hand, with LCD and DLP, the model’s height is more critical than its geometry.

Fast printer example

- Formlabs Form 3+ and Form 3B+: These print between 20% and 40% faster than the Form 3 series, thanks to hardware and software advancements.

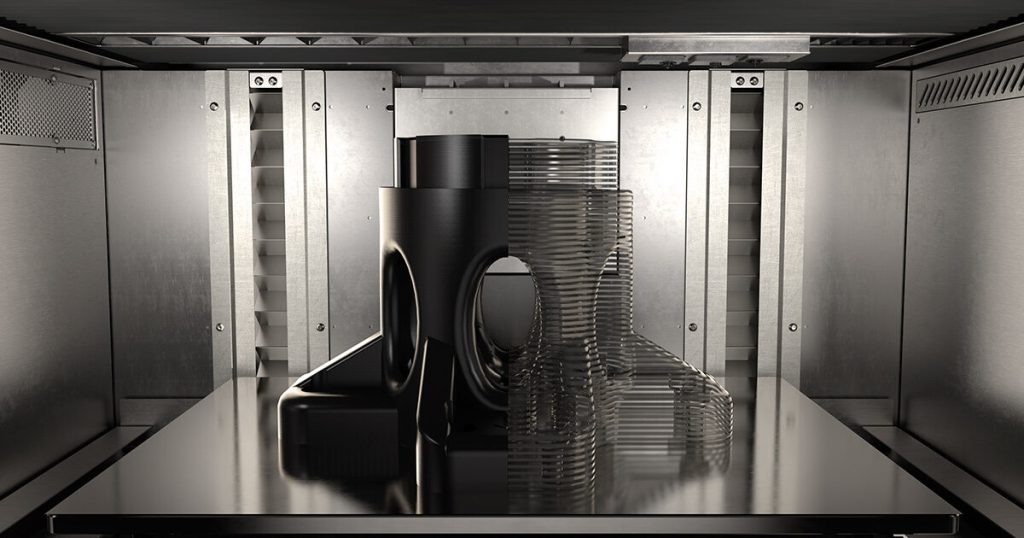

SLS

SLS (Selective Laser Sintering) printers use a Recoat or Doser assembly to spread layers of powder dispensed from the printer’s material storage hopper into the build chamber, ready for sintering with the laser. SLS is typically slower than FFF and resin-based printing but lets you nest parts and reduce wasted print volume.

With SLS printing, optimising the shape and orientation of a model is essential for decreasing the print time. Objects should have a minimum cross-sectional area and be placed as close to the bottom of the build area as possible.

Consciously choosing a more convenient orientation is essential, as a horizontally made tube will build more quickly than one made vertically.

Fast printer example

- Formlabs Fuse 1+ 30W: Features a powerful 30W laser with scan speeds of up to 12.5 metres per second.

Pick the fastest material for the job

The printing rate of FFF machines depends mainly on the material used: PLA filament typically prints up to 100 mm/s, ABS at 50 mm/s, PETG at 50 mm/s, nylon at 40 mm/s and TPU at 20 mm/s. The physical characteristics of the respective materials, such as melting point and malleability, affect the speed at which these machines print.

For Formlabs printers, Draft Resin is the fastest resin due to its layer height of 100 to 200 microns. It offers a four-fold speed increase in printing compared to Standard Resins, which is ideal for bulky parts that need to be printed with speed.

Note that the build time of any 3D model depends on the material and the printer settings you deploy to print the material.

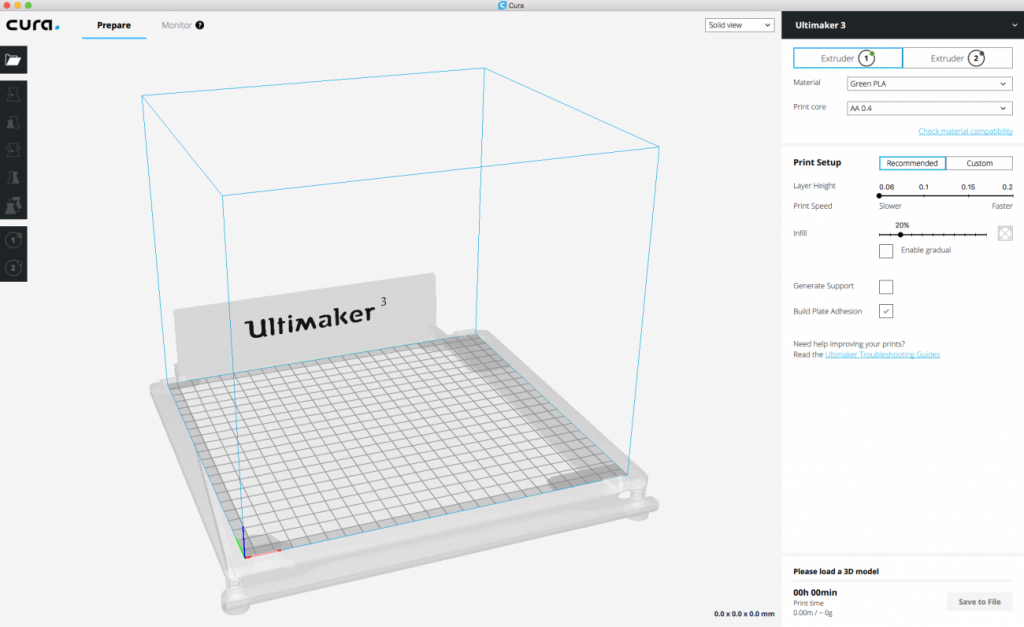

Slicing software settings

Different slicing software packages can help to adjust the speed of 3D printing. But it’s essential to keep in mind that altering speed settings without other parameters, such as jerk and acceleration, can lead to a decline in product quality.

To illustrate the difference between speed and acceleration, let’s use an analogy. In FDM printing, the printhead cannot jump from 0 to 40 mm/sec all at once – it needs to gradually get up to that speed. When the acceleration rate is set too high, it can create unpredictable movements, potentially causing the print to fail.

Print size and complexity

Printing time can depend on the size of a 3D-printed part. Generally, wider parts have more layers and more complex cross-sections, necessitating more material and time.

Technologies like LCD and DLP harden layers at a rate of 2-10 seconds and utilise short printing times. While FDM’s layers require more filling and overall time, LCD and DLP can be advantageous for tall models.

Printing a complex model with many small parts can demand more time and precision. For best results, we recommend arming your printer with balanced printing speeds to preserve small details. Additionally, you must assess how much support is necessary to prevent large overhangs from collapsing.

Print resolution

The resolution of a 3D model is determined by how many distinct layers it contains, known as the layer height.

The most common layer heights for FFF printers range between 0.05-0.1 mm, and resin 3D printers can work with layer heights of 0.01-0.2 mm (10-200 microns).

The number of layers heavily impacts print speeds, as more layers mean a longer print time. You can print faster by increasing the layer height, but beware that print quality may suffer as the surfaces may not blend smoothly.

Model infill

The material and structure inside the model is called the infill, and its content can vary greatly depending on the technology and material used in the 3D printing process.

Regarding FFF and resin printers, you can tweak the infill pattern and percentage to adjust weight, strength, and durability.

Settings range from 0%, which is entirely hollow, to 100% for something that is solidly packed. For typical 3D prints, a 15-50% density is recommended, while functional pieces call for a denser fill of 50-100%.

SLS requires no infill because it is a self-supporting technology, and you can hollow out models to save weight and reduce build times.

Find out more

To learn more about the tips in this article and for expert advice on fast 3D printing, call us on 01765 694 007 or email [email protected].