In today’s complex additive manufacturing landscape, simulating part performance and predicting problems prior to 3D printing is the optimal way to keep ahead of the competition. Simulation tools help to ensure expected results by validating designs and optimising settings for more efficient builds.

The use of 3D part simulation is instrumental for 3D printing workflows, providing a clear understanding and visualisation of the detailed processes involved in creating highly accurate and superior quality products.

Simulation is especially important when developing costly components with advanced 3D printing technologies. It not only forecasts the result of the manufacturing process, thereby minimising waste, but also enhances build efficiency.

What is 3D simulation?

3D simulation involves taking a 3D model of a physical object and evaluating it within a virtual space.

Through this process, users can assess an object’s performance, durability, and resilience without the need for any physical testing.

Computer simulation significantly shortens the product development timeline, optimises manufacturing efficiency, and opens up possibilities for additional applications and features.

Finite element analysis (FEA) is the most widely used simulation method. It involves employing a mathematical model to predict the stress and strain that parts might undergo in a virtual setting – this provides valuable insights into potential breakage or deformation in real-world conditions.

However, the FEA method requires structural experts to analyse and interpret the data. To simplify the process, contemporary 3D simulation tools are being specifically tailored for additive manufacturing. Here’s where slicing software, like Markforged’s Eiger, enters the equation. These pieces of software leverage FEA for design validation, but the data extracted is incorporated within the slice-and-print workflow, ensuring its usability for a wider user base.

How 3D part simulation works

To validate part performance and accelerate design cycles with 3D part simulation, you need simulation software such as Markforged Eiger.

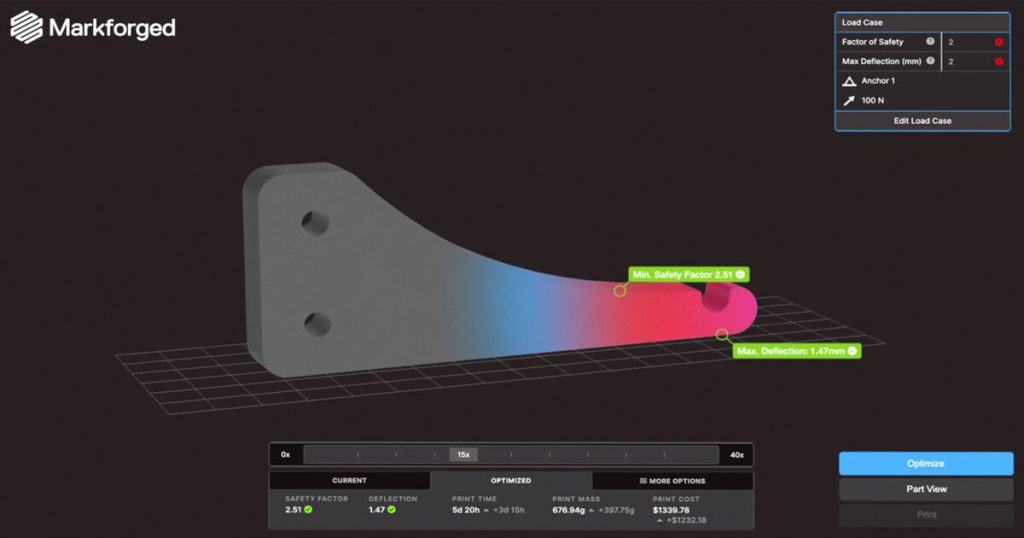

Eiger is a proprietary software tool for Markforged 3D printers. The Simulation feature allows you to confirm whether a part will meet performance criteria and tweak settings before printing. Its advanced features are incredibly helpful, increasing productivity, maximising machine efficiency, and reducing wasted materials.

Eiger’s Simulation offers two modes: Validation and Optimisation. The Validation mode uses existing parameters to assess a part’s readiness for printing, while the Optimisation mode delves deeper to find the optimal settings that fulfil the targeted performance specifications.

There are also other 3D part simulation software options available in the market, like Ansys FEA software and Onshape. These platforms offer compatibility with multiple printers and scalability for varying production capacities

What are the benefits of 3D part simulation?

Designing for Additive Manufacturing (AM) requires consideration of multiple elements, such as the heat dispersion from each printed layer to manage residual stress, and the strategic placement of support structures to prevent deformation and warping.

Utilising simulations in 3D printing can significantly prevent print failures and geometric disqualifications, saving both time and resources. By simulating the printing process, production risks can be evaluated and mitigated.

Furthermore, simulation can predict the microstructural properties of the end product, optimising the production process to enhance speed, reduce post-processing operations, or improve accuracy.

Simulation can occur pre- or post-support structure generation, allowing designers to implement adaptive support structures that minimise deformation, alter the print orientation to decrease heat dispersion, or even modify the 3D model’s geometry to elevate the product quality.

Moreover, simulation can inform efficient build modifications, reducing material waste and accelerating print times without impacting the surface finish.

Find out more

To learn more about the capabilities of Markforged Eiger and the transformative power of 3D simulation, reach out to us at 01765 694 007 or via email at [email protected]. We are committed to helping you utilise additive manufacturing to its fullest potential and look forward to assisting you with your 3D printing needs.