The strength of 3D printed components is determined by several factors, including the material, printing temperatures, layer height, the infill pattern and density, and any post-processing techniques employed.

While printing stronger parts is sometimes as simple as switching to a stronger material, other measures like increasing layer thickness can have excellent results.

This article covers methods you can use to increase the strength of 3D printed parts without affecting the quality of the finish.

Use stronger materials

First, consider upgrading to a stronger material out of the box.

PETG, Polycarbonate (PC), and Tough PLA are strong upgrades over standard PLA and ABS in Fused Filament Fabrication 3D printers.

You can also use carbon fibre-filled filaments like Essentium PET-CF and PA-CF, which are infused with short-strand carbon fibres to increase strength.

For even greater strength, Markforged 3D printers like the Mark Two (desktop) and FX20 (industrial) infuse nylon parts with continuous strands of composites, including fibreglass and Kevlar, producing parts stronger than 6061 aluminium.

Increase the infill density

Raising the infill density of a 3D print can strengthen it in any direction.

Functional 3D printed parts such as brackets that must withstand loads or forces are best printed with a higher infill percentage.

The ideal percentage for most functional parts is 50% to 70%. Although choosing 100% infill density for a solid structure is still possible, this increases material usage and build time and may not yield meaningful strength improvements.

Optimise the infill pattern

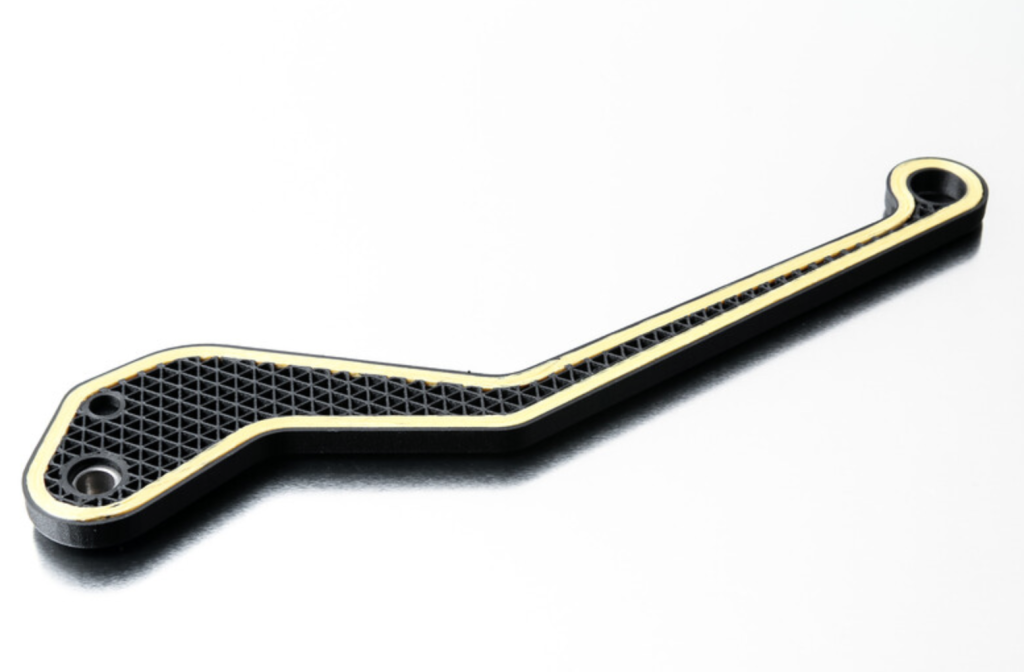

Infills are interior grids that act as internal support structures, stiffening the final product to avoid wall deformation.

Hexagonal infill patterns, consisting of tessellated hexagons, provide the best strength-to-weight ratio of any infill pattern. While printing with hexagon infill may be slower than other methods, it offers excellent strength.

Triangular infill patterns offer high mechanical strength when stress is applied perpendicularly to one side of the printed part.

Add fillets and chamfers to thin parts

If you have thin parts on your 3D model, you can add fillets to those areas to strengthen them and make them less likely to snap. This will also reduce stress on the model during printing and make the entire print more reliable.

Adding a fillet to delicate parts of a 3D model can help reinforce them by creating an area of thicker material and a more gradual transition from one area to another. This gives the parts greater resilience and makes them less prone to breaking.

Use the strongest part orientation

You can alter the strength of a 3D print simply by changing the part orientation or the way the part is oriented on the print bed.

When manufacturing parts with FFF 3D printers, these parts have anisotropic properties, so they are stronger in the X-Y direction and weaker in the Z direction.

It is important to orient the prints in the correct direction with respect to the direction of tension load to maximise mechanical strength.

Increase the wall thickness

Increasing the wall thickness (outer wall) of a 3D print can significantly improve its strength and enable the integration of characteristics such as overhangs.

“Wall Line Count” and “Outer Line Width” are used to measure the wall thickness. For stronger parts, increase the wall thickness to 2-3 mm and the top and bottom thickness to 1.6-2 mm to match the material.

A thicker wall has higher strength than a thinner wall, with the caveat that it increases the build time and consumes more material.

Print with thinner layers

3D printing technologies construct objects layer-by-layer, leading to weaker bonds in the Z-axis versus the X- and Y-axes.

Printing with thinner layers can improve interlayer adhesion and especially with materials with a higher printing temperature, like ABS. It also improves surface finish by reducing the appearance of large, visible layer lines.

Thinner layers are helpful for stronger bridges, less warping, and no sagging, and they create fewer air gaps, decreasing the chances of voids.

The downside to printing with thinner layers is increased build times, so you must balance layer height and print speeds.

Find out more

To find out more about high strength 3D printing, call us on 01765 694 007 or email [email protected].