Designing a part for additive manufacturing requires different considerations than subtractive processes like injection moulding and machining due to the underlying technology. Enter DfAM.

Design for Additive Manufacturing (DfAM) is a set of design strategies that enhance the manufacturability and cost-efficiency of 3D-printed parts. DfAM uses 3D printing to its fullest potential, enabling the production of products and parts that meet the demands of specific applications.

DfAM in a nutshell

DfAM is an ongoing area of exploration that involves creating and optimising parts, assemblies, and products to maximise the advantages of additive manufacturing processes for product development. This involves capitalising on the potential of 3D printing technologies and accompanying software.

DfAM influences how we approach 3D-printed part design when part geometry, build orientation, processing parameters, material properties, and other factors impact the manufacturability of 3D-printed parts.

The components of DfAM

DfAM comprises the following components:

- The fundamentals of 3D printing, such as build volume, shrinkage and distortion, surface finishes, and support structures.

- Understanding the most suitable technology for the part. Note that some DfAM optimisations are dependent on the technology. For example, FFF parts are anisotropic, so the mechanical properties depend on the build direction.

- Understanding the most suitable materials for the part.

- Design guidelines, including lattice structures, triangulation, detail resolution, and dimensional accuracy. For designing and optimising parts for 3D printing, engineers can use tools such as Fusion 360.

- Optimisation opportunities like feature integration, part consolidation, and thinner walls to reduce costs.

- Post-processing considerations such as heat treatments and support removal.

- Cost calculations and comparisons. For instance, estimating the cost and time of printing a part based on available hardware and consumables.

Design techniques for additive manufacturing

Additive manufacturing offers unparalleled design freedom, with techniques such as topology optimisation, generative design, lattice structures and part consolidation helping designers achieve maximum performance from their 3D-printed components.

Topology optimisation

Topology optimisation takes a design and reduces areas of the part not subject to stress based on pre-determined loading conditions.

Through several successive cycles, topology creates lightweight structures that abide by specific safety limits for stress failure.

Generative design

This technique doesn’t need an initial form, focusing on the incorporation of ‘keep’ and ‘avoid’ zones to create an optimally designed component for a given material.

Generative design can condense many elements into one component, slashing material consumption to save weight and costs.

Lattice structures

Lattices offer advantages of lightweight construction and high strength, aesthetic advantages such as open spaces, and structural benefits for shock absorption, impact control and vibration/noise dampening.

DfAM utilises lattice structures, as well as other open-cell structures, to optimise weight and performance for highly optimised 3D-printed components.

Part consolidation

Part consolidation is the process of redesigning and reconfiguring assembled components into a single, more complex unit that eliminates assembly and can be fabricated in one step.

Consolidation is a critical component of DfAM concerning assemblies, helping maximise a printer’s build volume and capabilities.

Software is crucial

More DfAM software solutions like those from Autodesk and Altair are becoming available. This gives manufacturers more opportunities to optimise their part designs with the added benefit of automation through generative design and simulation tools.

With these tools, manufacturers are taking advantage of the potential that additive manufacturing offers right at the design stage, streamlining the process and making it more efficient.

The DfAM product development workflow

3D printing has revolutionised the product development process by enhancing existing, traditional manufacturing processes. It provides a tool for iterative feedback and design improvement, allowing for faster, more efficient product development without changing the fundamental methodology or nature of the design.

Integrating DfAM into your AM workflow can be quickly and effectively executed by intentionally designing within a chosen technology such as SLA or SLS.

This step-by-step process typically includes the following:

- Determine the purpose, goals, and constraints of the design.

- Analyse both the economic and functional needs of possible solutions.

- Select an appropriate manufacturing process.

- Begin constructing your design to satisfy the established criteria.

- Modify the design to align with the manufacturing method.

- Assemble the prototype using chosen fabrication techniques.

- Evaluate component performance and measure against the desired operation.

- Redo any necessary steps until the desired results are achieved.

The significance of DfAM in product development is it allows manufacturers to take advantage of different infill rates, structures, and build techniques to expedite the printing process and reduce material use. It also takes these benefits a step further by adding optimised performance to the mix.

Find out more

To find out more about DfAM and how to incorporate it into your workflow, call us on 01765 694 007 or email [email protected].

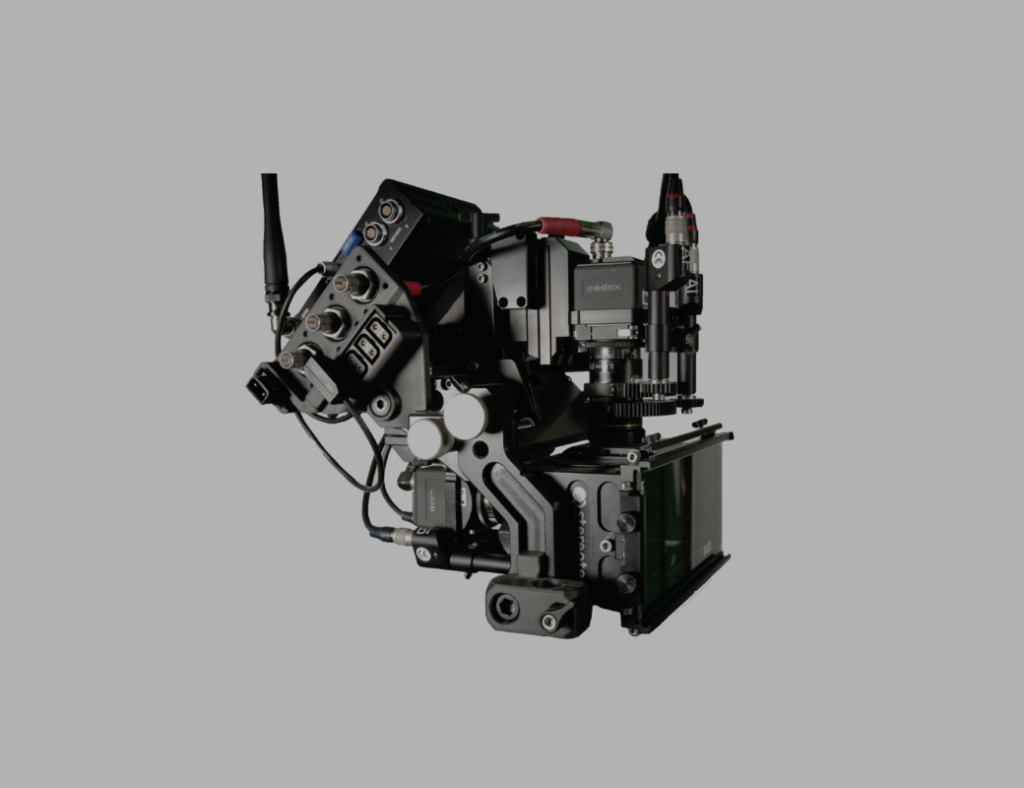

Top image credit: Formlabs.