Formlabs recently launched an Automation Ecosystem to revolutionise additive manufacturing for SMEs. This new system encompasses Form Auto for continuous production, Fleet Control for optimised fleet management, and the High-Volume Resin System for enhanced printing capacity.

By adopting this technology, SMEs can significantly boost productivity, lower labour costs, and avoid machine downtime costs.

The Automation Ecosystem makes it easy to scale 3D printing production from single to multiple printers without increasing complex management tasks, empowering multi-user, and multi-material printer fleets with continuous production.

Formlabs tests show the Automation Ecosystem can increase productivity by three times, reduce labour costs by up to 80%, and reduce up to 96% of packaging waste – a golden trio that will transform how SMEs approach AM.

The Automation Ecosystem

Automation is critical for SMEs using additive manufacturing because it reduces or eliminates the need for manual labour, decreasing manufacturing costs, increasing production speed and accuracy, and allowing for more uniform output.

Automation also allows for greater flexibility when scaling up production and responding quickly to changing customer demands.

However, putting automation into practice is not always straightforward because of fragmented ecosystems and siloed applications.

The Formlabs Automation Ecosystem solves this problem with one integrated, automated solution comprising three components:

Form Auto

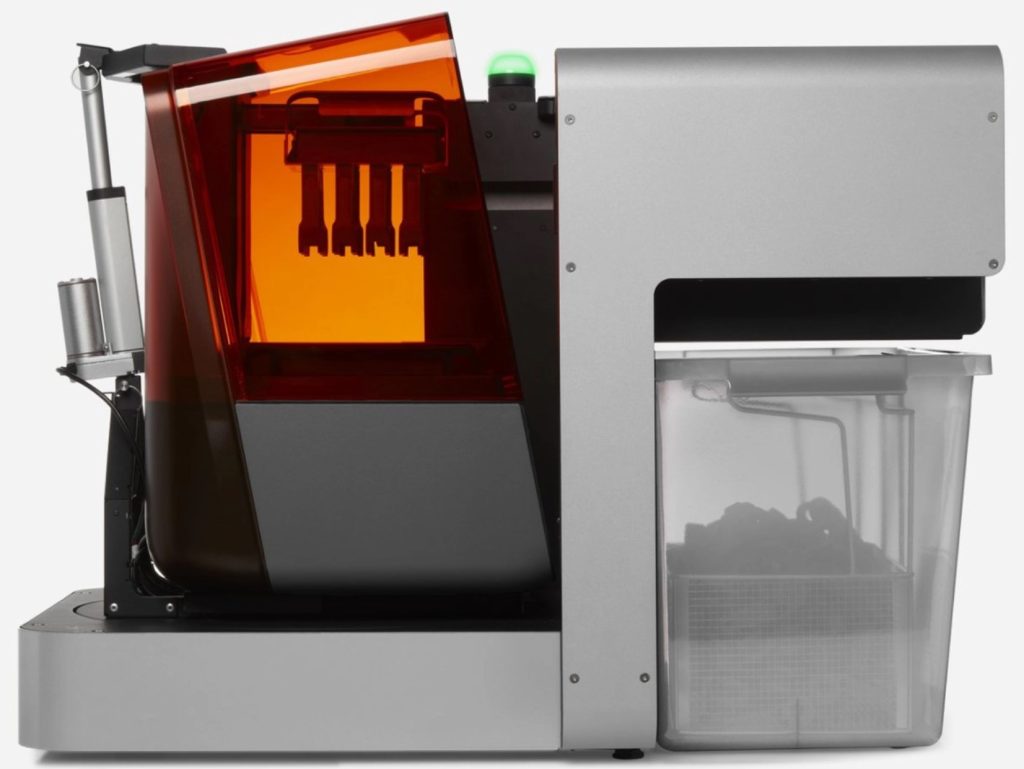

The Form Auto eliminates labour-intensive manual part removal. The hardware extension works with Form 3 and Form 3+ 3D printers, allowing users to use its automated 24/7 printing and Quick Release Technology for seamless part removal.

With Form Auto, your SME can boost production efficiency by increasing throughput and drastically reducing labour costs.

How it works

Equipped with the exclusive Quick-Release Technology of the Build Platform 2, Form Auto can automatically remove parts from the Form 3/B/+ printer, detach them from the platform, and deposit them in a handy receptacle.

A built-in camera captures and stores the releasing action so you can keep an eye on production from any place – whether in the same building or across the globe.

Fleet Control

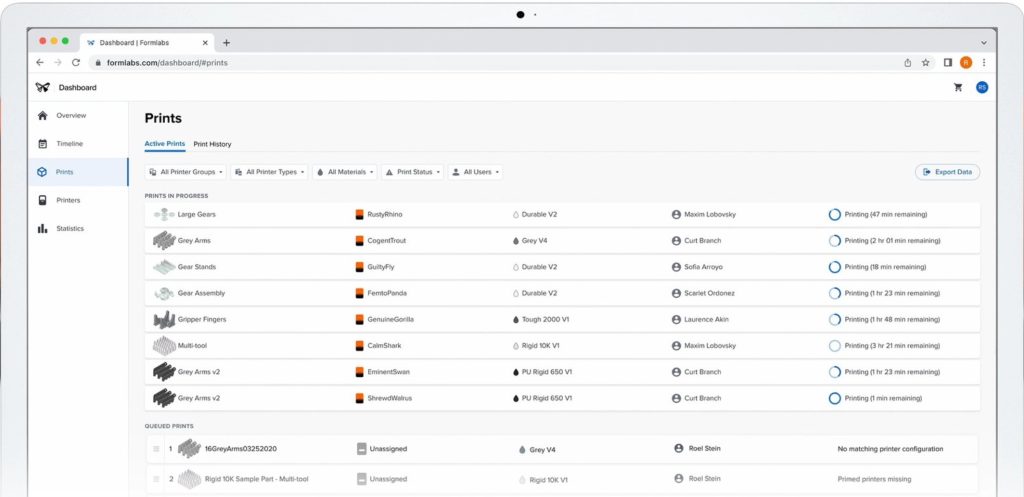

Fleet Control revolutionises the way you manage your 3D printer fleet. The platform, integrated within Formlabs’ Dashboard and PreForm software, features centralised queue management and automated printer assignment to maximise production, performance, and efficiency when using 3+, 3B+, 3L, and 3BL printers.

With Fleet Control, your SME can optimise its workflows.

How it works

Fleet Control is an innovative solution for managing groups of Form 3 Generation printers through PreForm and Dashboard.

It automates print jobs to ensure the most suitable printer is used and centralises printer queues in Dashboard. This makes it easier for users to view and edit jobs and duplicate or reprint them. Fleet Control simplifies the management of your fleet of Formlabs 3D printers and streamlines the entire workflow.

High-Volume Resin System

The High-Volume Resin System maximises resin capacity, transforming 3D printing operations with a five-litre capacity — five times larger than the standard vat size.

Outfitted with a Resin Pump, production runs are more efficient, with fewer pauses for cartridge replacements and reduced packaging waste.

Suitable for Form 3+, Form 3B+, Form 3L and Form 3BL, this technology helps simplify workflows while optimising output for SMEs.

How it works

The High-Volume Resin System from Formlabs provides an uninterrupted production process, fostering extended production periods without stopping for material changes. The Resin Pump ensures effective and efficient material dispensing, while the five-litre vessel eliminates the worry of running out of material.

Fleet Control and Dashboard options alert operators when a top-up is necessary, so you won’t ever have to return to a job with insufficient material.

Spectra case study

At the Formlabs Manufacturing Service Bureau, a print farm boasting a whopping 180 SLA and SLS 3D printers hums away under the watchful eyes of two operators overseen by Print Farm Manager Chris Pauwels. This impressive farm produces around 440 parts on any typical day, thanks to the Automation Ecosystem.

According to Pauwels, these programs “replace five printers” as they allow for cleaning in large batches, thus removing the need to clean off each platform separately.

The feature of these programs enables the bureau to successfully remain agile and lean in the face of new requests, such as for new material or a large production order, as in the case of the emergency swab production workflow Formlabs developed in 2020.

The Automation Ecosystem developed by Formlabs is designed to diminish the work needed to maintain the printer’s operation ─ consequently minimising their reliance on human intervention. This permits staff to devote extra time to more through-provoking tasks or keep creating while everyone’s asleep.

“All I have to do is make sure jobs are always loading through Fleet Control, which I can do from home or my office,” says Pauwels.

Summing up

The Formlabs Automation Ecosystem offers notable cost reductions and improved productivity for SMEs by leveraging automation to accelerate additive manufacturing processes.

Automation simplifies steps such as part removal, queue management, and printer prepping, resulting in minimised labour hours, more operator flexibility, and an effortless workflow.

Form Auto, Fleet Control, and the High-Volume Resin System all collaborate to make your 3D printing projects more efficient, so you can deliver greater value for your customers.

Find out more

Formlabs has a whitepaper on calculating the ROI for the Formlabs Automation Ecosystem, offering insight into the cost and efficiency savings.

We can also advise on the investment and rollout of AM automation technologies. Call us on 01765 694 007 or email [email protected].