The FX20 transforms manufacturing floors with high-temp engineering materials reinforced with continuous fibre. Continuous fibre reinforcement builds stronger, stiffer, and more durable parts than filled and unfilled plastics by reinforcing a part’s perimeter, select features, or entire layers with carbon fibre.

The FX20 also prints ULTEM™ 9085 – a high-strength, heat-resistant superplastic for custom, robust fixtures in the most demanding industries, including aerospace and defence.

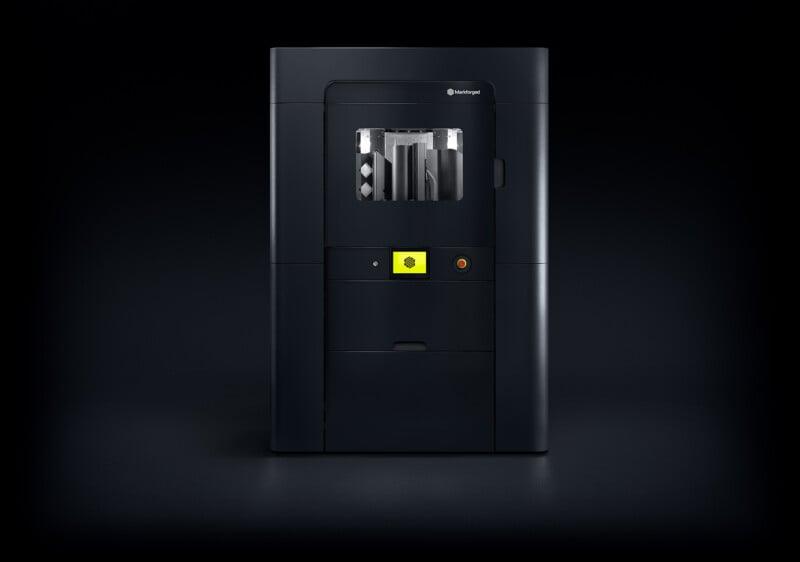

FX20 specs

Build volume

- Width: 525 mm

- Depth: 400 mm

- Height: 400 mm

Print specifications

- Process: Fused filament fabrication and continuous fibre reinforcement

- Layer resolution: 50-250 μm

- Media types: Polymer filament and continuous fibres

- Internal geometry: Closed cell infill with continuous fibre reinforcement

- Print bed: Precision machined aluminium bed

What does it print?

The FX20 primarily prints proprietary materials. The base filament is Onyx, a part-nylon, part-chopped carbon fibre material that has reformulations for fire retardancy and ESD-safe applications.

Vega™ is Markforged’s first engineered high temperature plastic — an ultra high-performance carbon fibre filled PEKK

ULTEM™ 9085 is a third-party-supported filament made from polyetherimide (PEI) thermoplastic material.

Plastics

Fibres

Support materials

Optimise oil and gas operations

Your oil and gas equipment faces harsh environments and chemical exposure. The FX20’s material capabilities, including high-temperature thermoplastics and composite reinforcement, produce parts that withstand these demanding conditions.

The large build volume accommodates substantial components, while The Digital Forge platform and Blacksmith ensure consistent quality across global operations.

SQP Engineering, a Perth-based industrial manufacturer, deployed the FX20 to produce specialised mining equipment parts. Print time dropped from 9 hours to 2.5 hours for their wireline counter covers, with superior surface finish.

The company paired the FX20 with a Metal X system to expand its manufacturing capabilities beyond traditional CNC machining. This enabled growth into the medical, aviation, and agricultural sectors while maintaining competitive pricing and faster turnaround times.

Industrial-grade applications

KST Moschkau transformed its security camera housing production with the FX20. By switching from outsourced CNC aluminium parts to in-house 3D printing, they slashed lead times from weeks to days and reduced costs to one-sixth of original expenses.

The FX20’s large build volume enables three housings per print, while the Onyx material provides durability comparable to aluminium but lighter. The finished products maintain quality standards and are weather-resistant for outdoor deployment.

Transform your aerospace applications

Your aerospace components demand exceptional performance under extreme conditions. The FX20’s ability to print ULTEM™ 9085 Filament with continuous fibre reinforcement delivers parts that combine high strength with low weight.

Onyx FR-A is flame retardant with UL Blue Card certification, and is considered V-0 (self extinguishing) at thicknesses greater than or equal to 3mm. The material has lot-level traceability and can meet FST requirements for aircraft interiors.

The printer’s large 525 mm x 400 mm x 400 mm build volume eliminates the need for assembly for many components while maintaining tight aerospace tolerances.

Accelerate automotive production

The FX20 streamlines automotive manufacturing by printing production-grade parts 8x faster than traditional methods.

Its high-temperature chamber (200°C) ensures optimal layer fusion for components that withstand assembly line demands. The large build volume accommodates multiple parts per print, from custom jigs and fixtures to functional prototypes and end-use parts.

Continuous carbon fibre reinforcement delivers the strength and durability needed for automotive applications while maintaining a lighter weight than most metal components.

Enhance defence capabilities

The FX20’s precision frame and advanced sensor array deliver mission-critical parts with aerospace-grade accuracy.

High-temperature ULTEM™ 9085 paired with continuous carbon fibre creates components that withstand extreme operational conditions.

The large build volume enables rapid production of tactical equipment, vehicle components, and specialized tools that meet rigorous military specifications. Real-time monitoring and closed-loop controls ensure repeatable quality for classified defence applications.

Transform your manufacturing process

With its precision engineering, advanced sensor systems, and robust material capabilities, the FX20 brings industrial-scale composite manufacturing to your factory floor.

The combination of size, speed, and sophisticated technology delivers the next generation of additive manufacturing for your most demanding applications.