Markforged’s Continuous Fibre Reinforcement is a revolution for FFF manufacturing, allowing long-strand composite fibres to be embedded along the load paths for maximum strength approaching metal levels of performance.

How close does it get? Markforged CFR with carbon fibre produces components boasting a strength-to-weight ratio 50% better than 6061 aluminium.

Printing advanced composites like carbon fibre, high-temp fibreglass, and Kevlar as reinforcement is a huge leap forward for the factory floor, enabling the build of products, parts, and rigs that ordinarily involve machining. Markforged’s materials science department also produces proprietary filaments like Vega (a carbon fibre-infused PEKK) and Onyx (a carbon fibre-infused nylon) to further enhance physical properties.

There are several printers on Markforged’s roster to consider – the FX10/FX20 and X Series are pitched at manufacturers, while the Onyx Series and Mark Two are suited to workshops and engineering environments.

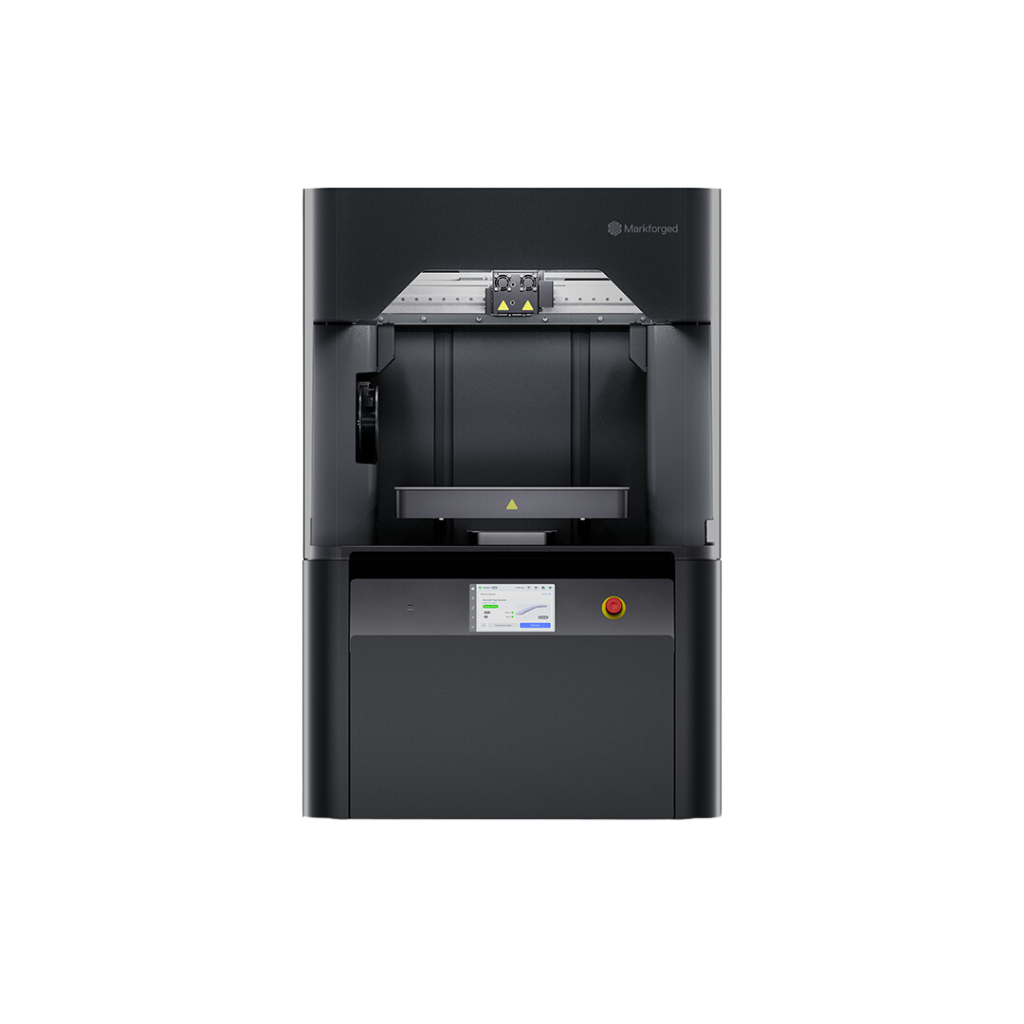

Markforged FX10 and FX20

The FX10 is built for the factory floor with a heated 375mm x 300mm x 300mm build chamber and a patented CFR printing process – the FX20 has a more expansive 525 mm x 400 mm x 400 mm build volume and is the only printer compatible with Markforged Vega filament, formulated for use in the aerospace industry.

The FX20 can print at 200°C and is compatible with ULTEM 9085, supporting reinforcement with fibres like carbon fibre and fibreglass.

To ensure reliable, repeatable accuracy, the FX10 and FX20 incorporate two optical sensing systems – a laser micrometre scans parts during printing, while an upcoming vision module will capture images to optimise printer performance. Together, these sensors verify part quality and give visibility into printer health.

Designed for the demanding environment of the shop floor, the FX10 offers an automated and user-friendly printing experience. Features like automatic spool changeover and print calibration enable continuous production with less human oversight.

Both printers are part of Markforged’s wider digital manufacturing platform, the Digital Forge – this includes the Eiger enterprise-grade central printer control and management software, simulation tools to digitally test parts, and automated inspection options. With this comprehensive solution, manufacturers can set up a digital inventory to print spare parts on-demand instead of tying up capital in physical inventory.

Markforged X7

The Markforged X7 is a top-of-the-line industrial composite printer that produces end-use quality parts with exceptional strength, accuracy, and surface finishes. With its 330 x 270 x 200mm build volume, the X7 produces large format prints that are currently only possible through metal machining and other costly subtractive techniques.

The X7 can print with Nylon or Onyx (ESD/FR) as the core build material, and can reinforce parts with Carbon Fibre, Fibreglass, Kevlar, High Strength and High Temperature Fibreglass and Precise PLA.

At the core of the X7 is Markforged’s CFR technology, reinforcing parts with carbon fibre, fibreglass, and Kevlar strands during printing for metal-like strength and durability. Parts can replace aluminium components and exhibit high stiffness and wear resistance.

The X7 introduces high-precision capabilities unmatched in desktop printing, including 50-micron resolution and an integrated laser scanner for in-process inspection, creating closed-loop control checks dimensional accuracy mid-print down to 1-micron tolerance.

Ease of use is built in with assisted print bed levelling, customised application profiles, remote monitoring tools and intuitive controls through Eiger – Markforged’s integrated software suite for preparing, queuing, and monitoring prints.

Markforged Mark Two

The Mark Two is Markforged’s flagship desktop 3D printer, enabling engineers to print end-use quality parts with exceptional strength.

This CFR technology sets the Mark Two apart, allowing it to produce parts as strong as machined aluminium right from your desktop.

With a 320 x 132 x 154 mm build volume, the industrial-grade Mark Two features a precision-ground composite print bed for accuracy and reliability, and the print resolution ranges from 100-200 microns.

You can print carbon fibre, fibreglass, Kevlar, and the popular Onyx material – a micro carbon-filled nylon with excellent strength.

The whole printer only weighs 35 pounds with a unibody aluminium frame designed for nonstop operation over thousands of print hours, and you get the Eiger software suite – an integrated browser-based solution for printing preparation, management, and monitoring.

With Eiger’s simple CAD import and preparation tools and the Mark Two’s seamless Composite Fibre Reinforcement printing process, going from a 3D model to a finished industrial part is easier than ever.

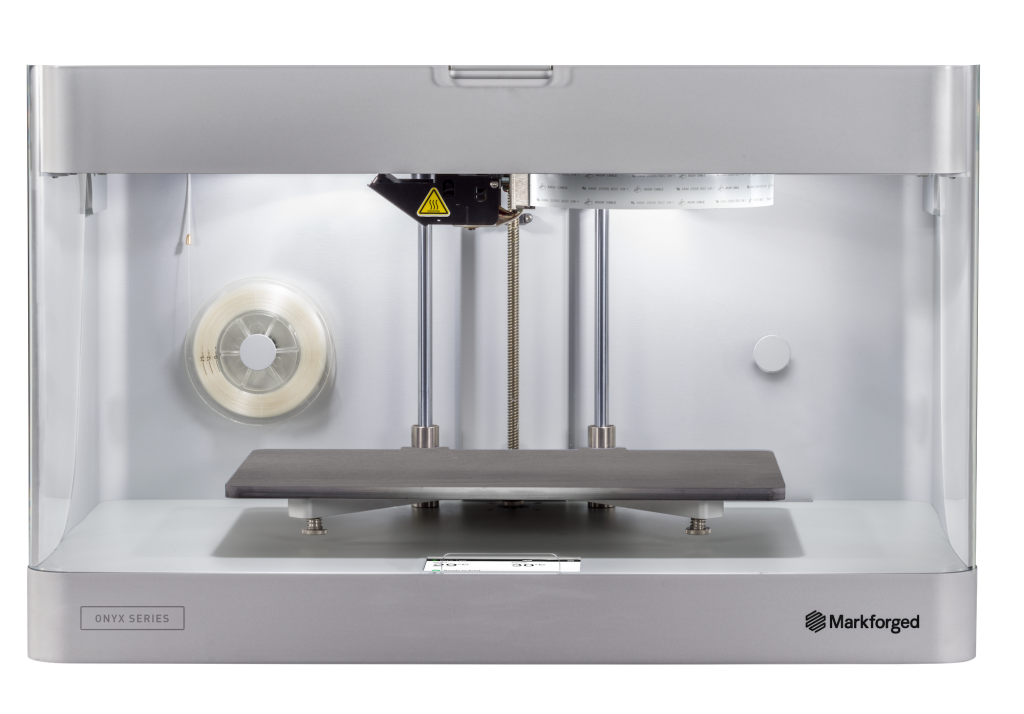

Onyx Series

The Onyx One and Onyx Pro are both industrial-grade fused filament fabrication (FFF) printers from Markforged designed specifically for printing the company’s Onyx micro carbon fibre-filled nylon material.

They share several similarities, including robust all-metal construction, a 320 x 132 x 154 mm build volume, 100-micron layer resolution, and compatibility with Markforged’s Eiger cloud-based printing software. Where the two models differ is the Onyx Pro’s ability to print using Markforged’s fibreglass composite filament in addition to Onyx.

The Onyx Pro’s dual extruders allow switching between Onyx and fibreglass filaments within the same print job, enabling designs with fibreglass only in high-stress regions for optimised mechanical performance.

Additionally, the Onyx Pro introduces printing in 200-micron layers, which doubles print speeds to 400mm/sec with no loss in surface quality.

Limitless applications

With 3D printing, small batches of end-use composite parts can be produced in-house on demand, enabling agile manufacturing with minimal inventories – ideal for industries like motorsports with frequent design changes.

Complex geometries impossible with moulds and machining are also possible with composite 3D printing, enabling performance-driven designs. And despite their strength advantages over standard thermoplastics, composite lattice structures and thinner walls result in lighter-weight components.

Aerospace

Continuous carbon fibre reinforcement enables the 3D printing of lightweight, high-strength components like interior brackets and housings that meet demanding aerospace requirements. Consolidating parts and optimising designs results in weight and cost savings. The latest material for this industry is Vega, a carbon fibre-infused PEKK.

Automotive

Continuous fibre-reinforced components are ideal for durable automotive parts, including tooling, jigs and fixtures, and end-use components like camera mounts and HVAC assemblies. Parts show high strength-to-weight ratios and stability in demanding conditions.

Consumer products

Composite reinforcement allows 3D printing of durable products like protective cases, sporting goods, drone components, and wearable devices.

Industrial

Composite materials enable lightweight, customised end-use parts for robots, production line equipment, assembly tools, and mechanical systems. The materials withstand harsh industrial conditions over long service lifetimes.

Mould making

Reinforced filaments like carbon fibre nylon work well for mould tools and injection moulding aids like jigs. The high stiffness resists deflection under pressure while providing faster, cheaper tooling.

Summing up

Plastics will always have a rightful place in manufacturing, but when it comes to replicating the performance of metal components, even high-performance thermoplastics like PEEK and carbon-fibre-infused ABS-CF fall by the wayside. Markforged CFR dials performance up several levels, creating a high-performance workflow with composites and proprietary materials like Vega. It also brings automated print preparation, monitoring, and control to the party with The Digital Forge, which uses AI to get smarter with every print. The result is an additive manufacturing ecosystem that transforms the factory floor.