Our metal 3D printing service is a game changer for manufacturing. It allows practically any business, big or small, to make ultra-durable metal parts in almost any shape imaginable without waiting months for production machinery or breaking the budget on high costs.

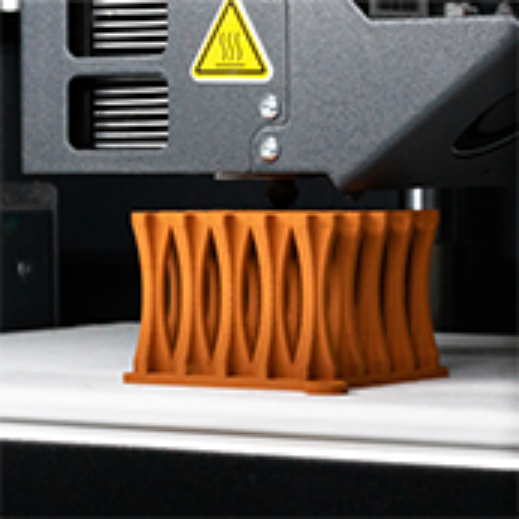

By outsourcing designs to our metal 3D printing specialists, customers get flawless, intricate components crafted with cutting-edge technologies like bound powder extrusion. Parts made this way take days or weeks instead of months thanks to automated, scalable systems that build up components layer-by-layer, practically like magic compared to traditional methods.

Metal 3D Printing Service Technologies

Metal FFF / Bound Powder Extrusion – melts metal-bound plastic filament.

- Printers in this category include the Markforged Metal X and Markforged PX100 and the Ultimaker S5 and Ultimaker S7 with the Metal Expansion Kit.

- It uses a metal-infused filament that has metal particles. Usually, stainless steel, tool steel, copper, or alloy.

- The metal filament feeds into a high-precision FFF printer with a hardened steel nozzle capable of handling printing at high temperatures.

- The printer first heats the chamber and nozzle to high temperatures, typically over 200°C, melting the polymer and allowing the metal particles to fuse. As the material is precisely laid down layer by layer, the melted polymer binds the metal particles in place.

- After printing, the part undergoes debinding to remove the polymer carrier, creating a “green” part composed solely of metal particles.

- The green part then goes into a sintering oven like the Markforged Sinter. The metal particles fuse into dense, rigid, solid metal.

- Additional finishing processes like machining can achieve desired mechanical properties, surface finishes, and tolerances.

- The Markforged PX100 does not require any heating, curing, or drying steps to 3D print metal. This eliminates the need for long warm-up and cool-down cycles between prints, allowing for a very quick turnaround time between builds.

DMLS – uses a laser to melt a metal powder.

- A thin layer of metal powder (usually steel, titanium, aluminium, cobalt-chrome, or nickel alloys) is spread evenly across the build platform by a recoating system at a layer thickness of around 100 microns.

- A high-powered laser then selectively fuses or sinters the powder together in the pattern of the object layer defined in the 3D model file.

- The build platform then lowers by one layer thickness, and a new layer of fresh powder is spread over the previous layer using a recoating arm or roller mechanism.

- Steps 2-3 repeat until the entire 3D object is complete. Unfused powder remains in place to support overhangs and complex geometries.

- Once printing is complete, the excess powder is brushed and blown off. No additional curing is needed.

- Any support structures are removed, and the part may go through some post-processing like sanding, polishing, or infiltration to enhance mechanical properties.

The Benefits of Outsourced Prototyping

Cost Savings

Metal 3D printing services let businesses, artists, designers, and engineers outsource jobs instead of investing in expensive in-house equipment. This eliminates significant capital costs and overheads, directing budgets to parts and products. Users sidestep purchasing industrial printers and dedicate space, staff, and resources to run them.

These services unlock cutting-edge techniques through outside expertise and hardware. Individuals and small teams can finally access advanced methods typically out of financial reach. Larger operations also see funds freed from equipment purchases and toward core priorities.

Production Capacity and Speed

Even large operations can’t match the production firepower of a full-scale metal printing service. While buying 1 or 2 industrial metal printers seems tempting, sheer output demands often overwhelm in-house capacity. By contrast, dedicated printing shops run fleets of the latest equipment specifically sized for volume.

This outsourced prototyping empowers businesses to build at scale, such as 5 parts one week and 50 high-quality components the next, without infrastructure constraints or bottlenecks. For more significant production runs, specialised metal 3D printing services can simultaneously print thousands of metal parts at speeds unattainable on proprietary printers. Their equipment arrays also provide redundancy if any single machine goes offline.

Quality Results

A professional metal 3D printing service brings end-to-end quality control that in-house setups struggle to match. Each metal part undergoes refined handling from start to finish for unmatched consistency.

Before printing begins, trained experts ensure files meet strict tolerances, optimising builds for reliable output. Industrial-scale equipment then uses preferred techniques like selective laser melting to construct components with minimal defects.

Parts can then proceed through supplemental techniques on your side like heat-treating, finishing, and meticulous inspection to verify full compliance with ISO standards or industry certifications critical for aerospace, defence, medical, and automotive customers.