PLA is the most suitable material when you require strength, stiffness, and low costs, in builds that aren’t exposed to heat or sustained mechanical stress – think decorative models, prototypes, jigs, and educational projects.

Another advantage to printing PLA is that it captures excellent detail and dimension accuracy, tolerances of +/-0.1mm or better are achievable. Those characteristics mean that, barring any issues, your builds will match your designs in software.

PLA is also a green plastic, as its formulation uses organic ingredients without petrochemicals. Additionally, it is recyclable and biodegradable in the correct facilities and emits fewer particulates than other plastics during printing.

There’s plenty more to unpack, so join us below to learn more about PLA.

Core material

PLA comes from plants rather than oil. Cornstarch and sugarcane transform into printing filaments after fermentation creates lactic acid polymers. Printers melt these polymers between 190-220°C, laying down layers which cool rapidly into solid models.

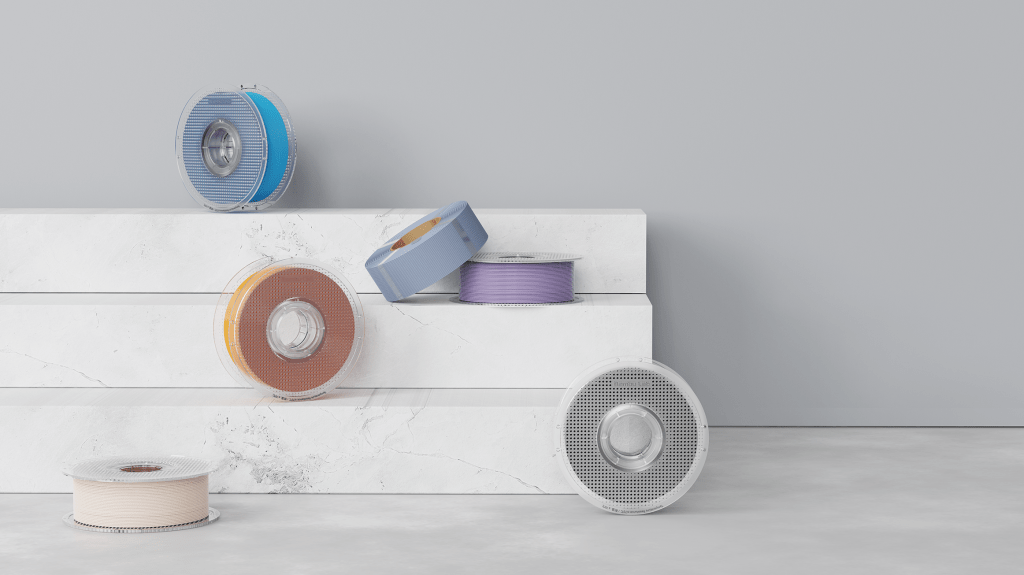

Shop now: PLA Filament (strong, high-quality, affordable)

Every fused filament fabrication (FFF) printer supports PLA due to its low extrusion temperature and no hard requirement for a heated bed (although 50-60°C is optimal for improving adhesion and reducing lifting risk).

Printing behaviour

PLA is incredibly accessible to newcomers due to its wide temperature range and minimal setup requirements. Unlike demanding materials that require enclosures or exotic surfaces, PLA sticks reliably on standard beds with simple paper glue or bare glass.

Printing happens consistently at modest speeds without dramatic setting adjustments between brands or colours. Layer bonds form well without excessive temperature demands, creating solid models straight off the print bed without advanced techniques or equipment.

Workshop handling

Keep spools dry in sealed containers with silica packets. Moisture ruins PLA because hydrolysis causes bubbles and weak spots throughout prints. Grinding sounds during extrusion indicate wet filament needing drying before quality prints become possible.

The Polymaker PolyDryer is highly recommended for professionals to keep PLA spools dry. It maintains a sealed environment with humidity settings.

Modified varieties

PLA comes in toughened variants addressing the brittleness issues standard PLA suffers from. PLA+ formulations include impact modifiers, increasing durability without significantly changing print temperatures or speeds.

Carbon fibre PLA (PLA-CF) adds significant stiffness and dimensional stability while slightly reducing layer adhesion. CF variants require hardened steel nozzles since standard brass wears quickly from carbon fibres flowing past metal surfaces during printing.

Mechanical limitations

Due to layer adhesion properties, strength varies dramatically between vertical and horizontal orientations. Parts break more easily between layers than across them, requiring design consideration for load-bearing applications and which orientation to print the model in for best strength in application.

Heat deformation starts around 60°C, making functional parts unsuitable for anything experiencing significant thermal stress during use.

Support considerations

PLA models requiring supports benefit from using the same-material structures rather than dual-extrusion solutions. PLA supports break away or can be snipped, leaving minimal scarring compared with other materials.

Orientation choices and geometry modifications can eliminate some support requirements. Alternatively, thicker walls and chamfers on the undersides of overhangs allow better layer adhesion without complete supports.

Finishing techniques

PLA prints often show visible layer lines requiring post-processing for professional appearances. Printing at a fine resolution to helps to minimise layer line visibility straight off the printer. However, if further processing is needed wet sanding yields superior results to dry methods, starting at 220 grit and working upward while keeping surfaces damp.

Acetone proves ineffective, unlike with ABS, so try ethyl acetate for chemical smoothing when sanding seems impractical. Heat guns carefully soften surface details without structural damage, creating glossy finishes on complex geometries.

Troubleshooting prints

Nozzle clogs happen when foreign particles block tiny openings. Depending on the severity, cold pulls or nozzle replacement are required.

Stringing between separate sections indicates that the print nozzle temperature may be too high, or possibly that the retraction speed and distance settings need adjustment. Curling edges signal cooling issues solved with adjusted fan speeds or print temperatures.

Recycling possibilities

PLA waste is recyclable in industrial composting facilities that accept bioplastics rather than standard recycling streams. Most residential recycling programs cannot process PLA properly, leading to contamination issues.

Check with local waste management services about PLA collection points in your area. Remember: PLA only biodegrades under industrial conditions, despite being made from renewable resources – so don’t chuck it in your home composting bin!

Comparing materials

ABS offers better heat resistance but produces fumes and warps significantly without enclosures. PETG combines PLA’s ease with improved durability, standing between the two materials in difficulty.

TPU flexes without breaking, complementing rigid PLA models when projects require different mechanical properties (PLA is stiff, while TPU is flexible). For instance, you could print a PLA smartphone case with a TPU edge.