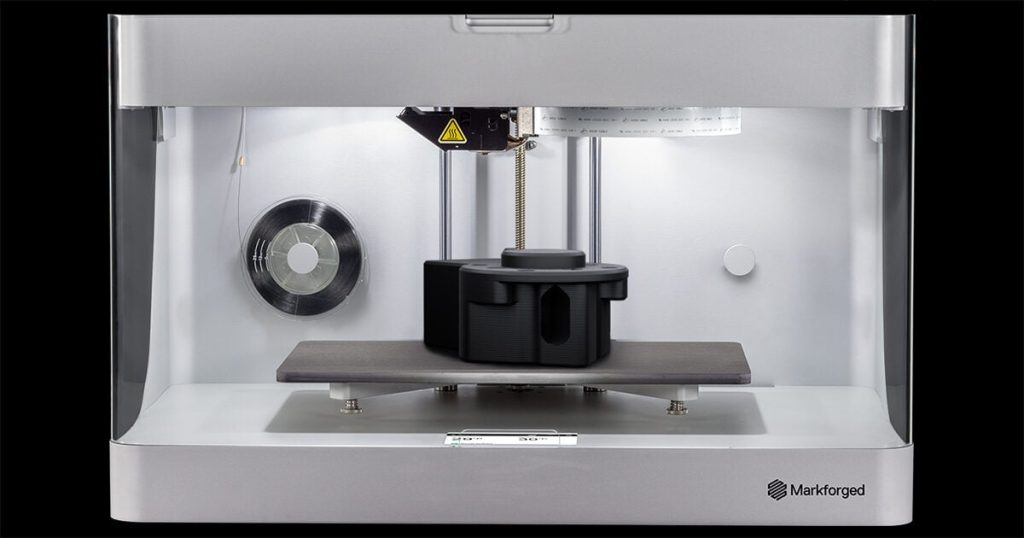

A 3D printer like the Markforged Mark Two, capable of printing nylon and Onyx parts reinforced with composites such as carbon fibre, fibreglass, or Kevlar, is a financially sensible investment for many commercial and industrial applications.

The Markforged Mark Two allows for quick iteration and testing of prototypes using strong, reinforced materials, reducing lead times and costs compared to traditional methods.

Building lightweight parts or customised components is cost-effective, whereas conventional manufacturing, like CNC machining, is expensive.

Printing durable tooling, fixtures, and functional end-use parts on-demand streamlines manufacturing processes and enables part consolidation, cutting assembly costs.

Industries like manufacturing, aerospace, and automotive can benefit from producing lightweight yet robust parts with ideal strength-to-weight ratios without waiting on suppliers to do their part in the process.

Vogel Druck

Vogel Druck und Medienservice GmbH, a German magazine and catalogue producer, is a prime example of a company that benefits from Markforged 3D printers.

They use 3D printers to build components for their printing and assembly machines, eliminating suppliers and bottlenecks associated with old, obsolete parts.

Jörg Kuchenmeister, Managing Director of Vogel Druck, and Stefan Kemmer, Quality Assurance Lead, invested in Markforged 3D printing technology to solve the enormous cost of sourcing parts for older machines, where one part might cost thousands of Euros and not be available again due to low stock.

The Mark Two started out as a test case to see if it could produce functional parts, but shortly after the start of a shift, an original machine part failed. Production ground to a halt, and the Vogel Druck needed a rapid solution.

Stefan designed the failed part in Fusion 360 CAD software and, within hours, had a working component in the software. He sent it to print through Eiger, and after four hours, the 3D-printed component was ready for action.

It was installed, and the machine restarted – all within the same shift.

That success saved thousands of Euros in lost revenue from machine downtime, just from one failure. Over time, the Vogel Druck team replaced more components after realising the 3D-printed ones performed better and lasted longer.

Now, they manufacture:

- Machine spare parts.

- New jigs and mounts to improve machines.

Getting down to brass tacks

The Markforged Mark Two costs around £18,000, including VAT, yet Vogel Druck saved approximately £17,000 in 12 months of 3D printing, giving them a near 100% return on investment in a little over a year.

For example, a part that often fails is a lifting finger that costs £450 to replace. The Markforged Mark Two prints a replacement for only £3.50. With around 30 to 40 finger replacements per year, the savings soon rack up.

The savings were so impressive that Vogel Druck invested in another Mark Two printer and scaled production, saving circa £70,000 after just nine months.

And the Markforged Mark Two isn’t the only 3D printer that can produce durable end-use parts – the Markforged Metal X with the Wash 1 and Sinter 2 is a complete metal FFF 3D printing ecosystem, giving you the 3D printer, wash station, and furnace to produce complete metal components for end use.