For over 50 years, CNC machining has dominated high-precision manufacturing with its lightning-fast metal cutting and microscopic accuracy. It’s been the undisputed champ for industries like aerospace that demand the utmost quality. But in the last few decades, 3D printing has stepped up.

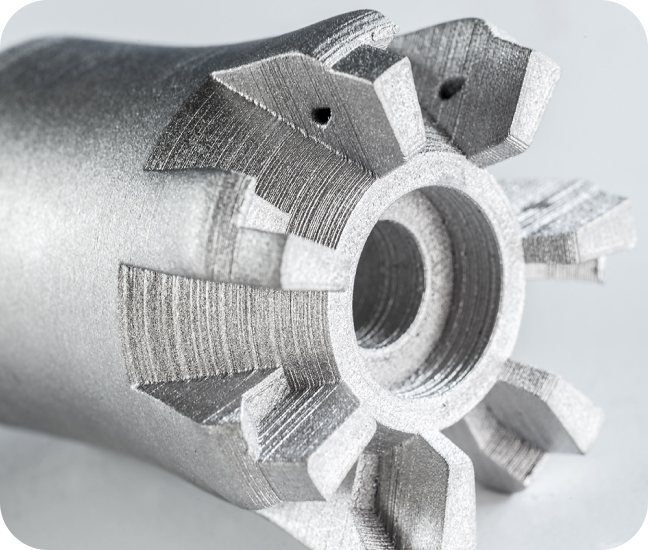

At first, 3D printers struggled to match CNC’s insane precision. But improvements in materials and printers like the Metal X mean 3D printing now produces parts rivalling CNC quality. 3D printing’s low barrier to entry has opened affordable, low-volume precision manufacturing, letting engineers quickly try wild new geometries that are just not possible with CNC subtraction.

3D printing hasn’t yet dethroned CNC as the heavyweight champ. But it has earned its spot in precision manufacturing, especially for fast prototyping, tooling, and short runs. By combining these former rivals, manufacturers gain unbelievable flexibility and efficiency for turning cutting-edge designs into precision-engineered parts. CNC and 3D printing can co-exist to take manufacturing capabilities to new levels.

Milling Speed vs. Print Speed

When it comes to pure machining speed, CNC is hard to beat. Those wicked fast spinning cutters carve through metal like a hot knife through butter, churning out parts lightning fast. A basic bracket off a CNC mill might take 30 minutes from start to finish.

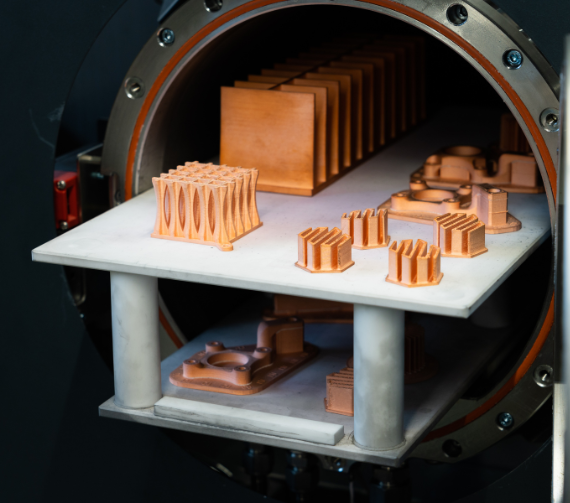

3D printing, on the other hand, lays down material a fraction of a mm at a time. That bracket could take 8+ hours to print up layer by layer, then a few more to wash and sinter with something like the Markforged Wash 1 and Sinter-2 for the Metal X. There’s no question CNC wins for pure build speed.

But here’s the thing – 3D printing speeds up other process aspects. With CNC, machinists must manually program the tool paths, set up the machine, fixture the part, and change tools…it takes serious time.

With 3D printing, you fire over a CAD file and let the software automatically slice up the toolpaths. Minimal setup, no fixtures needed, and you’re off to the races. The printer just keeps laying down material until the part’s built.

So, while layer-by-layer printing is slower, the overall design to finished part workflow can be faster with 3D printing. Engineers can tinker with a design and have a new iteration printing overnight, accelerating innovation and ultimately getting products to market faster.

And you don’t need a specialist metal printer to do it – the UltiMaker S5 has a Metal Expansion Kit, turning your plastic FFF 3D printer into a metal one.

Closing the Accuracy Gap

For a long time, 3D printing’s accuracy and surface finish trailed far behind CNC machining. Early plastic parts were prone to layer lines and poor dimensional accuracy. But recent advances have started to close the gap.

With precision extrusion systems and tightly calibrated build plates, industrial 3D printers can now achieve tolerances down to +/- 0.005 inches—right in the ballpark of CNC machining. The materials going into these printers have advanced, reducing layer lines and enabling smoother finishes.

Specific post-processing techniques like vapour smoothing can even further improve surface finish. And because 3D printing constructs parts layer-by-layer, it minimises internal stresses that can lead to part warpage, resulting in uniform material properties approaching those of machined components.

Lower Costs for Lower Volumes

The essential advantage of 3D printing is its low costs for short-run production. With CNC machining, the high upfront costs for programming, setup, fixturing and tooling get amortised over the entire production batch, making per-part costs high for small batches.

With 3D printing, programming is fast and easy. Minimal fixture and tooling are required. So, the per-part cost stays relatively constant regardless of volume.

This opens affordable low-volume precision manufacturing to industries like aerospace, which can now economically produce complex parts via 3D printing. Small batches of 50-100 units can be cost-effective.

For larger volumes, CNC machining still reigns supreme for metal parts. But metal additive manufacturing has carved out an important niche in precision engineering for prototypes, tooling, and short-run production.

The Hybrid Approach

Instead of looking at CNC and 3D printing as competing technologies, innovative manufacturers combine them for the best of both worlds.

Engineers now regularly use 3D printing to iterate prototypes of new designs overnight quickly. No programming or fixturing is needed – fire up the CAD file and let it rip. This accelerated design process lets you try out more concepts upfront before settling on a final design to move to machined production.

For existing parts, 3D printing is ideal for on-demand production of spare parts, jigs, fixtures – anything needed to reduce downtime. No need to stockpile parts or wait days for a machine shop – print what you need when you need it.

3D printing also opens the door to wild new geometries like lattice structures and conformal cooling channels that cannot be CNC machined. Engineers are embedding these high-performance 3D printed structures into traditionally manufactured parts to shed weight and boost performance.