The Markforged Metal X offers an accessible and safe alternative to traditional powder-based metal printing and a complementary process to machining.

Using bound powder extrusion technology, the Metal X enables the production of complex metal parts in materials ranging from stainless steel to copper without the hazards and costs associated with loose metal powders.

Whether you’re prototyping or producing end-use components, the Metal X provides a streamlined workflow from CAD to finished part. It complements existing machine shop capabilities while opening new possibilities for complex geometries and rapid iteration.

Join us below to discover innovative industry applications for the Metal X.

Revolutionising oil and gas manufacturing

At Dixie Iron Works, the Markforged Metal X transformed their approach to producing low-volume parts and prototypes.

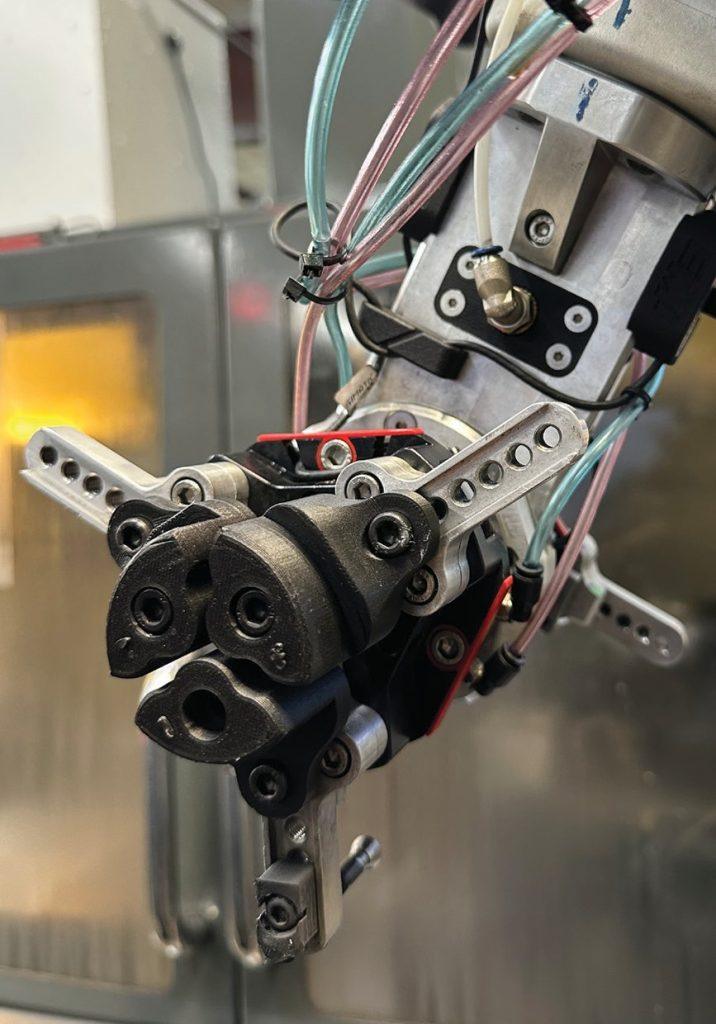

grippers printed in Onyx

Rather than tying up CNC machines for intricate setups on small production runs, their team now uses the Metal X to print components on demand. One notable success was reimagining a dart check valve stop, which was previously expensive to machine or cast.

By redesigning for additive manufacturing, they reduced production costs from $20-30 to just $5 in material costs while upgrading to corrosion-resistant 17-4PH stainless steel.

The technology also enabled them to produce wear-resistant end-of-arm tooling for industrial automation with complex geometries that would be challenging to machine.

Advancing educational innovation

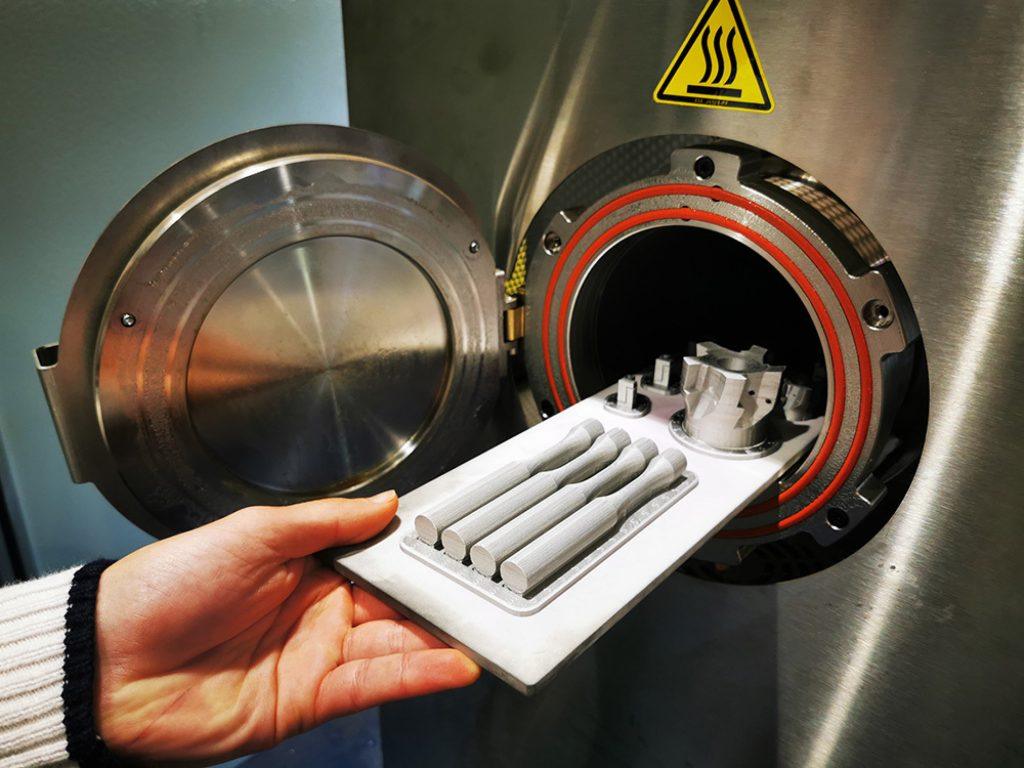

Spain’s Goierri Eskola Technical Institution integrated the Markforged Metal X into their advanced manufacturing curriculum and research programs.

The system’s ease of use and accessibility made it ideal for training future engineers while enabling participation in funded research projects.

In one European project, they successfully produced a tool with internal cooling channels, comparing the results between SLM and Metal X technologies using 17-4PH stainless steel and H13 tool steel. Despite working with parts over 1kg, outside typical design parameters, the results exceeded expectations.

Preserving automotive history

RPG Industries leveraged the Markforged Metal X to solve a unique challenge in classic car restoration.

When tasked with replacing an irreplaceable 1930s carburettor part, they first prototyped in composite materials before producing the final component in 17-4PH stainless steel.

The ability to reverse engineer and reproduce this intricate part, which would have been prohibitively expensive to machine, demonstrated the Metal X’s value for low-volume, high-complexity components.

The successful restoration highlighted how the system can bridge historical manufacturing gaps while maintaining original part aesthetics.

Accelerating medical device development

Shukla Medical adopted the Markforged Metal X to streamline its prototyping process for orthopaedic surgical tools.

Previously reliant on CNC machining or third-party services, it now rapidly iterates designs in-house using the same 17-4PH stainless steel as its final products.

This capability allows surgeons to evaluate functional prototypes sooner, significantly reducing their product development cycle and maintaining their competitive edge in the medical device market.

The workflow combines initial prototyping in composite materials followed by metal iterations, enabling faster design validation while controlling costs.

It has proven particularly valuable for their time-sensitive surgical tool development, where every minute saved in the operating room translates to significant value for healthcare providers.

Pioneering EDM applications

The University of Las Palmas de Gran Canaria deployed the Markforged Metal X for groundbreaking research in EDM electrode production.

Their studies demonstrated that 3D-printed copper electrodes could achieve material removal rates comparable to conventional electrodes, opening new possibilities for manufacturing complex electrode geometries.

This innovation provides a cost-effective alternative for producing intricate EDM tooling while advancing academic understanding of metal additive manufacturing processes.

Their research validated the technology through comprehensive testing, including density, electrical conductivity, and X-ray energy-dispersive spectroscopy analysis.

A cohesive experience with the Digital Forge

The Digital Forge unifies Markforged’s cloud-based software, advanced materials, and industrial 3D printers into a comprehensive manufacturing platform.

You can manage all additive workflows directly on your factory floor through the secure Eiger interface, producing reliable parts on demand.

The platform combines continuous fibre reinforcement technology with metal 3D printers that don’t require extensive training or safety equipment.

Built-in quality control features like micron-level laser inspection ensure accuracy, while AI-powered fleet learning continuously improves performance.

From prototyping to production, the Digital Forge helps transform operations, strengthen supply chains, and drive innovation across composite and metal applications – all through a single enterprise-ready platform.