3D Printing Props, How AM Supports the Creative Process in Film

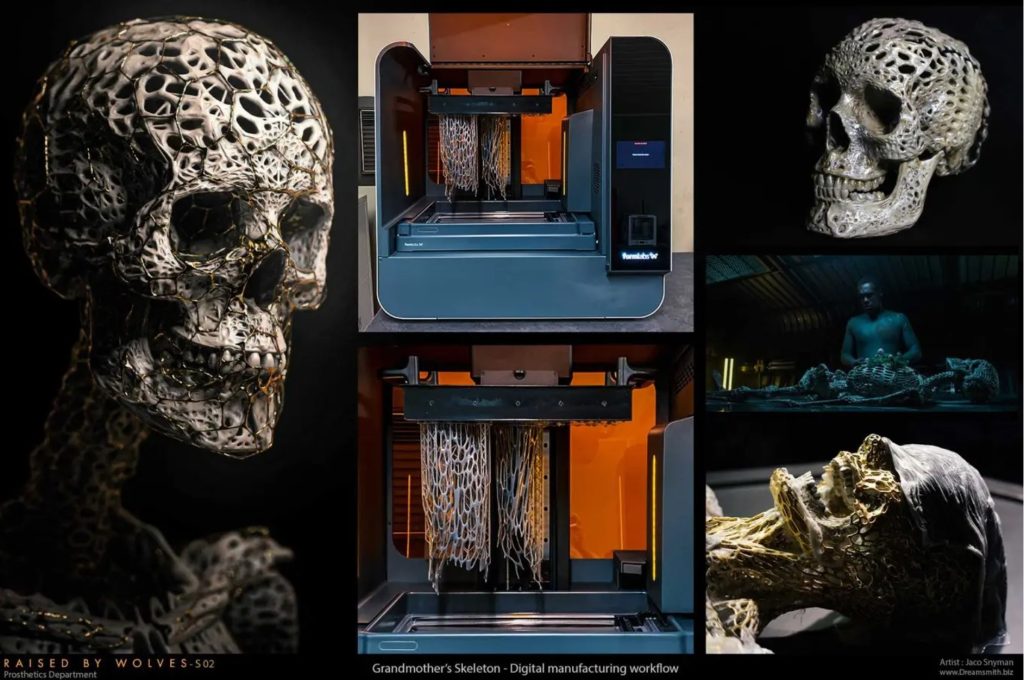

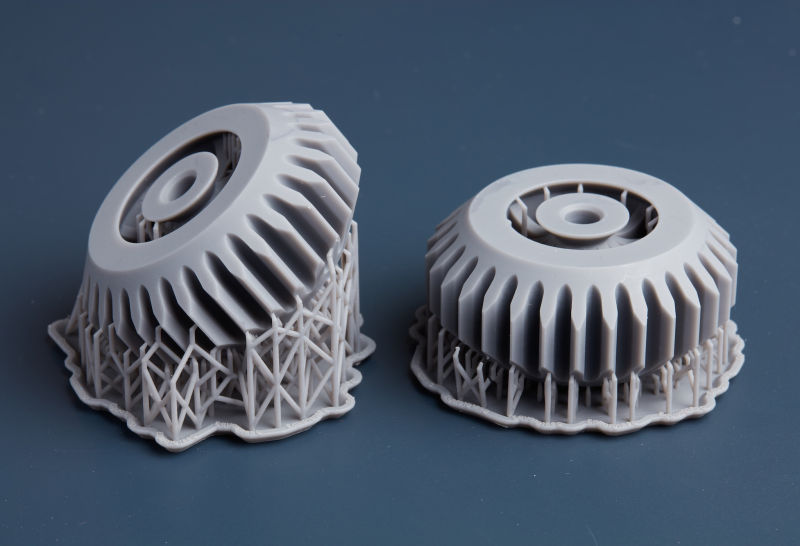

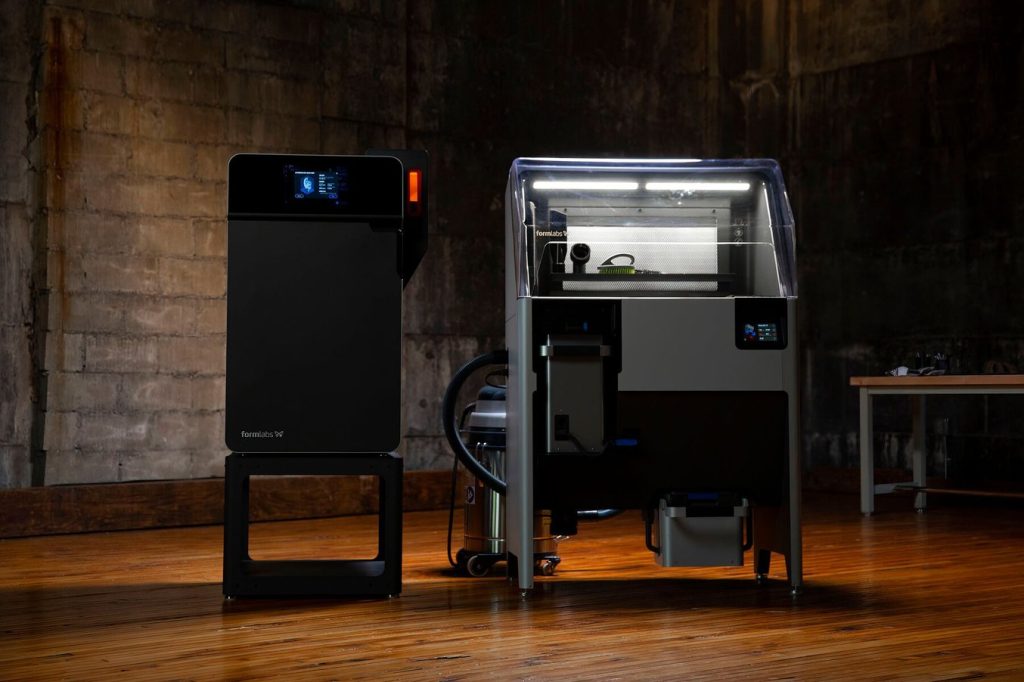

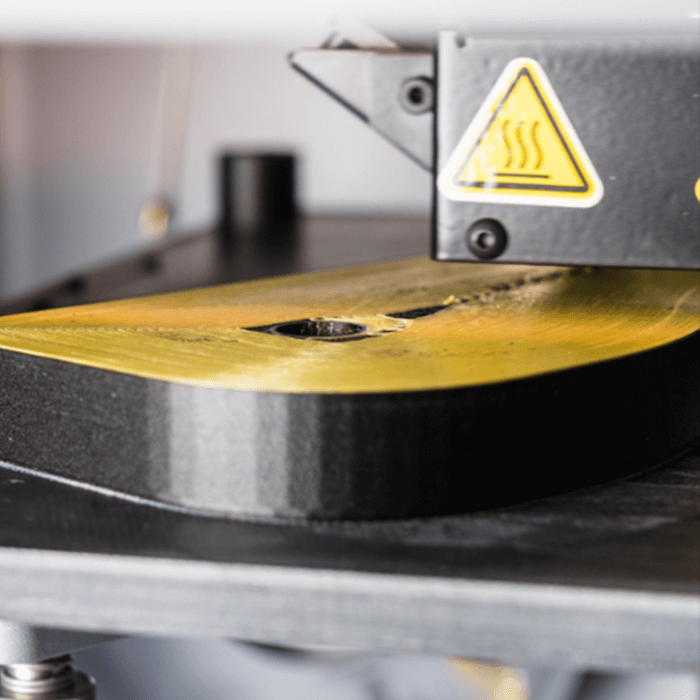

Without the artistry of prop masters, some of Hollywood’s most memorable films, like Guardians of the Galaxy, Star Wars, and Back to the Future, would lack the dazzling visual effects that make them so iconic. Prop-making takes skill, imagination, and creativity, all under the constant pressure of deadlines and resource

3D Printing Props, How AM Supports the Creative Process in Film Read More »