Support materials are the cornerstone of advanced FFF, SLA, and DLP 3D printing, providing stability and strength to parts during printing and preventing part deformation and collapse.

They are also beneficial in attaching a part to the print bed and ensuring that it remains fixed to the main body of the printed part, and can function as heat dissipators in processes involving high temperatures, such as metal 3D printing, where supports can draw heat away from the part to reduce stress.

Supports are implemented in parts with intricate design features like overhangs, holes, and bridges, as they are more likely to collapse without support.

What is 3D support material?

3D support material is a low-density structure that supports the parts of a model that are prone to failure, such as overhangs.

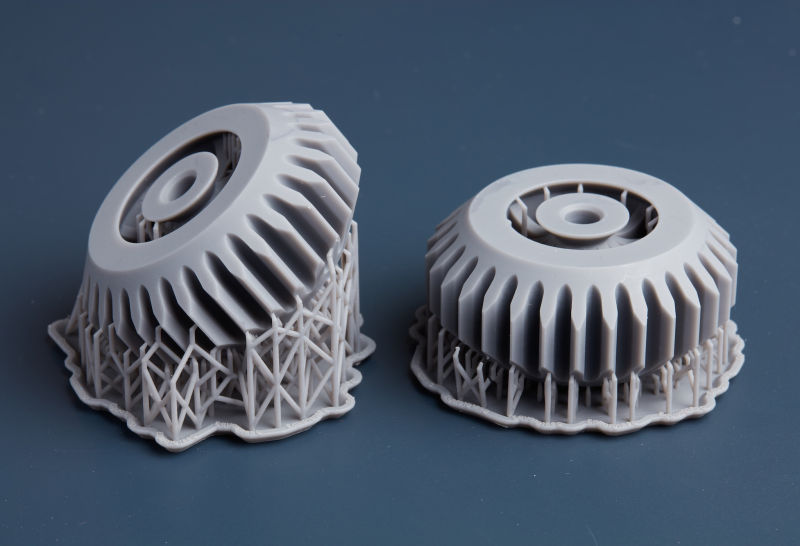

The material is printed in a low-density format to ensure it is easily removable from the model when the project is complete.

SLA and DLP 3D printers use the build material for support structures, using the same resin for supports as the build.

FFF/FDM 3D printers can print a secondary material, usually HIPS, PVA, Ultimaker Breakaway or BVOH:

- HIPS dissolves in limonene and is used as a support structure for ABS and other high-temperature filaments like PEEK.

- PVA dissolves in water and is used when printing at low temperatures, providing good adhesion with PLA and CPE.

- Breakaway is a snappable support material ideal for moisture-sensitive build materials and most standard plastics, including PLA, PETG, ABS, CPE, and Nylon.

- BVOH is a water-soluble filament, compatible with PLA, PRO1, ABS, PA and PAHT CF15.

- ESM-10 is a 3DGence material designed for printing alongside PEEK, a high-temp engineering thermoplastic. It also supports ABS.

When do you need support structures?

Technologies that require support include SLA, DLP, and FFF when the geometry of designs pushes the limits of printability.

Note that some technologies, such as SLS and binder jetting, do not require support due to the unfused powder providing the support structure.

With SLA 3D printers like the Formlabs Form 3+, supports are necessary for structural stability during 3D printing. They can be quickly generated by PreForm or added manually to create more complex structures.

While it is sometimes possible to print simple shapes directly on the build platform with an SLA printer, self-supporting geometries are limited.

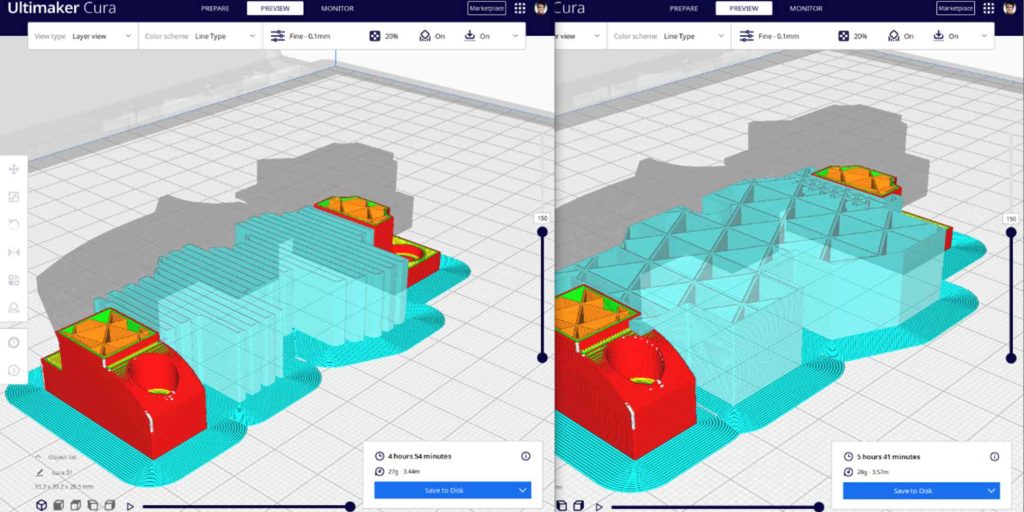

FFF 3D printers like the Ultimaker S5 offer more leeway with support structures, with FFF printed parts being self-supporting up to 45 degrees with optimised print temperatures. You can also use bridging with FFF printers – a technique that involves stretching hot material between two points of a 3D-printed object. You do not typically need support when bridging materials within a 10mm gap.

When bridging is not possible, support structures are necessary. As a rule, support material should be added to ensure printability if the model is complex or has irregular sections. Similarly, if the model has an overhang or hollow structure, it should be included to ensure it prints correctly.

Note that adding support structures to models is primarily automated in software, with Ultimaker Cura, Formlabs PreForm, Markforged Eiger, and most other software offering the option to auto-generate supports for most parts. You can also add supports manually in software if your model requires them.

How to remove 3D support material

With SLA and DLP 3D prints, removing supports after UV curing is best because exposure to light and heat without structural support can warp them.

You can remove supports from SLA/DLP prints with flush cutters and then sand marks and bumps left by supports during finishing.

For delicate parts, ese a hobby knife, scalpel, or other sharp tool to separate supports.

Note that the Formlabs Form 3+, Form 3B+, and Form 3L use proprietary Low Force Stereolithography (LFS) technology, significantly reducing peel forces and producing light-touch supports that snap away cleanly.

Simply put, you do not need to cut any supports away with a new Formlabs LFS 3D printer – supports snap away without any tools.

With FFF supports, the best removal method depends on whether the support material is a breakaway or soluble one.

For breakaway materials like Ultimaker Breakaway and ABS, you can snap supports by twisting the model or using flush cutters.

For water-soluble supports made from PVA and BVOH, submerge models in warm water (around 40°C) and gently stir the water to agitate. Note that BVOH dissolves significantly quicker than PVA in most cases.

You can also use the Ultimaker PVA Removal Station to remove PVA supports efficiently.

For HIPS, you need a chemical called limonene, which acts as a solvent, softening the material and eventually dissolving it. You should submerge your model long enough to soften the supports and remove them manually.

Note that overexposure to limonene can disrupt the interlayer adhesion of some ABS and ASA filaments. So, it is best used as a support softener.

Another option is acetone, which will melt HIPS almost instantaneously but dissolve the topmost layer of ABS, smoothing it. While this reduces visible layer lines, if you want to smooth parts, it is best to use a vapour smoothing unit for a controlled process.

Find out more

To find out more about support materials in 3D printing, call us on 01765 694 007 or email [email protected].

Book an appointment with Elaine

Book an appointment with Elaine

Top image credit: Formlabs.