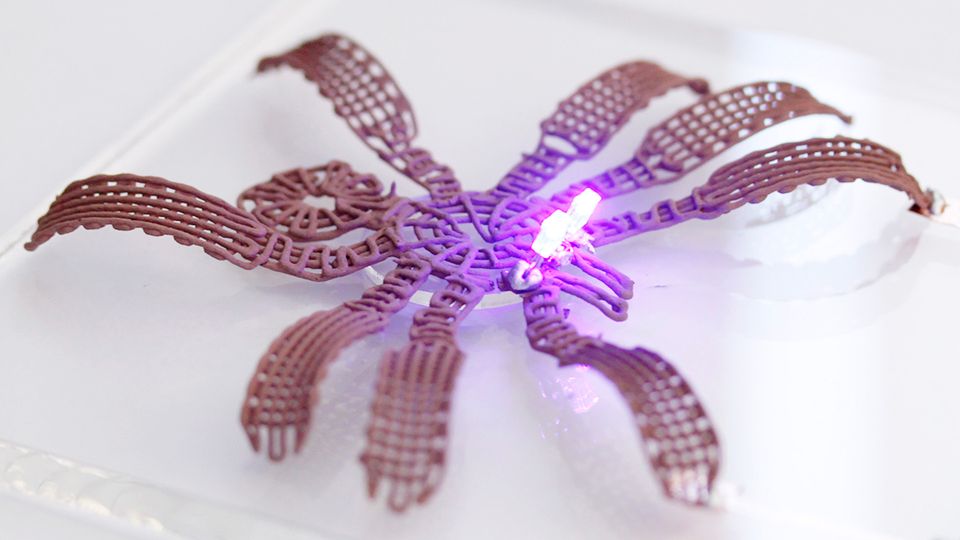

Revolutionising Automation with Electronics-Free Soft Robotics Gripper

Automation has become an integral part of various industries, from manufacturing to healthcare, as it allows for increased efficiency and precision in tasks. Traditional grippers have been used for automation purposes; however, they have limitations when it comes to handling delicate objects or adapting to irregular shapes. This is where soft robotics grippers come

Revolutionising Automation with Electronics-Free Soft Robotics Gripper Read More »