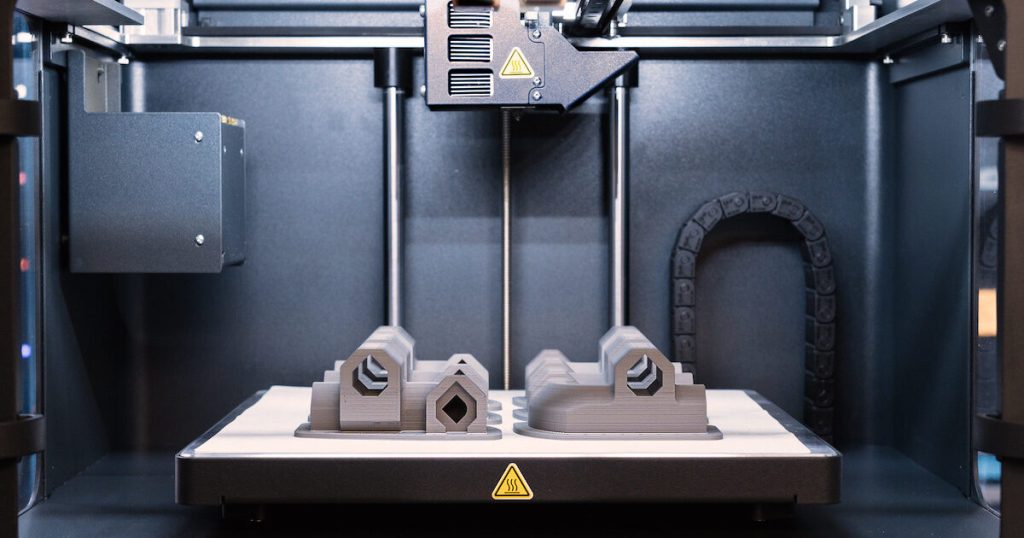

The axes of a 3D printer, typically referred to as the X, Y, and Z axes, along with their respective guides, are fundamental to the machine’s operation. They are responsible for the precise movements that the printer head makes to create the 3D printed object layer by layer. As such, regularly checking and maintaining these components is crucial for ensuring the accuracy and quality of your 3D prints.

- Belt tension: The X and Y axes are typically controlled by special belts that need to have the correct tension to move accurately. If these belts are too loose, the printer head may not move accurately, leading to misaligned layers. Conversely, if the belts are too tight, they may wear out more quickly and could even cause the motor to skip steps. It’s advisable to check the belt tension regularly and adjust as necessary. The correct tension is achieved when you can slightly twist the belt to about 90 degrees with moderate force.

- Lubrication: The Z-axis is usually guided by a lead screw that needs regular lubrication to work smoothly. The X and Y axes might also require lubrication, depending on the printer’s design. Use a non-staining PTFE-based lubricant for this purpose and make sure to clean the rods or screws before applying a new layer of lubricant.

- Cleanliness: Dust and debris can accumulate on the rods and screws that guide the printer’s axes, this can cause problems by creating excess friction, thereby hindering the smooth movement of the components. For this reason, make sure to clean these parts regularly with a dry, lint-free cloth.

- Alignment: The correct alignment of the axes is also crucial for accurate 3D printing. If the X and Y axes are not perfectly perpendicular, your prints may come out skewed. Similarly, if the Z-axis is not perfectly vertical, the layers of your print may not align properly. So it’s important to regularly check the alignment of the axes and adjust if necessary.

- Bearing and Bushing Inspection: The moving parts of the 3D printer often use bearings and bushings. Over time, these can wear out, leading to sloppy movements and less precise prints. Regularly inspect these parts for wear and replace them if necessary.

Checking and maintaining the axes and guides of your 3D printer regularly can go a long way towards ensuring that your machine operates smoothly, accurately, and produces high-quality prints for years to come.