In a groundbreaking discovery, researchers at North Carolina State University, Northwestern Polytechnical University, and Tianjin University have developed a highly conductive metallic gel that is capable of 3D printing solid metal objects at room temperature, revolutionising the concept of four-dimensional (4D) printing.

North Carolina State University. Amongst the 3 teams of researchers who have made the 4D printing breakthrough.

Traditionally, 3D printing involves creating an object layer by layer from a digital design, using a wide range of possible materials. Now, the researchers have pushed the boundaries of this technology by introducing the concept of “4D printing” – where the additional “fourth dimension” refers to changes in the fully printed 3D object over time in response to external factors.

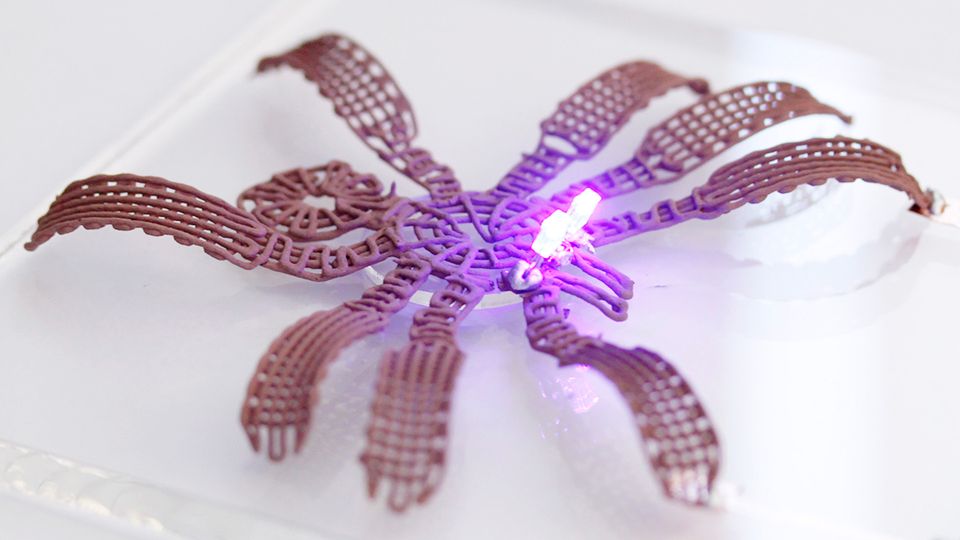

The 4D aspect of the new metallic gel is that it can print objects that change shape depending on its drying temperature. At room temperature, the parts will retain their shape after being printed, but when heated up, their shape changes. This introduces a dynamic element into the otherwise static process of 3D printing.

To create this metallic gel, the researchers begin with a solution of micron-scale copper particles suspended in water. A small amount of indium-gallium alloy, which remains liquid at room temperature, is then added to the mixture. As these components are stirred together, they adhere to each other which forms a conductive metallic gel network within the aqueous solution. The resulting gel, which can retain its shape after printing (depending on temperature), can be dispensed through a standard 3D printing nozzle, marking a significant breakthrough in 3D printing technology.

One of the most exciting aspects of this new development is the object’s potential transformation during the drying process. If the print is allowed to dry naturally at room temperature, it retains its shape while solidifying further. But, if the researchers apply heat during the drying phase, the alignment of the particles within the material and the pattern of the printed object influences how the material dries and therefore deforms.

A metallic spider. Printed at room temperature using the metallic gel. It was then assembled and solidified into its final 3D shape via 4D printing. Credit: Michael Dickey / North Carolina State University.

But this heat-induced transformation isn’t random. Instead, it’s a controllable, predictable process that can be utilised for design purposes. For example, if one prints a cylindrical object and applies heat during drying, the sides contract more than the top and bottom. By controlling the pattern of the printed object and the amount of heat applied during drying, researchers can essentially “programme” the objects to change shape in a specific way over time, hence the reference to the “fourth dimension” of time.

In addition to its transformative properties, the metallic gel is remarkably conductive. The gel can print objects that contain as much as 97.5% metal, which, while not as conductive as conventional copper wire, is far more conductive than anything else that can be 3D printed at room temperature.

This innovation has far-reaching implications for the future of additive manufacturing and technology. The researchers are excited to explore its potential applications and collaborate with industry partners to push the frontiers of 3D, and 4D, printing technology.

And this is just the beginning. The potential applications for such a technology are vast and exciting, ranging from electronics manufacturing to medical devices. This new frontier of 4D printing with metallic gels might well shape the future of additive manufacturing.

Readers interested in the researchers’ original paper may find it here.