The Power of 3D Printing: Forging the Future with Superalloys

In the rapidly evolving world of additive manufacturing and technology, one thing remains constant: our relentless pursuit for stronger, lighter, more efficient materials. As 3D printing continues to grow and develop, we at Additive-X continue to be amazed by the new possibilities that are being explored by researchers across the world. A recent discovery is the creation of superalloys that have the potential to redefine our industries and the way we operate.

The Superalloy Revolution

Recently, researchers led by Andrew Kustas at Sandia National Laboratories in Albuquerque, New Mexico, have managed to 3D print a new high-performance metal alloy, which they term a ‘superalloy’. This incredible material comprises a blend of six elements – 42% aluminium, 25% titanium, 13% niobium, 8% zirconium, 8% molybdenum, and 4% tantalum – which results in a substance that is both stronger and lighter than conventional materials, as well as being incredibly heat resistant.

Superalloys have always been sought after, especially in industries such as aerospace, automotive, and power generation, where materials must withstand high temperatures and stress whilst maintaining lightness for efficiency. But the issue with traditional superalloys, primarily based on nickel and cobalt, is their performance degradation under extreme heat. Modern superalloys, however, can operate successfully at much higher fractions of their melting points.

With the advent of these new superalloys, there’s potential to boost the efficiency of turbines in power plants, which themselves account for around 73% of worldwide electricity generation. More efficient turbines mean greater energy production and reduced wastage, both of which contribute to increased sustainability.

The 3D Printing Edge

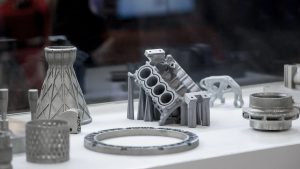

So, how does 3D printing fit into the picture? The answer lies in precision and efficiency. Additive manufacturing, or 3D printing, allows the exact proportions of different metals to be carefully controlled. This is achieved by rapidly melting metals in powdered form using a powerful laser and layering them with finesse.

This advantage of 3D printing opens up a world of possibilities in creating custom superalloys with specific properties, tailored to particular applications. It presents a potential solution to the ongoing challenge in materials science. Optimising the composition of elements in superalloys to yield desired properties has always been a significant challenge, and 3D printing seems a promising solution.

Tested at 800°C (1472°F) – a common temperature in, for example, power plant turbines – the researchers’ 3D printed superalloy demonstrated superior strength and lightness when compared to others designed for similar purposes using other manufacturing methods. This marks a significant breakthrough. The potential applications in various sectors, particularly in aerospace where materials need to withstand extreme temperature variations while maintaining strength and lightness, could be truly revolutionary.

Furthermore, the researchers used computer models designed to predict how certain combinations of elements would behave to help design the superalloy, ensuring its remarkable performance. This predictive power through modelling could be leveraged to design novel superalloys in the future, making the process more efficient and less reliant on trial and error.

However, the researchers recognise that challenges still persist. A crucial aspect that needs to be addressed is the scalability of the 3D printing process to accommodate mass production of such superalloys. The process also needs to ensure that the final product doesn’t contain micro-scale cracks which does seem to be a slight problem.

Looking Ahead

With great examples of research like this being increasingly common, it is clear that 3D printing continues to push the boundaries of what is possible in material science. With the recent creation of this superalloy, we are just scratching the surface of what additive manufacturing can contribute to the development of new materials.

At Additive-X, we’re excited about the future of 3D printing and its potential to revolutionize industries with the creation of novel superalloys. We will continue to be at the forefront of this technology, providing innovative solutions and driving the industry forward. Superalloys and 3D printing are yet another testament to the transformative potential of additive manufacturing.

Interested in buying a 3D printer of your own? Or perhaps you’re interested in us printing a part for you and then sending it over? Come and take a look at our products and services here at Additive-X.