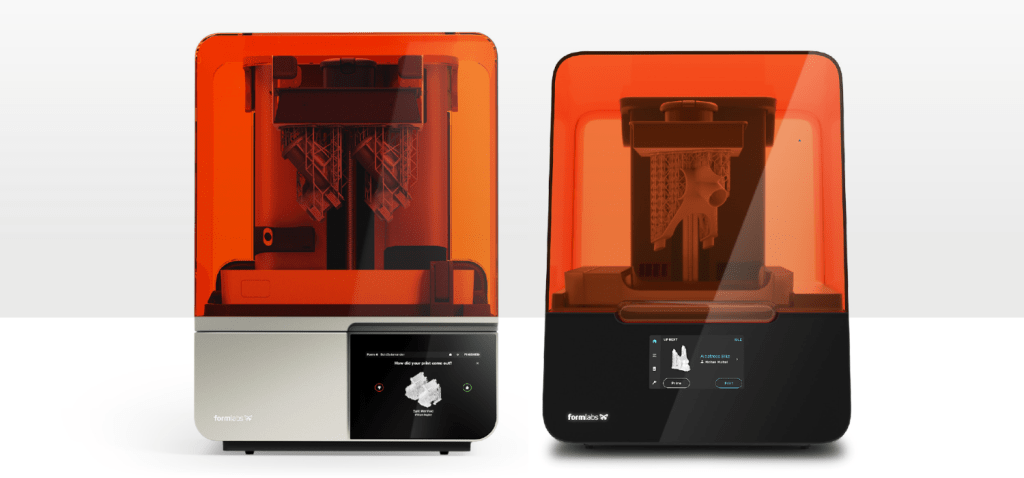

The Formlabs Form 4 is the successor to the Form 3+, ushering in a completely new approach for resin-based desktop 3D printing.

While the Formlabs Form 3+ was an iterative improvement over the Formlabs Form 3 with laser-based LFS (Low Force Stereolithography) technology, the new Form 4 uses Masked Stereolithography (MSLA) with LFD (Low-Force Display) technology.

This fundamental shift was necessary to achieve dramatically faster print speeds while maintaining the high-quality surface finish and reliability that professional users demand.

Check out the models:

- Form 4 Basic Package

- Form 4 Premium Package

- Discover all Formlabs products

What Sets the Form 4 Apart

Print speeds are now two to four times faster than previous models, with most prints completed in under two hours. The build volume has increased by 30%, offering 5.25 litres of printable space compared to the Form 3+’s 4.05 litres.

Its new automatic resin handling system has 5-10 times faster filling rates and more efficient cartridges that use 63% less plastic while maintaining the same 1-litre capacity.

Quality hasn’t been sacrificed for speed — the Form 4 achieves ±0.15% XY dimensional tolerances and features a 50 μm pixel size with pre-tuned anti-aliasing for exceptional detail.

The redesigned Flexible Film Resin Tank now lasts over 75,000 layers and costs 33% less than previous versions.

These improvements, combined with six integrated control systems for monitoring temperature, resin levels, and print forces, make the Form 4 the most reliable and efficient professional resin printer Formlabs has ever produced.

Technological Evolution

The Form 3+ used Low-Force Stereolithography (LFS), employing a laser and galvanometer system to trace each layer. This approach, while precise, was inherently limited by the need to draw each layer point by point.

The Form 4’s LFD technology represents a fundamental shift. It uses a powerful Backlight Unit with 60 LEDs and collimating lenses to project an entire layer at once through a high-resolution LCD.

The new system delivers an industry-leading optical power intensity of 16 mW/cm². The Light Processing Unit (LPU) 4 features specialised polarisers and optical coatings, while a proprietary Release Texture prevents resin suction issues common in other resin printers. Plus, it can print up to 1.9 million layers before replacement.

Why Discontinue the Form 3+?

The Form 3+ is being discontinued because the Form 4’s technological advantages make it obsolete. The new MSLA approach delivers superior results across every metric that matters to professional users: speed, reliability, accuracy, and cost-effectiveness.

While the Form 3+ remains compatible with Formlabs’ resin library, its slower print speeds and higher operating costs make it difficult to justify when the Form 4 offers such significant improvements.

Is the Upgrade Worth It?

For professional users, upgrading to the Form 4 is a compelling proposition.

You’ll immediately notice the dramatic reduction in print times, helping you iterate designs faster or increase production output.

The larger build volume and improved reliability also mean you can confidently take on more ambitious projects – perfect for 3D printer service bureaus, manufacturing operations, and design firms where time is money.

The reduced operating costs from longer-lasting tanks and more efficient material usage help offset the investment.

With the same high-quality surface finish and accuracy you expect from Formlabs, plus new features like integrated cameras for remote monitoring, the Formlabs Form 4 represents a significant step forward in professional resin printing capability.