While you can rely on Bambu Studio’s preconfigured profiles for most of your prints, calibrating your Bambu Lab filament can improve your build-critical parts.

If you need top-notch precision, this extra step will help you achieve the best possible results from your Bambu Lab printer by optimising flow rates, pressure, and temperature settings.

Join us below for a quick guide to filament calibration with Bambu Lab filament.

Why Calibration Matters

Each Bambu Lab filament has its unique polymer blend and additives, resulting in varying printing characteristics. For instance, PLA prints differ from ABS, and even filament colours can behave differently. Calibration ensures your printer adapts to these variations, producing consistent, high-quality prints across all materials.

Related: Bambu Lab Printer Comparison: Find The Right Desktop Printer

Creating custom filaments

Bambu Lab lets you create custom filaments in Bambu Studio. You specify filament settings and colours, which are applied by slicing. Your print job will follow the settings you specify.

There are two methods for creating custom filaments:

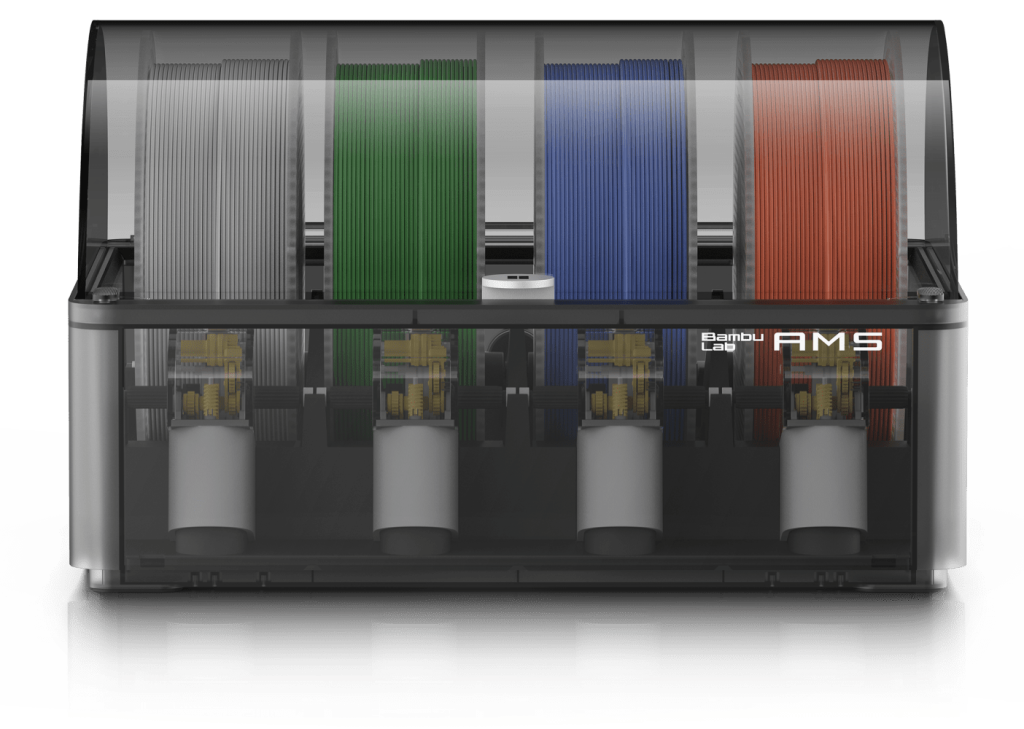

- (Harder)—Use the Custom Filaments feature to create new filaments from scratch or by copying existing presets. You can specify vendor, type, and name, then select a base filament and compatible printers. This feature is best for batch creation of presets for multiple printers and syncing with AMS.

- (Easier)—Modify existing filament settings and save as a new preset. However, this method is limited to one printer preset at a time and can’t be synced to the printer or AMS. Both methods have advantages, with method one offering more comprehensive customisation and integration with the printer system.

Flow Dynamics Calibration

Flow Dynamics Calibration in Bambu Lab printers optimises filament extrusion by compensating for pressure delays.

The X1 series printers use lidar scanning to analyse calibration lines, while the A1 series printers use an eddy current sensor to detect extrusion pressure.

The flow dynamics feature essentially determines ideal extrusion parameters for each filament type, improving print quality, especially during speed changes.

This matters when using new filaments, after nozzle changes, or when filament conditions change. It’s most useful for X1 and A1 series printers, which can automatically calibrate.

The process generates a “K value” that the printer uses to adjust extrusion behaviour. Depending on the printer model, calibration can be done manually or automatically.

Calibration is recommended when introducing new filaments, after nozzle wear or replacement, and when filament properties change due to moisture.

The calibration results are saved in the printer for future use, ensuring consistent print quality across different materials and conditions.

While not always necessary, flow dynamics calibration can improve your 3D print outcomes, especially for complex and high-quality prints.

Further reading: Bambu Lab AMS: A Step-by-Step Guide to Setting Up AMS