Manufacturing hollow plastic packaging and consumer products is faster and easier with moulds fabricated using Formlabs 3D printers. Unlike traditional blow moulding, which relies on expensive metal moulds and lengthy production times, rapid blow moulding uses 3D-printed moulds to create prototypes and low-volume production parts quickly and cost-effectively.

The speed and flexibility of 3D printing enable you to produce functional, high-quality plastic parts in a fraction of the time and cost of conventional methods.

Formlabs’ role in blow moulding innovation

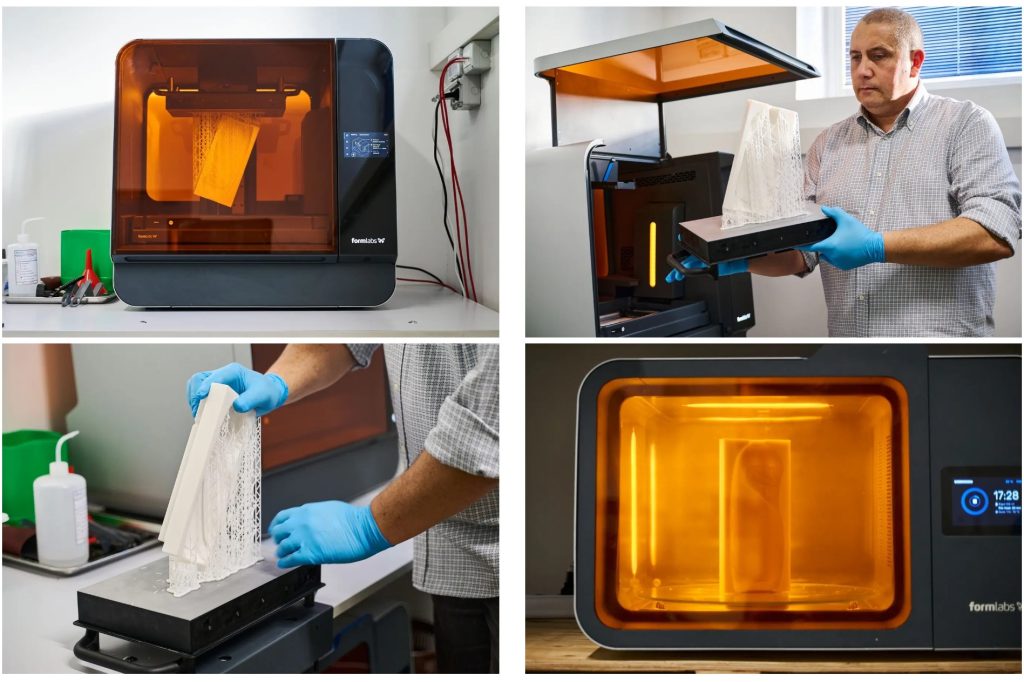

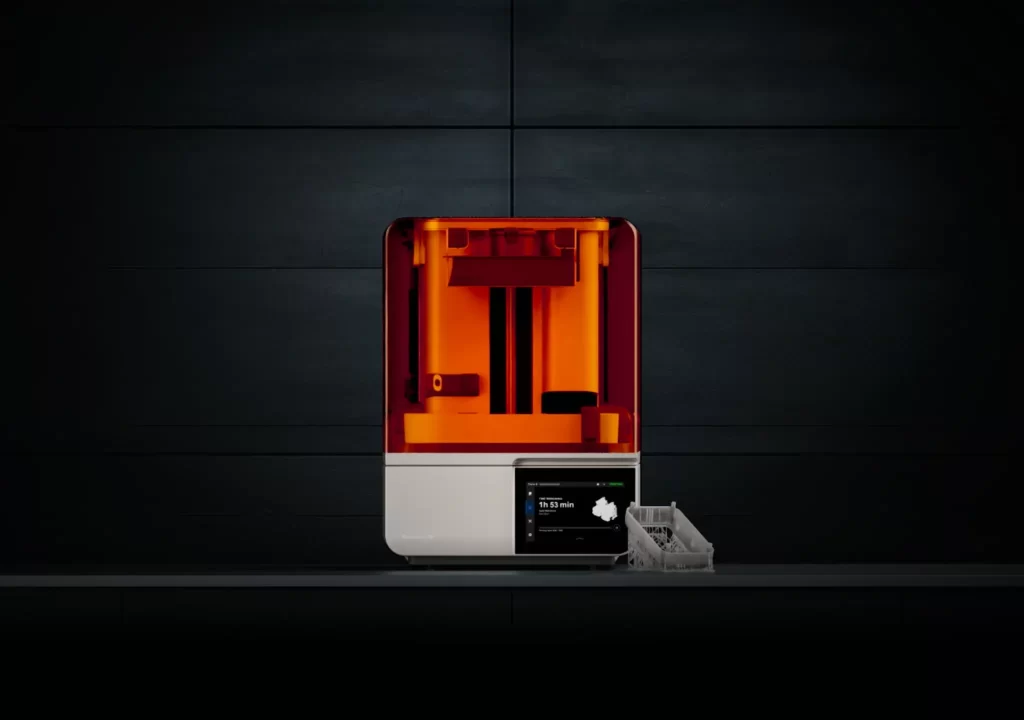

Formlabs is the leading player in desktop 3D printers suitable for blow moulding. Its stereolithography (SLA) 3D printers, particularly the Form 3+ and Form 4, produce moulds suitable for stretch blow moulding (SBM) processes.

These printers are an advancement on standard SLA and use specialised engineering resins like Rigid 10K, which offers the strength, stiffness, and thermal resistance necessary to withstand the demands of blow moulding operations.

The Form 4 is Formlabs’ newest model, a new category of masked SLA printer (MSLA) with a Low Force Display (LFD) print engine for superior performance.

MSLA brings substantial speed improvements. The average speed across all materials is 40 mm/hour, compared to Form 3’s 11 mm/hour. The Form 4 reaches 100 mm/hour at maximum capacity, outpacing Form 3’s 31 mm/hour.

Real-world examples of rapid blow moulding

Unilever transformed its packaging development using Formlabs 3D-printed moulds for SBM, revolutionising its prototyping process.

Dramatic reductions in lead times saw prototype production plummet from 6-12 weeks to 2 weeks. Daily output soared to 200 functional bottle prototypes, each closely resembling production-quality parts.

Rapid design iterations, realistic consumer testing samples, and early production line validation catapulted Unilever’s products to market faster while minimising development risks.

Regardless of your industry, you can harness this game-changing approach to slash costs and turbocharge product launches.

Advantages of 3D printed moulds

Adding 3D printed moulds into your blow moulding workflows dramatically improves production efficiency and cost-effectiveness:

- Lead time reduction: Unilever reported cutting lead times by up to 70%.

- Cost savings: Unilever cut tooling costs by up to 90% compared to traditional metal moulds.

- Increased design iterations: Multiple designs can be tested simultaneously, accelerating product development cycles.

- Faster time-to-market: Rapid prototyping and testing allows you to bring products to market more quickly.

- Risk mitigation: Early testing with production-quality parts reduces the likelihood of costly design flaws in final products.

Applications of rapid blow moulding with 3D printed moulds

The versatility of rapid blow moulding with 3D printed moulds has found applications across various industries:

Consumer goods packaging

Companies like Unilever use this technology to develop and test new personal and home product bottle designs.

Food and beverage containers

Rapid prototyping of bottles and containers for the food industry, allowing for quick design validation and consumer testing.

Cosmetic packaging

Developing unique and visually appealing packaging designs with custom inserts for cosmetic and beauty products.

Medical devices

Creating prototypes and small-batch production runs for medical containers and devices that wouldn’t be commercially viable otherwise.

Industrial parts

Manufacturing of custom fluid containers and hollow parts for industrial applications to reduce dependence on third-party suppliers.

Find out more

Even if your manufacturing workflow operates well with traditional blow moulding, 3D printing can significantly accelerate your product development cycles, reduce costs, and help bring innovative designs to market faster than ever before.

If you’re interested, contact the Additive-X team to discover rapid blow moulding solutions for your business using Formlabs 3D printers.

Top image credit: Formlabs