Eufymake Printer Review: What Makes It a Standout Option?

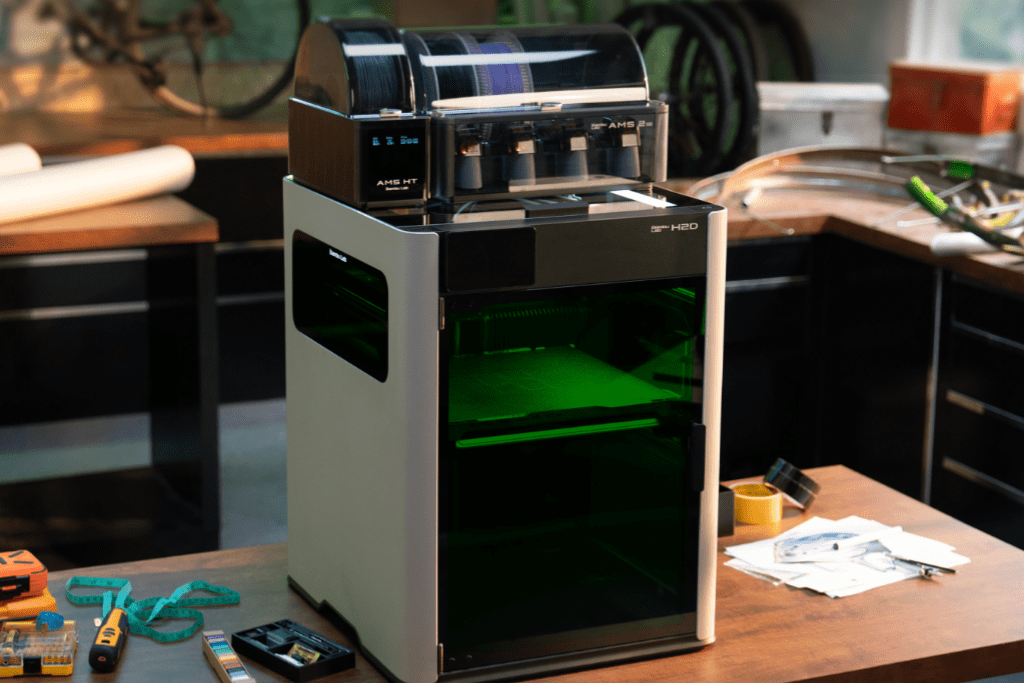

When it comes to modern printing solutions, businesses and makers need equipment that is fast, reliable, and flexible enough to handle different applications. In this Eufymake printer review, we’ll break down why the system has become an attractive option for professionals, researchers, and creative users who want production-quality results without

Eufymake Printer Review: What Makes It a Standout Option? Read More »