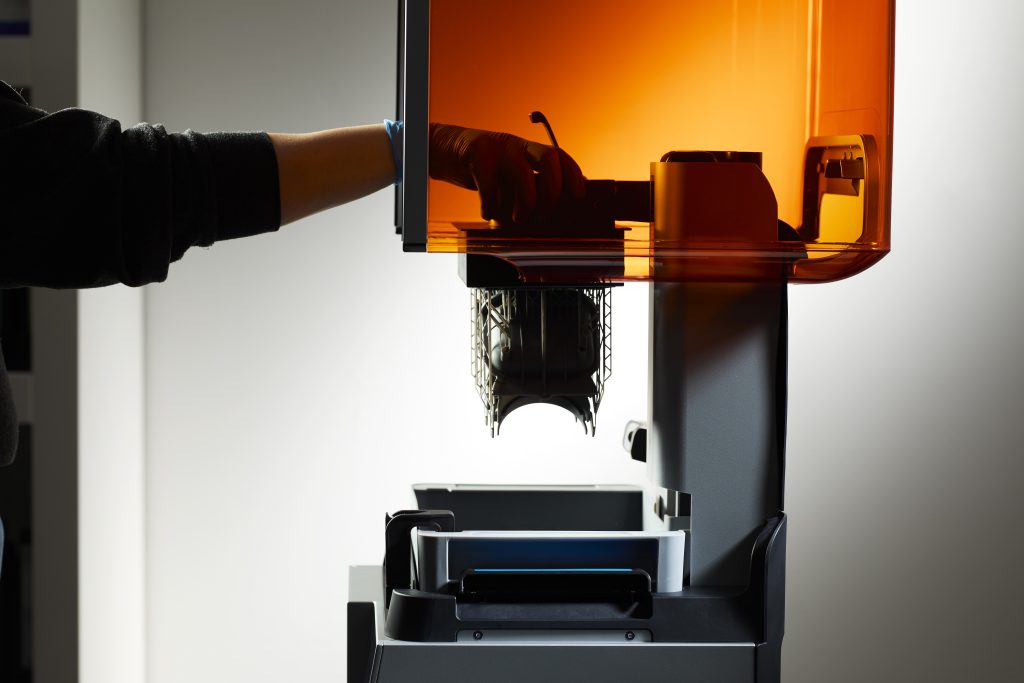

Your Formlabs printer creates exceptional parts with essential maintenance to keep it running at peak performance. Regular care maximises uptime and ensures consistent print quality, whether daily or monthly.

Form 4 printers operate up to four times faster than previous models, completing most jobs in about two hours. Simple maintenance routines help maintain these impressive speeds.

Join us below for essential maintenance tips. Rather watch a video? Here you go:

Between-print maintenance tasks

Check your build platform after every print job for uncured resin and sticky residue that could affect future prints. To remove liquid resin, wipe the platform with isopropyl alcohol and paper towels, while a metal scraper works best for hardened deposits.

That simple five-minute habit prevents adhesion problems and extends the life of your build surface.

Inspect resin cartridges for leaks around the skirt and rubber bite valve before loading them into your printer.

Leaking cartridges cause messy spills and contaminate internal components, leading to print failures. Check cartridge expiry dates printed on the bottom sticker, as most resins have a 24-month shelf life from the production date.

Resin tank care fundamentals

Examine your resin tank before each print for debris, scratches or damage to the transparent film. Small cured fragments floating in the tank can puncture the film during printing, causing leaks and print failures.

The plastic scraper included with your printer works safely to remove debris without damaging the delicate film surface. The printer’s built-in cleaning sheet utility can also be used to eliminate debris in the resin tank.

Store tanks correctly on flat surfaces with lids securely attached when not in use. Light exposure cures resin prematurely, so always keep tanks covered and away from windows or bright light sources.

Tank films wear gradually with normal use, requiring replacement after printing between 600,000 and 1,900,000 layers, depending on material and layer thickness.

Safe resin changeover procedures

When switching between resin types, thoroughly clean all components that come into contact with resin to prevent cross-contamination.

Pay special attention to the mixer assembly, as residual resin can affect material properties and cause unexpected print failures. Release the latch securing the mixer to extract it from the printer for cleaning.

Soak mixers in isopropyl alcohol or TPM (tripropylene glycol monomethyl) ether to dissolve resin residue. Allow the mixer to dry entirely before reinstallation, especially when using solvents evaporating slowly.

Proper cleaning prevents unexpected chemical reactions between different resin formulations that could damage your printer or ruin prints.

Critical airflow maintenance

Your Form 4 printer relies on adequate airflow to prevent overheating during operation. The rear mesh filter collects dust that restricts cooling to critical components, causing print failures or shortened component lifespans. Access this filter through the magnetic cover on the back panel near the power switch.

Vacuum the mesh filter monthly or whenever visible dust accumulates. The filter does not require replacement parts or consumables but does need regular cleaning to maintain proper airflow.

Poor cooling mainly affects the Light Processing Unit, which needs stable temperatures for consistent curing and accurate prints.

Software updates and firmware maintenance

Check regularly for PreForm software updates through the Help menu. Updated software provides compatibility with new resins, improved support generation and bug fixes that enhance printing success rates.

The software connects automatically to Formlabs servers when online but supports manual updates for offline environments.

You can update printer firmware through PreForm by expanding the right panel and clicking on your printer name to access the Printer Details window.

Firmware updates enhance your printer’s performance with bug fixes, improved resin dispensing algorithms and better temperature control. Always complete firmware updates when prompted to avoid compatibility issues.

Print failure prevention strategies

Poor adhesion to the build platform causes most print failures. When prints fail to stick correctly, inspect the Light Processing Unit for dust or residue that could interfere with curing.

Ensure the printer reaches the correct operating temperature before printing to avoid adhesion problems.

Use PreForm’s layer viewer tool to check the first layer and verify good contact between your part and the build platform. Parts with too small or narrow bases may require reorientation or additional supports to prevent separation during printing.

Component inspection and cleaning

Examine the z-axis lead screw by removing the build platform, tank and cartridge while the printer remains unplugged.

Turn the screw by hand, feeling for rough spots or inconsistent motion that could affect print quality. Clean the screw with a lint-free cloth to remove debris, and apply a light coating of lithium grease designed for bearings if necessary.

When contaminated, the light processing unit requires careful cleaning. First, remove dust with dry PEC*PADs and a rubber blow bulb, then use minimal isopropyl alcohol for stubborn residue.

Wipe the release texture with slow, straight movements from side to side until all contamination disappears. Avoid excessive pressure that could damage the sensitive texture.

Troubleshooting resin flow issues

When your printer hesitates during filling or fails to dispense resin, check that the cartridge vent cap remains open.

Closed vents prevent air replacement as resin dispenses, creating a vacuum lock inside the cartridge.

Remove stubborn cartridges and squeeze the black rubber bite valve several times against the hard shell until it opens fully. Resin tanks showing error messages like “Tank missing” or “Tank not locked” need proper positioning.

Ensure both latches on the tank are fully closed, and the tank sits securely in its housing. Before contacting support, try alternative tanks to determine whether the issue stems from the tank or printer recognition system.

Documentation practices for support cases

Maintain records of printer performance, noting any unusual sounds, movements or error codes. When contacting Formlabs support, provide your printer’s serial name on the back panel in the format “Form4-AdjectiveAnimal”, along with resin type and batch number.

Document troubleshooting steps you have attempted, such as tank inspection, build platform cleaning or firmware updates. Include relevant Form files and details about previous successful prints of the same model.

Regular maintenance prevents most issues before they affect your print quality or damage components. These simple procedures extend your Formlabs printer’s working life while maintaining the precision and reliability that make these machines industry standards.

Call us on 01765 694 007 or email [email protected] for assistance with Formlabs resin printer maintenance.

Additional reading: Form 4 3D Printer Maintenance: Best Practices