Bambu Lab H2D 3D Printer: Power of Versatility in Material Choice

If you use 3D printing in your business, you understand how crucial material choice is for achieving the right results. The Bambu Lab H2D 3D Printer is an innovative tool that offers versatility, enabling you to take full control over your material selection and get the best performance for every project. Whether you’re prototyping, producing custom parts, or creating products with specific performance needs, this printer can help you elevate your output. The H2D is designed to support a range of materials that let you tailor your prints to meet specific business demands.

Understanding the Importance of Material Selection for Your Business

When you rely on 3D printing for your business, the material you choose has a direct impact on your product’s quality, durability, and functionality. Different projects require different materials, and knowing how to select the right one is crucial to unlocking your printer’s full potential. You need materials that support your workflow, keep costs manageable, and meet the specific requirements of each part you’re printing.

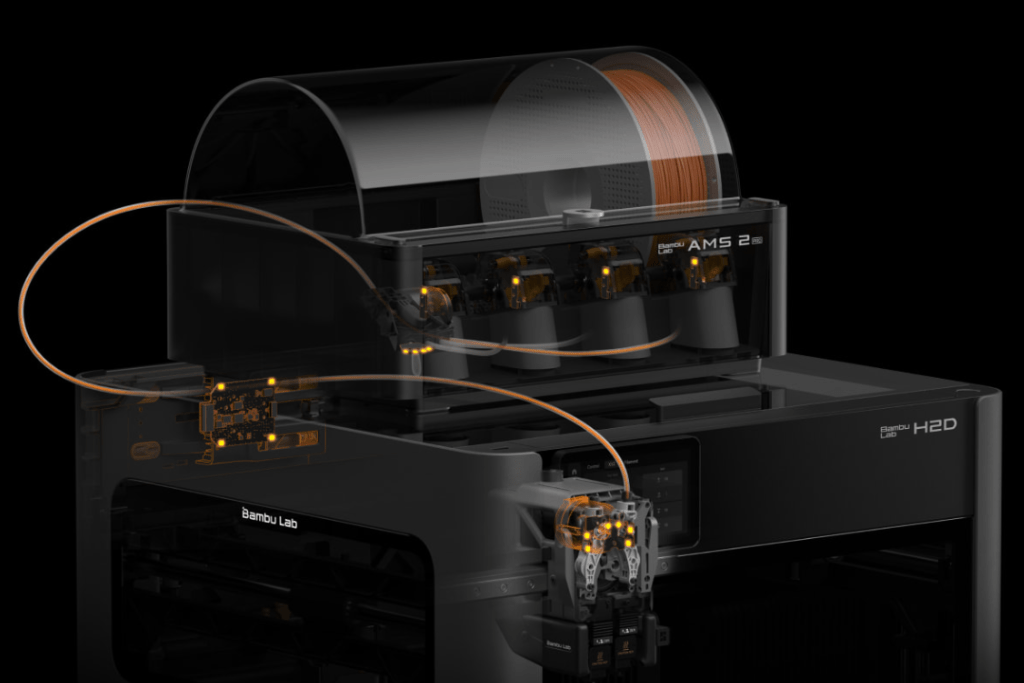

The Bambu Lab H2D excels in material compatibility, offering seamless transitions between filaments. This flexibility allows you to work efficiently, without needing to switch to multiple machines or reconfigure your setup. With this printer, you can handle everything from high-volume production to intricate, specialized parts, all while keeping your costs under control.

Streamlining Your Workflow with the H2D’s Material Compatibility

If you need to quickly adapt to different materials in your production process, the Bambu Lab H2D will save you time and effort. The printer is compatible with an extensive range of materials, and its upgradeable features, such as the laser cutter module, mean you can work with even more materials and add value to your products with custom cutting and engraving.

Explore the Key Materials Supported by the H2D

Here’s a look at the materials the Bambu Lab H2D can print with and how each one can enhance your business:

- PLA (Polylactic Acid)

If you need quick results, PLA is your go-to material. It’s easy to print, eco-friendly, and delivers smooth finishes. Perfect for prototypes or models that need to be produced quickly.

Applications: Rapid prototyping, concept models, display pieces.

Benefits: Easy to print, low warping, biodegradable. - ABS (Acrylonitrile Butadiene Styrene)

For parts that require strength and heat resistance, ABS is the material to choose. It’s perfect for mechanical components that need to withstand wear and tear.

Applications: Automotive parts, functional components, consumer goods.

Benefits: High impact resistance, heat resistance. - PETG (Polyethylene Terephthalate Glycol)

PETG combines the benefits of both PLA and ABS, strength, flexibility, and ease of use. It’s ideal for durable prototypes.

Applications: Automotive parts, functional prototypes, containers.

Benefits: Excellent adhesion, chemical resistance, minimal warping. - TPU (Thermoplastic Polyurethane)

Need flexibility? TPU is ideal for products that need to bend, stretch, and remain durable.

Applications: Wearables, phone cases, medical devices.

Benefits: Flexible, durable, abrasion-resistant. - Nylon

If your parts need strength and wear resistance, Nylon is the material for you. It’s perfect for high-stress applications.

Applications: Gears, bearings, automotive components.

Benefits: Extremely durable, chemical-resistant. - Carbon Fibre Reinforced Filaments

Looking for strength without the weight? Carbon fibre-reinforced filaments offer a lightweight yet strong solution for demanding applications.

Applications: Drone frames, automotive parts, aerospace components.

Benefits: Strong, lightweight, abrasion-resistant. - Wood Fill & Metal Fill Filaments

Want to add a premium look to your projects? These give your parts the look and texture of traditional materials, giving your prints a unique aesthetic.

Applications: Custom furniture, artistic products.

Benefits: Creative potential, premium finish.

Dual Functionality: 3D Printing and Laser Cutting Combined

One of the standout features of the Bambu Lab H2D is its ability to integrate 3D printing and laser cutting. With the optional laser cutter module, you can cut and engrave materials like wood, acrylic, and leather, expanding your capabilities and allowing you to produce even more intricate and customized items. This makes the H2D a truly all-in-one tool for your business.

Choosing the Right Material for Your Needs

To maximize your 3D printing investment, consider the following when choosing materials:

- Functionality: Match the material to the end use. For prototypes, PLA works well, while functional parts may require materials like Nylon or ABS.

- Speed and Efficiency: Some materials, such as PLA, print faster and require less post-processing. If you need quick turnarounds, consider PLA or PETG.

- Sustainability: If your business values sustainability, opt for eco-friendly materials like PLA or recycled PETG.

- Cost-Effectiveness: PLA is affordable for high-volume printing, but for speciality parts, materials like Nylon or Carbon Fibre may be worth the investment.

Unlock Your Business’s Potential with the Bambu Lab H2D

The Bambu Lab H2D is a game-changer for businesses looking to streamline their 3D printing operations. Its versatility in supporting a wide range of materials, along with the ability to upgrade with a laser cutter, provides unmatched flexibility and efficiency. With the H2D, you can tackle any project, from prototyping to production, while maintaining the highest quality standards.

If you’re ready to take your 3D printing to the next level, explore the Bambu Lab H2D and its material capabilities. Visit our shop page for more details, and check out our blog for additional tips and industry insights. Happy printing!