The world of movie prosthetics and special effects makeup has traditionally turned to techniques like sculpting, moulding, and casting to bring fantastical creatures and gruesome injuries to life. However, over the past decade, 3D printing has stormed the industry to become a dominant digital fabrication technique.

3D printing is used on today’s biggest blockbusters and TV shows, allowing artists to prototype and iterate rapidly from the early concept stages through to screen-ready prosthetics. Effects teams are also using 3D printing to create sturdy props, armour, and costume elements that capture immense detail.

Transformative technology

The rise of 3D printing marks a seismic shift in how special effects makeup artists and prop builders approach their craft. New design freedoms, intense detail, and rapid iteration afforded by additive manufacturing fundamentally change their creative process.

Effects teams now digitally model limbs, wounds, and other prosthetic designs directly in 3D software. Artists explore more radical, intricate concepts without technical constraints holding them back. They validate what works early with 3D printed prototypes instead of waiting weeks after traditional sculpting and mould making.

3D printing enables artists to unlock unprecedented texture intricacy with designs impossible to sculpt by hand. Completely new micro details emerge, like subtle skin pores on the creature’s face and uncanny dilated blood vessels on gaping wounds. Effects reflect anatomy studies more accurately.

Streamlined 3D printing rapidly turns around revised versions of face prosthetics, body parts, and prop weapons on set. Directors get to evaluate looks and feel with performers much earlier and still request tweaks as filming progresses.

Makeup and effects transform from afterthoughts to collaborative, integral storytelling tools pushing what’s visually possible week-to-week.

Powerful examples from movies and TV

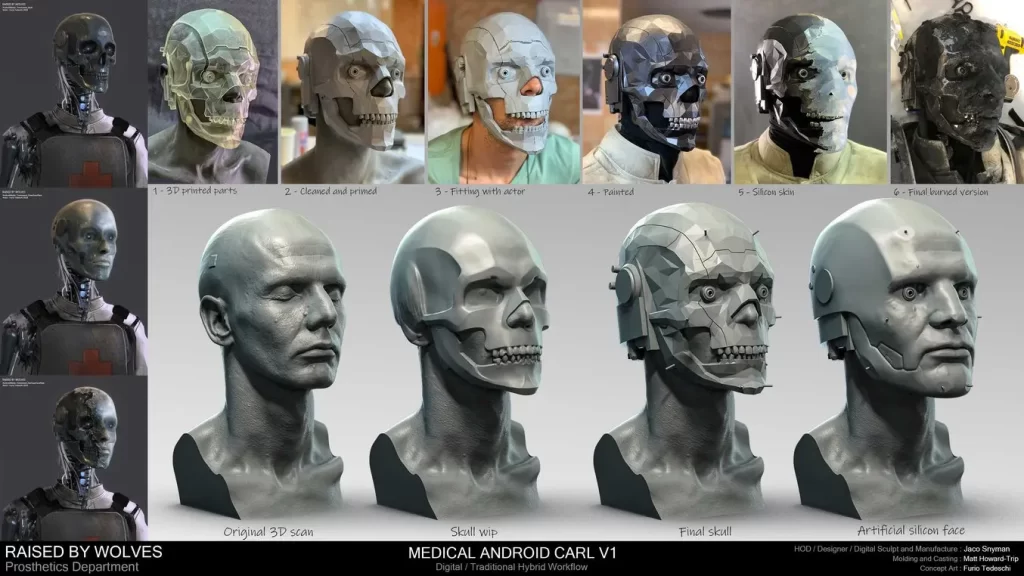

Some powerful examples that demonstrate 3D printing’s growing role include “Black Panther: Wakanda Forever,” “The Whale,” A24’s “Marcel the Shell with Shoes On”, and “Raised by Wolves”.

In “Raised by Wolves” (the TV Series from 2020–2022), Formlabs 3D printers were used to 3D print several props and prosthetics, including the creature fetus, prosthetic makeup, and practical effects.

In “Wakanda Forever,” legendary costume designer Ruth E. Carter employed 3D printing to make durable, flexible costumes and armour that incorporated influences from Mesoamerican cultures. Her team 3D printed jewellery, crowns, and other ornate pieces that had to adequately withstand water environments.

3D printing enabled the makeup team for “The Whale” to realistically transform Brendan Fraser into a 600-pound man with large fat suits and facial prosthetics. They carefully matched the silicone appliances to the contours of Fraser’s face based on 3D scans. The transformative role garnered Fraser an Oscar nomination for Best Actor.

On a smaller scale, the team behind the Oscar-nominated stop-motion film “Marcel the Shell with Shoes On” relied on 3D printing to create the film’s tiny star – they used 3D scanning and printing for the two-inch seashell character, providing consistency across shots while still matching the delicate aesthetics needed.

Top 3D Printing Technologies for Movie F/X

From emulating heavy fat suits to recreating the finest crackle patterns on a tiny seashell, advanced 3D printing processes enable Hollywood’s best practical effects.

Two of the most common technologies used are stereolithography (SLA) and fused filament fabrication (FFF).

SLA Printing

SLA 3D printing uses ultraviolet lasers to cure liquid resin layer-by-layer with very high accuracy and smooth finishes. The precision resolution can produce minuscule textures and cracks to mimic everything from skin imperfections to pitting on rusted metal.

Leading SLA 3D printers like the Formlabs Form 3+ and Form 3L give effects studios professional-level parts with minimal hands-on polishing, high accuracy, and surface quality, saving makeup artists substantial time and labour.

FFF 3D Printing

FFF empowers experimentation upstream with affordable thermoplastics and speciality filaments like wood and bronze fill, glow-in-the-dark, and carbon-infused plastics.

Artists can explore shapes and feel with traditional techniques. They can then validate designs rapidly with realistic 3D prototypes. Key finishing details get solidified faster, even before committing to final moulds and casting appliance runs.

Professional-grade Printers like the UltiMaker S5 and Bambu Lab X1 Carbon deliver great performance for ambitious prints on big-budget productions.