Case Study: How Dixon Valve US Uses 3D Printing in Robotic Automation

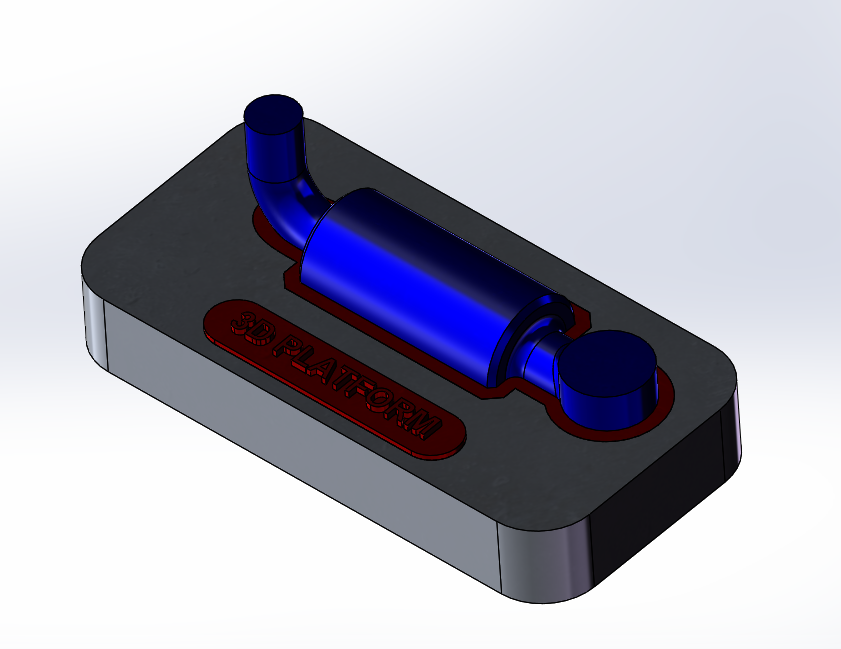

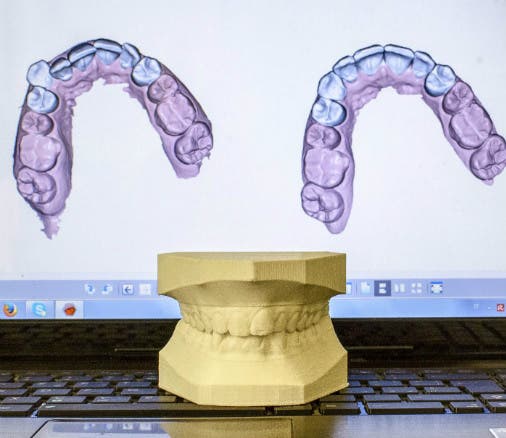

Prior to additive manufacturing, Dixon Valve, a US-based manufacturer of fittings for fluid transfer industries, relied on outsourcing and costly in-house machining processes to produce tools. But thanks to the Markforged Mark Two, they are now able to 3D print their own tools and jaws for industrial robotic arms, saving

Case Study: How Dixon Valve US Uses 3D Printing in Robotic Automation Read More »